Toyota Sienna Service Manual: Installation

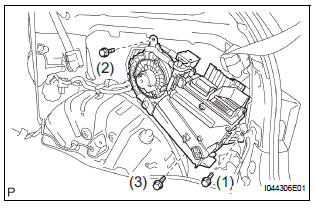

1. INSTALL AIR CONDITIONING BLOWER ASSEMBLY

(a) Install the air conditioning blower assembly with the 3 bolts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

NOTICE: Tighten the bolts in the order shown in the illustration to install the air conditioning blower assembly.

2. INSTALL AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY

(a) Sufficiently apply compressor oil to 2 new O-rings and the fitting surface of the air conditioning tube & accessory assembly.

Compressor oil: ND-OIL 8 or equivalent

(b) Install the 2 O-rings on the air conditioning tube & accessory assembly.

(c) Install the air conditioning tube & accessory assembly with the 2 bolts.

Torque: 3.5 N*m (36 kgf*cm, 31 in.*lbf)

3. ADD ENGINE COOLANT

HINT: See page CO-7.

4. CHARGE REFRIGERANT

SST 07110-58060 (07117-58060, 07117-58070, 07117-58080, 07117-58090, 07117-78050, 07117-88060, 07117-88070, 07117-88080)

HINT: See page AC-172.

5. WARM UP ENGINE

6. INSPECT FOR ENGINE COOLANT LEAK

HINT: See page CO-1.

7. INSPECT REFRIGERANT LEAK

HINT: See page AC-168.

Reassembly

Reassembly

1. INSTALL HEATER RADIATOR UNIT SUB-ASSEMBLY

(a) Install the heater radiator unit sub-assembly to the

air conditioning blower assembly.

(b) Install the 2 O-rings to the heater water valve

as ...

Blower motor

Blower motor

On-vehicle inspection

1. INSPECT BLOWER WITH FAN MOTOR SUBASSEMBLY

(a) Connect the positive (+) lead from the battery to

terminal 2 and negative (-) to terminal 1, then check

that the motor op ...

Other materials:

ACIS Control Circuit

DESCRIPTION

This circuit opens and closes the Intake Air Control Valve (IACV) in response

to changes in the engine

load in order to increase the intake efficiency (ACIS: Acoustic Control

Induction System).

When the engine speed is between 0 and 4450 rpm and the throttle valve opening

angl ...

Laser Sensor Power Source Circuit

DESCRIPTION

This circuit provides power to the laser sensor. The laser sensor emits radio

waves towards an object in

front and measures the distance and direction of the object by receiving the

beam reflections. Based on

the reflections, the sensor calculates the difference in speed between t ...

Front wiper rubber

COMPONENTS

REMOVAL

1. REMOVE FRONT WIPER BLADE

Remove the front wiper blade from the front wiper

arm LH.

NOTICE:

Do not fold down the front wiper arm with the

front wiper blade being removed from it.

2. REMOVE FRONT WIPER RUBBER

Remove the front wiper rubber from th ...