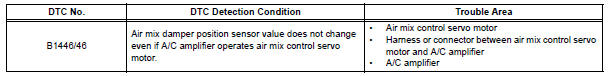

Toyota Sienna Service Manual: Air Mix Damper Control Servo Motor Circuit (Driver Side)

DESCRIPTION

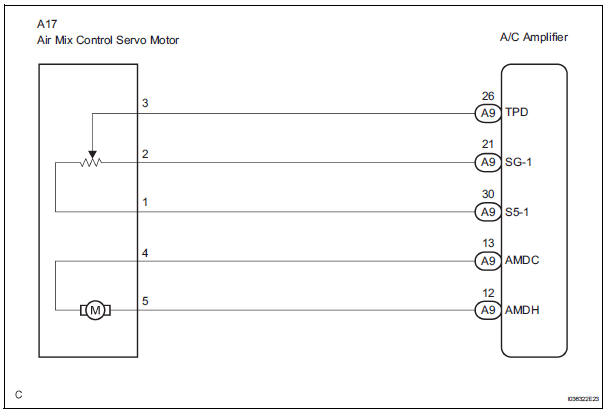

The air mix control servo motor (air mix damper servo sub-assembly) is controlled by the A/C amplifier.

The air mix control servo motor moves the air mix damper by rotating (normal, reverse) with electrical power from the A/C amplifier.

This adjusts the mix ratio of the air that passes through the evaporator and heater core and controls the air flow temperature. Air flow temperature changes when moving the air mix damper to the target point.

The target point can be detected by the air mix damper position sensor.

WIRING DIAGRAM

INSPECTION PROCEDURE

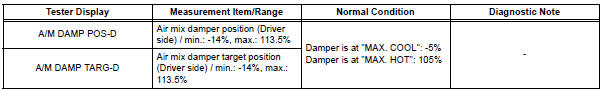

1 READ VALUE OF INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the items below in the DATA LIST, and read the display on the intelligent tester.

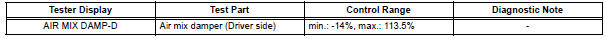

DATA LIST / AIR CONDITIONER

OK: When the target position is "MAX. COOL" (-5%), the actual opening angle is 19.0% or less.

When the target position is "MAX. HOT" (105%), the actual opening angle is 81.0% or more.

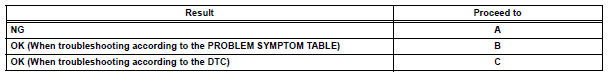

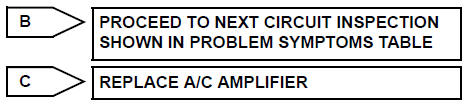

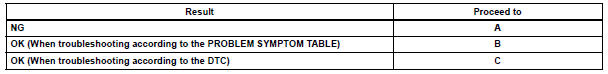

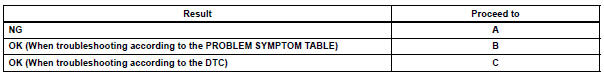

Result

2 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the item below in the ACTIVE TEST and then check the air flow temperature by hand.

ACTIVE TEST / AIR CONDITIONER

OK: When the lever is moved to the "MAX. HOT" side, warm air comes out.

When the lever is moved to the "MAX. COOL" side, cool air comes out.

Result

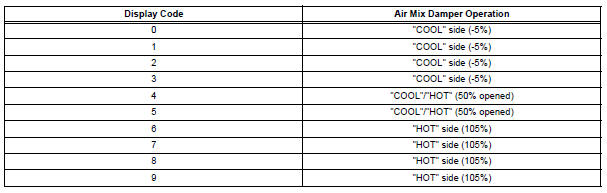

3 PERFORM ACTUATOR CHECK

(a) Enter the actuator check mode (See page AC-15).

(b) Press the DEF switch and change to the step operation.

(c) Check the air flow temperature by hand.

OK: Air flow temperature changes in accordance with each display code.

