Toyota Sienna Service Manual: Reassembly

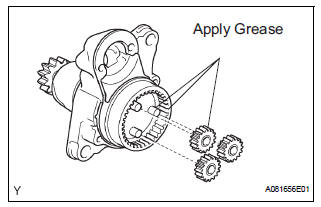

1. INSTALL PLANETARY GEAR

(a) Apply grease to the planetary gears and pin parts of the planetary shaft.

(b) Install the 3 planetary gears.

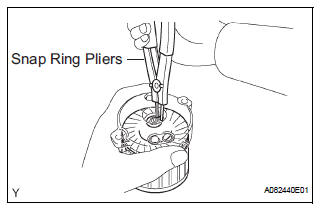

2. INSTALL STARTER ARMATURE ASSEMBLY

(a) Apply grease to the plate washer and the armature shaft.

(b) Install the starter armature to the starter commutator end frame.

(c) Using snap ring pliers, install the plate washer and a new snap ring.

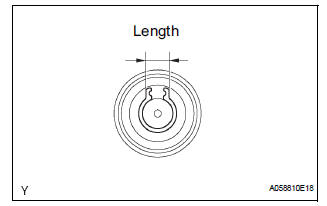

(d) Using a vernier caliper, measure length of the snap ring.

Maximum length: 5.0 mm (0.197 in.) If the length is greater than the maximum, replace it with a new snap ring

3. INSTALL DRIVE HOUSING STARTER BEARING COVER

(a) Install the drive housing starter bearing cover to the starter commutator end frame.

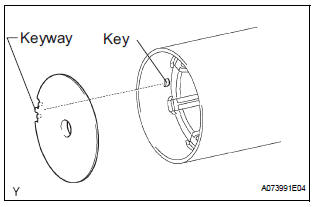

4. INSTALL STARTER ARMATURE PLATE

(a) Insert the starter armature plate to the starter yoke.

(b) Align the keyway of the starter plate with the key inside the starter yoke, and install the starter plate.

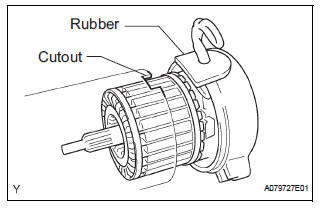

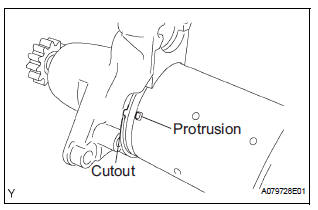

5. INSTALL STARTER COMMUTATOR END FRAME ASSEMBLY

(a) Align the rubber with the convex cutout of starter yoke.

(b) Install starter commutator end frame to the starter yoke.

6. INSTALL STARTER YOKE ASSEMBLY

(a) Align the key of the starter yoke with the keyway of repair service starter kit.

(b) Install the starter yoke with the 2 through bolts.

Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

7. INSTALL REPAIR SERVICE STARTER KIT

(a) Apply grease to the plunger and the hook.

(b) Hang the plunger hook of the repair service starter kit to the drive lever.

(c) Install the plunger and return spring.

(d) Install the repair service starter kit with the 2 screws.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf)

(e) Connect the lead wire to the repair service starter kit with the nut.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

Inspection

Inspection

1. Inspect starter assembly

NOTICE:

These tests must be performed within 3 to 5 seconds

to avoid burning out the coil.

(a) Perform the pull-in test.

(1) Disconnect the lead ...

Installation

Installation

1. INSTALL STARTER ASSEMBLY

(a) Install the starter with the 2 bolts.

Torque: 37 N*m (380 kgf*cm, 26 ft.*lbf) for bolt

(b) Connect the starter connector.

(c) Install the terminal nut a ...

Other materials:

Installation

1. INSTALL SHOCK ABSORBER ASSEMBLY REAR LH

(a) Install the rear spring bumper No.1 LH to the shock

absorber assembly LH.

(b) Support the rear axle beam assembly with a jack.

(c) Install the rear shock absorber assembly rear LH,

cushion retainer and nut to the rear axle beam.

(d) ...

DTC check / clear

HINT:

Illustrations may differ from the actual vehicle depending

on the device settings and options. Therefore, some

detailed areas may not be shown exactly the same as on

the actual vehicle.

If the system cannot enter the diagnostic mode, inspect all AVC-LAN

communication ...

Disassembly

1. REMOVE BRAKE MASTER LESS RESERVOIR TANK CYLINDER SUB-ASSEMBLY

(a) Using soft jaws on the vise, hold the brake master

cylinder in a vise through aluminum plates.

(b) Using a screwdriver, remove the O-ring.

(c) Using SST, remove the brake tube from the brake

master cylinder.

SST 09023 ...