Toyota Sienna Service Manual: Installation

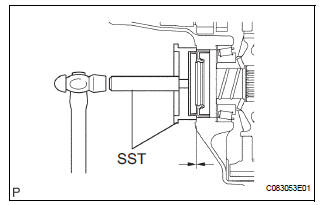

1. INSTALL TRANSAXLE HOUSING OIL SEAL

(a) Using SST and a hammer, install a new oil seal.

SST 09316-60011 (09316-00011) Oil seal installation depth: -0.5 to 0.5 mm (-0.020 to 0.020 in.) (b) Coat the lip of the oil seal with MP grease.

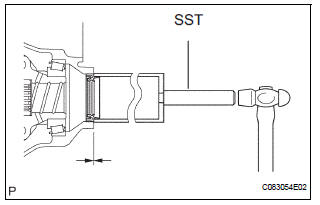

2. INSTALL DIFFERENTIAL SIDE BEARING RETAINER OIL SEAL

(a) Using SST and a hammer, install a new oil seal.

SST 09223-15020, 09950-70010 (09951-07150) Oil seal installation depth: -0.5 to 0.5 mm (-0.020 to 0.020 in.) (b) Coat the lip of the oil seal with MP grease.

3. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

HINT: (See page DS-17)

4. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH (for 2WD)

HINT: (See page DS-17)

5. INSTALL FRONT WHEELS Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf) 6. ADD AUTOMATIC TRANSAXLE FLUID 7. INSPECT AUTOMATIC TRANSAXLE FLUID (See page AX-123) 8. INSTALL ENGINE UNDER COVER NO.1 9. CHECK ABS SPEED SENSOR SIGNAL

HINT: (See page BC-82)

Removal

Removal

1. REMOVE FRONT WHEELS

2. REMOVE ENGINE UNDER COVER NO.1

3. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the drain plug, gasket and drain ATF.

(b) Install a new gasket and the drain plug.

Torqu ...

Automatic transaxle assembly

Automatic transaxle assembly

Components

...

Other materials:

Rear Blower Motor Circuit

DESCRIPTION

Power to the rear blower motor is supplied from the battery via the RR A/C

relay.

The rear blower motor speed level varies between 0 and 31 based on the voltage

difference measured

between the terminals of the motor.

The voltage difference measured between the terminals of th ...

Mass or Volume Air Flow Circuit Range / Performance Problem

DESCRIPTION

Refer to DTC P0100 (See page ES-116).

MONITOR DESCRIPTION

The MAF meter is a sensor that measures the amount of air flowing through the

throttle valve. The ECM

uses this information to determine the fuel injection time and to provide an

appropriate air-fuel ratio.

Insi ...

Reverse Signal Circuit

DESCRIPTION

The radio and navigation assembly receives a reverse signal from the

park/neutral position switch.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 INSPECT RADIO AND NAVIGATION ASSEMBLY

Disconnect the radio and navigation assembly connector

R12.

Measure the voltage accor ...