Toyota Sienna Service Manual: Inspection

1. INSPECT UNDERDRIVE PACK CLEARANCE

(a) Install the underdrive clutch to the transaxle case.

NOTICE: Be careful not to damage the oil seal rings.

(b) Install a dial indicator as shown in the illustration.

(c) Measure the underdrive clutch pack clearance while applying and releasing compressed air (392 kPa, 4.0 kgf/cm2, 57 psi).

Pack clearance: 1.51 to 1.71 mm (0.0594 to 0.0673 in.)

If the pack clearance is not as specified, inspect the discs, plates and flange.

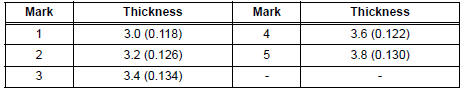

HINT: There are 5 flanges in different thickness.

Flange thickness: mm (in.)

2. INSPECT UNDERDRIVE CLUTCH DISC NO.1

(a) Check if the sliding surface of the disc, plate and flange are worn or burnt. If necessary, replace them.

HINT:

- If the lining of the disc comes off or discolors, or if a part of the groove is worn, replace all discs.

- Before installing new discs, immerse them in ATF for at least 15 minutes.

3. INSPECT UNDERDRIVE CLUTCH DRUM SUBASSEMBLY

(a) Using a dial indicator, measure the inside diameter of the underdrive clutch drum bushing.

Standard drum bushing: 37.06 to 37.08 mm (1.4591 to 1.4598 in.) Maximum drum bushing: 37.13 mm (1.4618 in.)

If the inside diameter is greater than the maximum, replace the underdrive clutch drum.

4. INSPECT UNDERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY

(a) Using a vernier calipers, measure the free length of the spring together with the spring seat.

Standard free length: 17.14 mm (0.6752 in.)

Disassembly

Disassembly

1. INSPECT UNDERDRIVE PACK CLEARANCE

HINT:

(See page AX-262)

2. REMOVE UNDERDRIVE CLUTCH FLANGE NO.2 HOLE

SNAP RING

a) Using a screwdriver, remove the underdrive clutch

flange No.2 snap rin ...

Reassembly

Reassembly

1. INSTALL UNDERDRIVE CLUTCH DRUM O-RING

(a) Coat a new O-ring with ATF, and install it to the

underdrive clutch drum.

NOTICE:

Make sure that the O-ring is not twisted or

pinched.

2. INSTALL ...

Other materials:

Disc cannot be Played/ No Playable Files/ Copyright Protection Error/ Disc

cannot be Played/ No Playable Files/ Copyright Protection Error

DTC 62-7D Disc cannot be Played

DTC 62-7E No Playable Files

DTC 62-7F Copyright Protection Error

DTC 63-7D Disc cannot be Played

DTC 63-7E No Playable Files

DTC 63-7F Copyright Protection Error

DESCRIPTION

INSPECTION PROCEDURE

HINT:

After the inspection is completed, clear the DTCs.

1 ...

Installation

1. INSTALL PARK/NEUTRAL POSITION SWITCH ASSEMBLY

(a) Install the park/neutral position switch to the manual

valve shaft.

(b) Temporarily install the 2 bolts.

(c) Place a new lock plate and tighten the nut.

Torque: 6.9 N*m (70 kgf*cm, 61 in.*lbf)

(d) Temporarily install the control ...

Camshaft Position "A" Actuator Circuit

DTC P0010 Camshaft Position "A" Actuator Circuit (Bank

1)

DTC P0020 Camshaft Position "A" Actuator Circuit (Bank

2)

DESCRIPTION

The Variable Valve Timing (VVT) system includes the ECM, Oil Control Valve (OCV)

and VVT controller.

The ECM sends a target duty-cycle control ...