Toyota Sienna Service Manual: Differential system

PRECAUTION

NOTICE:

When disconnecting the negative (-) battery terminal, initialize the following systems after the terminal is reconnected.

1. Before disassembly, clean the outside of the rear differential assembly and remove any sand or mud to prevent it from entering the inside of the assembly during disassembly and reassembly.

2. When removing a connected part made of light alloy such as a rear differential carrier cover, tap it off with a plastic hammer. Do not attempt to pry it off with a screwdriver.

3. Always arrange disassembled parts in order and protect them from dust.

4. Before reassembly, thoroughly clean and dry each part or then apply hypoid gear oil LSD to it. Do not use alkaline cleaner for aluminum or rubber parts and ring gear set bolts. Also, do not clean rubber parts such as O-rings or oil seals with non residue solvent.

5. Coat any sliding surface and rotating part with hypoid gear oil LSD.

6. When holding a component part in a vise, be sure to place an aluminum sheet under the part. Do not put it directly on the vise.

7. Be careful not to damage the contact surfaces of the case. Such damage may cause oil leakage.

8. Before applying sealant, remove deposited oil sealant and clean the part to be sealed using non residue solvent.

9. Do not apply oil immediately after installing sealed parts. Leave it for at least an hour.

10.Damage on the surface of an oil seal, O-ring or gasket may cause oil leakage.

11.When press-fitting an oil seal, be careful not to damage the oil seal lip and outside periphery.

12.When replacing a bearing, replace the inner and outer races as a set.

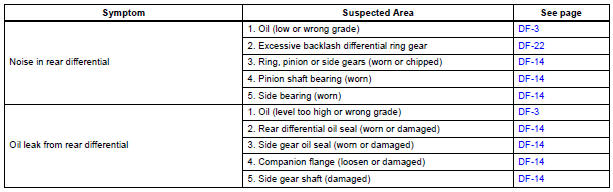

PROBLEM SYMPTOMS TABLE

HINT: Use the table below to help you find the cause of the problem.

The numbers indicate the priority of the likely cause of the problem. Check each part in order. If necessary, replace these parts.

DIFFERENTIAL SYSTEM:

Differential

Differential

...

Differential oil

Differential oil

Adjustment

1. INSPECT DIFFERENTIAL OIL

(a) Stop the vehicle on the level place.

(b) Remove the differential filler plug and gasket.

(c) Check that the oil surface is within 5 mm (0.20 in.) ...

Other materials:

Crankshaft Position Sensor "A" Circuit

DTC P0335 Crankshaft Position Sensor "A" Circuit

DTC P0339 Crankshaft Position Sensor "A" Circuit Intermittent

DESCRIPTION

The Crankshaft Position (CKP) sensor system consists of a CKP sensor plate

and a pickup coil. The

sensor plate has 34 teeth and is installed on the cra ...

Folding and extending the mirrors

Manual type

Push the mirror back in the direction

of the vehicleâs rear.

Power type

Press the switch.

Folding

Extending

...

Registering a BluetoothÂź

audio player for the

first time

To use the BluetoothÂź Audio, it is necessary to register an audio

player with the system.

Once the player has been registered, it is possible to use the

BluetoothÂź Audio.

For details about registering a BluetoothÂź device

Turn the BluetoothÂź connection setting of your audio player on ...