Toyota Sienna Service Manual: Reassembly

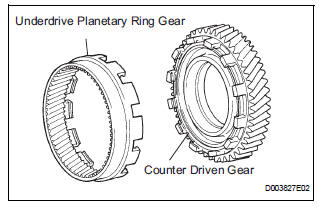

1. INSTALL UNDERDRIVE PLANETARY RING GEAR

HINT: Use a torque wrench with a fulcrum length of 160 mm (6.3 in.).

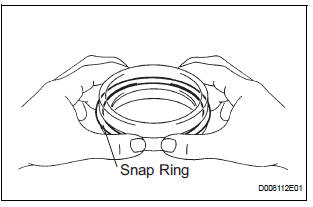

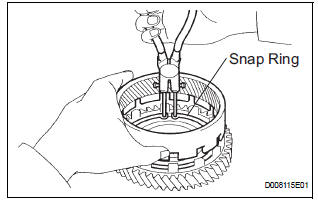

(a) Install a new snap ring to the outer race of the radial ball bearing rear.

HINT: When replacing the bearing, also replace the counter driven gear with a new one.

(b) Using a piston ring compressor, squeeze the snap ring.

(c) Using SST and a press, press in the outer race of the radial ball bearing rear.

SST 09950-60020 (09951-00890), 09950-70010 (09951-07100)

NOTICE: Be sure not to damage the snap ring during outer race installation.

(d) Install the underdrive planetary ring gear to the counter driven gear.

(e) Using a snap ring pliers, install the snap ring.

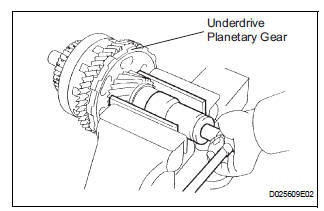

2. INSTALL UNDERDRIVE PLANETARY GEAR ASSEMBLY

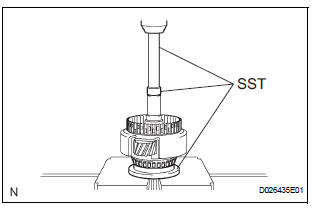

(a) Using SST and a press, press the radial ball bearing rear in the underdrive planetary gear.

SST 09502-12010, 09950-60010 (09951-00260), 09950-70010 (09951-07100)

NOTICE: Press the bearing until it becomes flat at the bottom.

(b) Install the counter driven gear with planetary ring gear to the underdrive planetary gear.

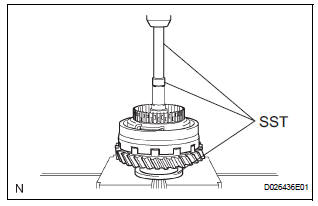

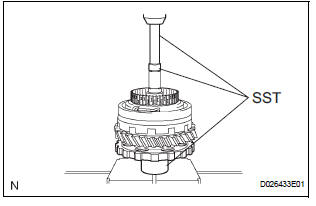

(c) Using SST and a press, press in the radial ball bearing front.

SST 09502-12010, 09950-60010 (09951-00260), 09950-70010 (09951-07100)

NOTICE: Press the counter driven gear while rotating it.

(d) Using SST and a press, press in the parking lock gear.

SST 09502-12010, 09950-60010 (09951-00260), 09950-70010 (09951-07100)

NOTICE: Press the counter driven gear while rotating it.

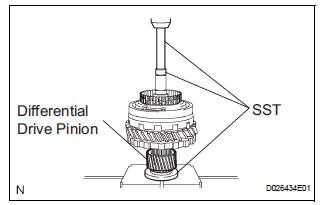

3. INSTALL DIFFERENTIAL DRIVE PINION

(a) Using SST and a press, press the differential drive pinion.

SST 09726-40010, 09950-60010 (09951-00260), 09950-70010 (09951-07100)

NOTICE: Press the counter driven gear while rotating it

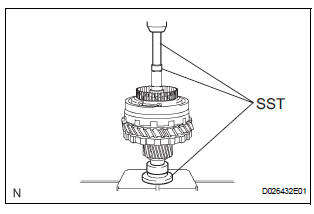

4. INSTALL CYLINDRICAL ROLLER BEARING RACE INNER

(a) Using SST and a press, press the cylindrical roller bearing race inner.

SST 09506-35010, 09950-60010 (09951-00260), 09950-70010 (09951-07100)

NOTICE: Press the counter driven gear while rotating it.

5. INSTALL FRONT PLANETARY GEAR NUT

(a) Place the underdrive planetary gear in a soft jaw vise.

NOTICE: Be careful not to damage the differential drive pinion.

(b) Using a socket wrench, install a new lock nut.

Torque: 280 N*m (2,885 kgf*cm, 207 ft.*lbf)

HINT: Use a torque wrench with a fulcrum length of 750 mm (29.53 in.).

(c) Using a pin punch and hammer, stake the lock nut.

CAUTION: Be sure that there are no cracks on the nut.

6. INSPECT UNDERDRIVE PLANETARY GEAR PRELOAD

HINT: (See page AX-260)

Inspection

Inspection

1. INSPECT UNDERDRIVE PLANETARY GEAR PRELOAD

(a) Using SST, fix the underdrive planetary gear

assembly.

SST 09387-00050

(b) Using SST and a torque wrench, measure the

turning torque of th ...

Other materials:

TC and CG Terminal Circuit

DESCRIPTION

Connecting terminals TC and CG of the DLC3 causes the system to enter the

self-diagnostic mode. If a

malfunction is present, DTCs will be output.

HINT:

When a particular warning light remains blinking, a ground short in the wiring

of terminal TC of the DLC3

or an internal ground ...

Installation

1. INSTALL REAR COIL SPRING INSULATOR UPPER LH

(a) Install the insulator upper LH to the coil spring rear

LH.

2. INSTALL COIL SPRING REAR LH

(a) Apply a shop rug to the rear axle beam assembly.

(b) Install the coil spring rear LH to the rear axle beam

assembly.

HINT:

Fit the lowe ...

Installation

HINT:

Install the RH side by the same procedures with LH side.

1. INSTALL FRONT SPEED SENSOR LH

(a) Install the speed sensor front LH with the bolt.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

NOTICE:

Keep the tip of the front speed sensor LH.

(b) Install the sensor harness clamps with th ...