Result

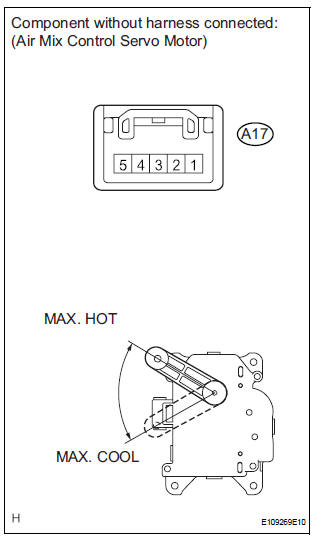

4 INSPECT AIR MIX CONTROL SERVO MOTOR

(a) Remove the air mix control servo motor.

(b) Disconnect the connector from the air mix control servo motor.

(c) Connect the positive (+) lead from the battery to terminal 5 and the negative (-) lead to terminal 4, then check that the lever turns to the "MAX. HOT" position smoothly.

OK: Lever turns to "MAX. HOT" position smoothly.

(d) Connect the positive (+) lead from the battery to terminal 4 and the negative (-) lead to terminal 5, then check that the lever turns to the "MAX. COOL" position smoothly.

OK: Lever turns to "MAX. COOL" position smoothly.

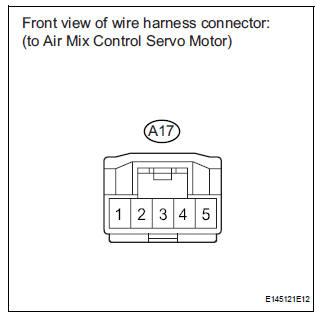

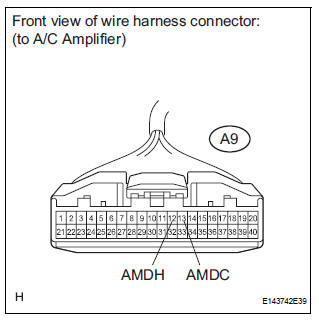

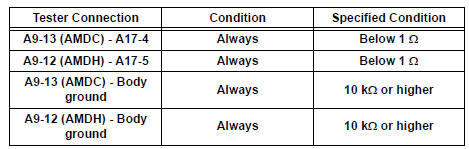

5 CHECK HARNESS AND CONNECTOR (AIR MIX CONTROL SERVO MOTOR - A/C AMPLIFIER)

(a) Disconnect the connector from the A/C amplifier.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

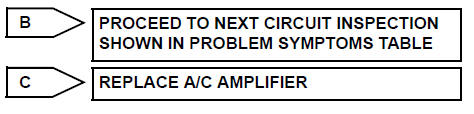

REPLACE A/C AMPLIFIER

Air Outlet Damper Control Servo Motor Circuit

Air Outlet Damper Control Servo Motor Circuit

DESCRIPTION

This circuit turns the servo motor and changes each damper position by

receiving the signals from the A/

C amplifier.

The air outlet damper servo motor switches the air outlet mode ...

Rear Air Mix Damper Control Servo Motor Circuit

Rear Air Mix Damper Control Servo Motor Circuit

DESCRIPTION

The rear air mix control servo motor (water valve servo motor) is controlled

by the A/C amplifier.

The rear air mix control servo motor moves the air mix damper by rotating

(normal ...

Other materials:

DTC check / clear

1. CHECK DTC

Connect the intelligent tester to the DLC3.

Connect the intelligent tester to the Controller

Area Network Vehicle Interface Module (CAN

VIM). Then connect the CAN VIM to the Data

Link Connector 3 (DLC3).

Turn the ignition switch to the ON posi ...

Operation check

1. CHECK WINDOW LOCK SWITCH

Check that the passenger side power window and

slide door power window operation is disabled when

the window lock switch of the power window master

switch is pressed.

Check that the passenger side power window and

slide door power windows can ...

Removal

1. RECOVER REFRIGERANT FROM REFRIGERATION

SYSTEM (See page AC-172)

2. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

3. REMOVE FRONT BUMPER ASSEMBLY (See page

ET-3)

4. DISCONNECT DISCHARGE HOSE SUB-ASSEMBLY

(a) Remove the bolt and disconnect the discharge hose

sub-assembly from the coo ...