Toyota Sienna Service Manual: Engine front oil seal

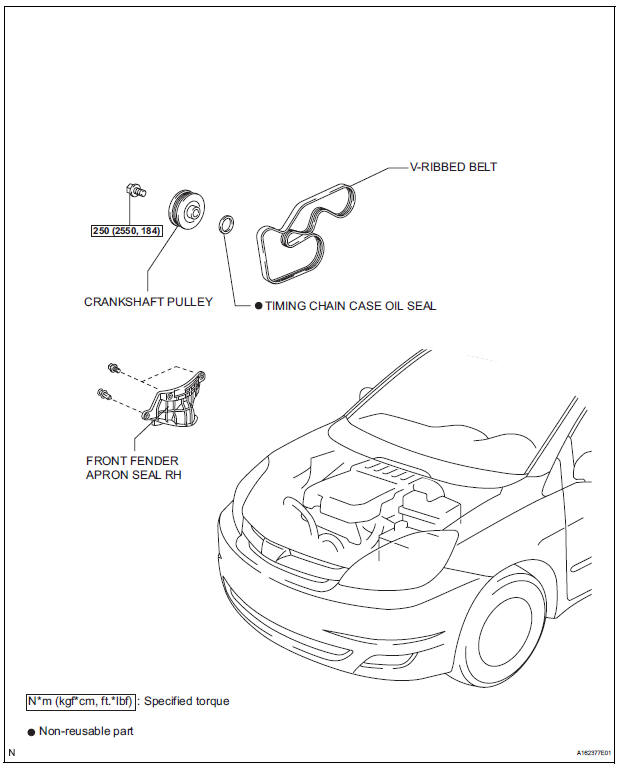

COMPONENTS

REMOVAL

1. REMOVE FRONT WHEEL RH 2. REMOVE FRONT FENDER APRON SEAL RH (See page EM-26) 3. REMOVE V-RIBBED BELT (See page EM-6) 4. REMOVE CRANKSHAFT PULLEY

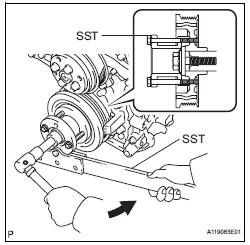

(a) Using SST, loosen the crankshaft pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021

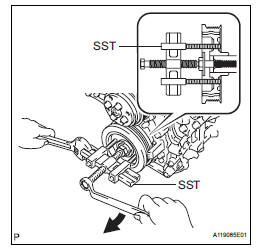

(b) Using SST, remove the crankshaft pulley bolt and crankshaft pulley.

SST 09950-50013 (09951-05010, 09952-05010, 09953-05020, 09954-05021)

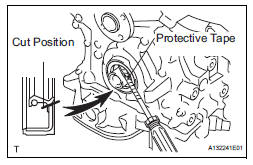

5. REMOVE TIMING CHAIN CASE OIL SEAL

(a) Using a screwdriver, pry out the oil seal.

HINT:

Tape the screwdriver tip before use.

| NOTICE: After the removal, check the crankshaft for damage. If it is damaged, smooth the surface with 400-grit sandpaper. |

INSTALLATION

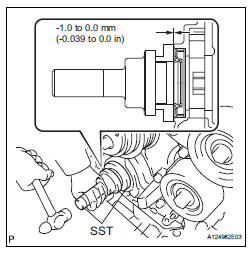

1. INSTALL TIMING CHAIN CASE OIL SEAL

(a) Apply MP grease to a new oil seal lip.

(b) Using SST and a hammer, tap in the oil seal until its surface is flush with the timing chain cover edge.

SST 09223-22010, 09506-35010

NOTICE:

|

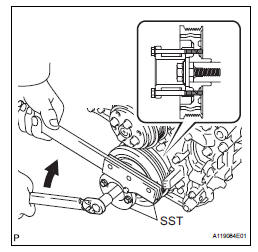

2. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the pulley, and slide on the pulley.

(b) Using SST, install the pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021 Torque: 250 N*m (2550 kgf*cm, 184 ft.*lbf)

3. INSTALL V-RIBBED BELT (See page EM-7) 4. INSTALL FRONT FENDER APRON SEAL RH (See page EM-62) 5. INSTALL FRONT WHEEL RH Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

Drive belt

Drive belt

COMPONENTS

REMOVAL

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

3. REMOVE V-RIBBED BELT

(a) Using SST, release the belt tension by turning the

belt tensi ...

Engine rear oil seal

Engine rear oil seal

Components

Removal

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for

2WD)

HINT:

See page AX-163.

2. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for

4WD)

HINT:

See page AX-167.

3. REMOVE DRIVE PLATE A ...

Other materials:

A/F sensor and ho2s monitors

(a) Preconditions

The monitor will not run unless:

2 minutes or more have elapsed since the engine

was started.

The Engine Coolant Temperature (ECT) is 75°C

(167°F) or more.

Cumulative driving time at a vehicle speed of 30

mph (48 km/h) or more exceeds 6 minutes.

Air-fuel ratio fe ...

Illumination Circuit

DESCRIPTION

Power is supplied to the radio and navigation assembly and steering pad

switch illumination when the

light control switch is in the TAIL or HEAD position.

WIRING DIAGRAM

INSPECTION PROCEDURE

NOTICE:

The vehicle is equipped with an SRS (Supplemental Restraint System) such as t ...

Compressor Solenoid Circuit

DESCRIPTION

In this circuit, the compressor receives a refrigerant compression demand

signal from the A/C amplifier.

Based on this signal, the compressor changes the amount of compressor output.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 INSPECT A/C COMPRESSOR

(a) Disconnect the A/C com ...