Toyota Sienna Service Manual: Inspection

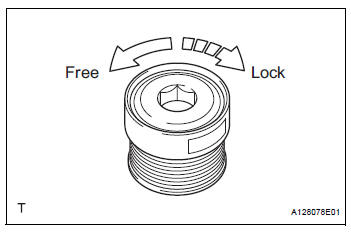

1. Inspect generator clutch pulley

(a) Hold the center of the pulley, and confirm that the outer ring turns counterclockwise and does not turn clockwise.

If the result is not as specified, replace the clutch pulley.

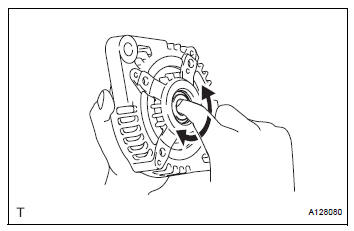

2. Remove generator drive end frame bearing

(a) Check that the bearing is not rough or worn.V

Ok: the bearing rotates smoothly.

If the bearing does not rotate smoothly, replace the bearing.

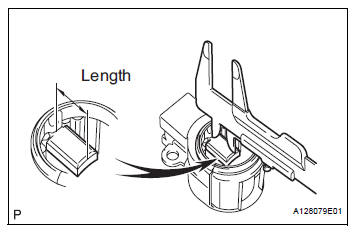

3. Inspect generator brush holder assembly

(a) Using vernier calipers, measure the length of the exposed brushes.

Standard exposed length: 9.5 to 11.5 mm (0.374 to 0.453 in.) Minimum exposed length: 4.5 mm (0.177 in.) If the exposed length is less than the minimum, replace the brush holder assembly.

4. INSPECT GENERATOR ROTOR ASSEMBLY

(a) Check that the generator rotor bearing is not rough or worn.

If necessary, replace the generator rotor assembly.

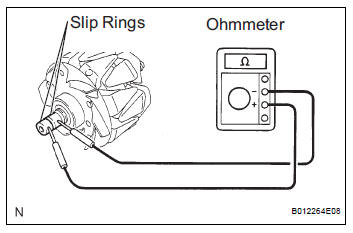

(b) Check the generator rotor for an open circuit.

(1) Using an ohmmeter, measure the resistance between the slip rings.

Standard resistance

If the result is not as specified, replace the generator rotor assembly.

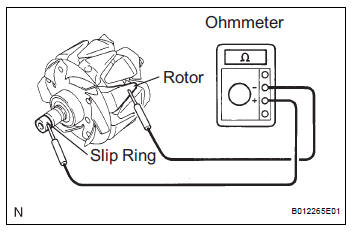

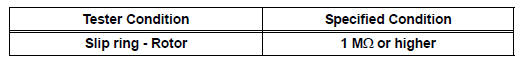

(c) Check the rotor for a short to ground.

(1) Using an ohmmeter, measure the resistance between the slip ring and rotor.

Standard resistance

If the result is not as specified, replace the generator rotor assembly.

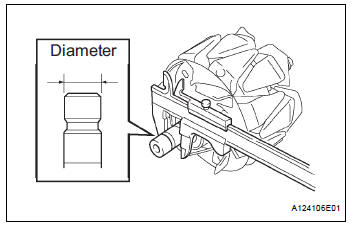

(d) Using vernier calipers, measure the slip ring diameter.

Standard diameter: 14.2 to 14.4 mm (0.559 to 0.567 in.) Minimum diameter: 14.0 mm (0.551 in.)

If the diameter is less than the minimum, replace the generator rotor assembly.

Disassembly

Disassembly

1. REMOVE GENERATOR CLUTCH PULLEY

(A) using a screwdriver, remove the generator pulley

cap.

(b) Set SST (A) and (B).

SST 09820-63020

(c) Clamp SST (A) in a vise.

NOTICE:

...

Replacement

Replacement

1. REPLACE GENERATOR DRIVE END FRAME BEARING

(a) Remove the 4 screws and retainer plate from the

drive end frame.

(b) Using SST and a hammer, tap out the drive end

frame bearing from the d ...

Other materials:

Adjustment

HINT:

On the RH side, use the same procedures as on the LH

side.

Since a centering bolt is used as door hinge mounting

bolts on the body side and the door side, the door cannot

be adjusted with them on. Substitute a bolt with a washer

for the centering bolt.

1. INSPECT BACK DOOR PAN ...

Installation

1. INSTALL BRAKE ACTUATOR

NOTICE:

Do not remove the hole plugs before connecting the

brake tubes. New actuators are filled with brake

fluid.

(a) Install the brake actuator assembly with the 2 nuts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

2. INSTALL BRAKE ACTUATOR WITH BRACKET

(a) Insta ...

Installation

1. Install speed sensor (nc sensor)

(a) Coat the O-ring with ATF.

(b) Install the speed sensor with the bolt.

Torque: 11 N*m (115 kgf*cm, 8 ft.*lbf)

HINT:

Make sure to install the same manufacturer's

sensor.

(c) Connect the speed sensor connector.

2. INSTALL SPEED SENSOR (NT SENSOR)

...