Toyota Sienna Service Manual: Disassembly

1. INSPECT PACK CLEARANCE OF FORWARD CLUTCH

HINT: (See page AX-242)

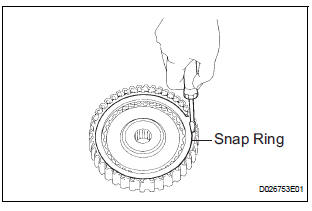

2. REMOVE FORWARD MULTIPLE DISC CLUTCH DISC

(a) Using a screwdriver, remove the snap ring.

(b) Remove the flange, 5 discs and 5 plates from the input shaft assembly.

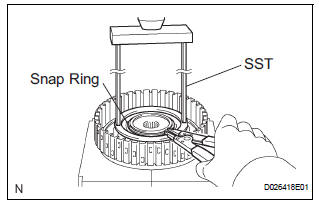

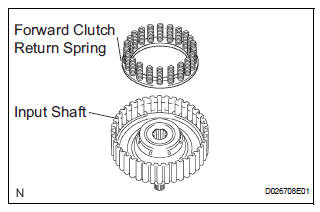

3. REMOVE FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY

(a) Place SST on the spring retainer and compress the return spring with a press.

(b) Using a snap ring expander, remove the snap ring.

NOTICE:

- Stop the press when the spring seat is lowered 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove, preventing the spring seat from being deformed.

- Do not expand the snap ring excessively.

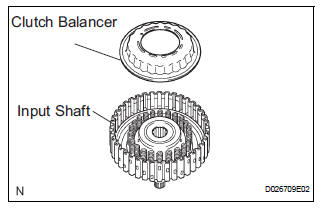

(c) Remove the clutch balancer from the input shaft.

(d) Remove the forward clutch return spring from the input shaft.

4. REMOVE FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY

(a) Place the forward clutch drum onto the oil pump.

(b) Holding the forward clutch piston by hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the oil pump to remove the forward clutch piston.

HINT:

When the piston cannot be removed as it is slanted, blow air again with the protruding side pushed, or remove the piston using the needle nose pliers with vinyl tape on the tip.

5. REMOVE INPUT SHAFT OIL SEAL RING

(a) Remove the input shaft oil seal ring from the input shaft.

Forward clutch

Forward clutch

Components

...

Inspection

Inspection

1. INSPECT PACK CLEARANCE OF FORWARD CLUTCH

(a) Install the forward clutch on the oil pump.

NOTICE:

Be careful not to damage the oil seal ring of oil

pump.

b) Using a dial indicator, measure ...

Other materials:

Open in Driver Side Squib 2nd Step Circuit

DTC B1181/18 Open in Driver Side Squib 2nd Step Circuit

DESCRIPTION

The driver side squib 2nd step circuit consists of the center airbag sensor

assembly, the spiral cable and

the steering pad.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B1181/18 is reco ...

Power steering fluid

Bleeding

1. BLEED POWER STEERING SYSTEM

(a) Check the fluid level (See page PS-2).

(b) Jack up the front of the vehicle and support it with

stands.

(c) Turn the steering wheel.

(1) With the engine stopped, turn the steering

wheel slowly from lock to lock several times.

(d) Lower the ...

Diagnostic trouble code chart

HINT:

If a trouble code is displayed during the DTC check, inspect

the circuit listed for that code. For details of each code, refer

to the relevant page listed under respective "DTC No." in the

DTC chart.

TIRE PRESSURE WARNING SYSTEM:

...