Toyota Sienna Service Manual: Inspection

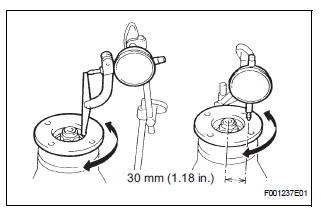

1. INSPECT RUNOUT OF DIFFERENTIAL RING GEAR

(a) Using a dial gauge , check the runout of the ring gear.

Maximum runout: 0.07 mm (0.0028 in.)

If the runout is greater than the maximum, replace the ring gear with a new one.

2. INSPECT DIFFERENTIAL RING GEAR BACKLASH

(a) Using a dial gauge, check the backlash of the ring gear.

Backlash: 0.13 to 0.18 mm (0.0051 to 0.0071 in.)

If the backlash is not within the specification, adjust the side bearing preload or repair as necessary.

3. INSPECT RUNOUT OF REAR DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY

(a) Using a dial gauge, measure the runout of the companion flange vertically and horizontally.

Maximum runout: 0.10 mm (0.0039 in.)

Disassembly

Disassembly

1. REMOVE REAR DIFFERENTIAL CARRIER COVER

(a) Remove the 8 bolts from the carrier cover.

(b) Using a brass bar and a hammer, separate the

carrier cover from rear differential carrier assembly ...

Reassembly

Reassembly

1. INSTALL REAR DIFFERENTIAL PINION SHAFT

(a) Install the 2 thrust washers to the 2 side gears.

(b) Install the 2 side gears, 2 differential pinion gears, 2

differential pinion thrust washers ...

Other materials:

Front Occupant Classification Sensor RH Circuit

Malfunction

DTC B1781 Front Occupant Classification Sensor RH Circuit

Malfunction

DESCRIPTION

The front occupant classification sensor RH circuit consists of the occupant

classification ECU and the

front occupant classification sensor RH.

DTC B1781 is recorded when a malfunction is detected in the fron ...

Manual shifting test

1. Perform manual shifting test

Hint:

With this test, it can be determined whether the

trouble occurs in the electrical circuit or is a

mechanical problem in the transaxle.

If any abnormalities are found in the following test, the

problem is in the transaxle itself.

(A) disconnec ...

Brake Switch "B" Circuit High

DESCRIPTION

The purpose of this circuit is to prevent the engine from stalling while

driving in lock-up condition when

brakes are suddenly applied.

When the brake pedal is depressed, this switch sends a signals to the ECM. Then

the ECM cancels the

operation of the lock-up clutch while ...