Toyota Sienna Service Manual: Monitor drive pattern

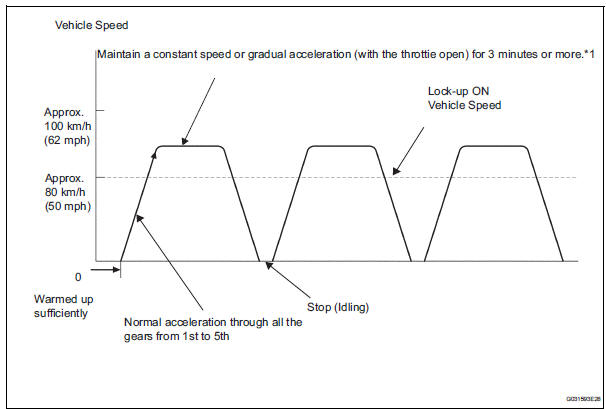

1. MONITOR DRIVE PATTERN FOR ECT TEST

(a) Perform this drive pattern as one method to simulate the detection conditions of the ECT malfunctions. (The DTCs may not be detected due the actual driving conditions. And some codes may not be detected through this drive pattern.)

HINT: Preparation for driving

- Warm up the engine sufficiently. (Engine coolant temperature is 60°C (140°F) or higher)

- Drive the vehicle when the atmospheric

temperature is -10°C (14°F) or higher.

(Malfunction is not detected when the atmospheric temperature is less than -10°C (14°F))

Driving note

- Drive the vehicle through all gears.

Stop → 1st → 2nd → 3rd → 4th → 5th → 5th (lock-up ON).

- Repeat the above driving pattern three times or more.

NOTICE:

|

HINT: *1: Drive at such a speed in the uppermost gear, to engage lock-up. The vehicle can be driven at a speed lower than that in the above diagram under the lock-up condition.

| NOTICE: If necessary to drive the vehicle for approximately 30 minutes to detect DTC P0711 (ATF temperature sensor malfunction). |

Initialization

Initialization

1. RESET MEMORY

NOTICE:

Perform the RESET MEMORY (AT initialization)

when replacing the automatic transaxle assembly,

engine assembly or ECM.

The RESET MEMORY can be performed ...

Problem symptoms table

Problem symptoms table

HINT:

If a normal code is displayed during the diagnostic trouble

code check although the trouble still occurs, check the

electrical circuits for each symptom in the order given in

the chart ...

Other materials:

Air fuel ratio sensor relay

INSPECTION

1. INSPECT AIR FUEL RATIO SENSOR RELAY

Using an ohmmeter, measure the resistance

according to the value(s) in the table below.

Standard resistance

If the result is not as specified, replace the relay. ...

Only Wireless Door Lock Control Function does not Operate

DESCRIPTION

The door control receiver receives a signal from the transmitter and sends

this signal to the multiplex

network body ECU. Then, the multiplex network body ECU controls operation of the

door locks and power

windows.

Then, the power slide door ECU causes the power slide door to o ...

Rear Clearance Sonar Sensor RH Circuit

DESCRIPTION

An ultrasonic sensor consists of a sensor portion that transmits and receives

ultrasonic waves and a preamplifier

that amplifies them. The ultrasonic sensor outputs the ultrasonic waves and

sends the received

signals to the clearance warning ECU.

WIRING DIAGRAM

INSPECTION PR ...