Toyota Sienna Service Manual: Inspection

1. INSPECT FUEL INJECTOR ASSEMBLYV

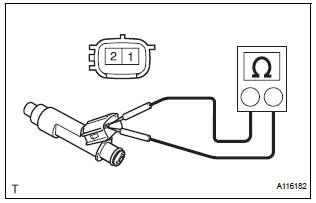

(A) inspect the injector resistance.

(1) Using an ohmmeter, measure the resistance between the terminals.

Standard resistance

If the resistance is not as specified, replace the injector.

(b) Inspect the injection volume.

| CAUTION:

This test involves high-pressure fuel and

electricity. Take every precaution regarding the

safe handling of both fuel and electricity.

Perform this test in a safe area, and avoid any sparks or flames. Do not smoke. |

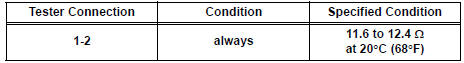

(1) Install the fuel tube connector to SST (hose), then connect the tube connector to the fuel pipe (vehicle side).

SST 09268-31011 (09268-41500, 90467- 13001, 95336-08070)

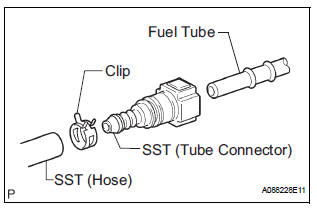

(2) Install the O-ring to the fuel injector subassembly.

(3) Connect SST (adaptor and hose) to the injector, and hold the injector and union with SST (clamp).

SST 09268-31011 (90467-13001, 95336- 08070), 09268-41140, 09268-41400

(4) Put the injector into the graduated cylinder.

| CAUTION: Install a suitable vinyl tube onto the injector to contain gasoline spray. |

(5) Operate the fuel pump (See page FU-7).

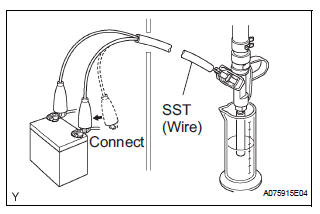

(6) Connect SST (wire) to the injector and the battery for 15 seconds, and measure the injection volume with the graduated cylinder.

Test each injector 2 or 3 times.

SST 09842-30080

Volume: 84 to 100 cm3 (5.1 to 6.0 cu in.) in 15 seconds

Difference between each injector: 16 cm3 (0.98 cu in.) or less

If the injection volume is not as specified, replace the injector.

(c) Check for leakage.

(1) In the condition above, disconnect the tester probes of SST (wire) from the battery and check for fuel leakage from the injector.

Fuel drop: 1 drop or less in 16 minutes

Removal

Removal

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

See page FU-1.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. REMOVE NO. 1 ENGINE UNDER COVER

4. DRAIN ENGINE COOLANT (See page CO-6)

5. REMOVE FR ...

Installation

Installation

1. INSTALL FUEL INJECTOR ASSEMBLY

(a) Apply a light coat of spindle oil or gasoline to new Orings,

and install them to each injector.

(b) Apply a light coat of spindle oil or gasoline where ...

Other materials:

Meter panel light control

The brightness of the meter panel lights can be adjusted.

Pressing the button will adjust the

brightness of the meter panel

lights.

The brightness level of the meters

when the surroundings are bright

(day mode) and dark (night mode)

can be adjusted individually. However,

when in day ...

Diagnostic trouble code chart

1. DTCS FOR OCCUPANT CLASSIFICATION SYSTEM

If a trouble code is displayed during the DTC check,

check the circuit listed for the code in the table below

(proceed to the page listed for that circuit).

HINT:

When DTC B1150/23 is detected as a result of

troubleshooting for the airbag system, pe ...

Fog light switch

The fog lights secure excellent visibility in difficult driving

conditions,

such as in rain and fog.

The illustration is intended as an example.

Turns the fog lights on

*1 or

*2

Turns the fog lights off

*1: For U.S.A.

*2: For Canada

Fog lights can be used when

The headlights ...