Toyota Sienna Service Manual: Disassembly

1. REMOVE LOWER BALL JOINT ASSEMBLY FRONT LH

(a) Remove the cotter pin and nut.

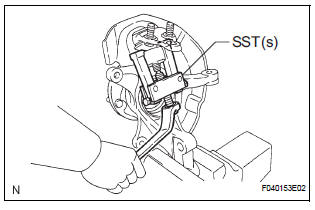

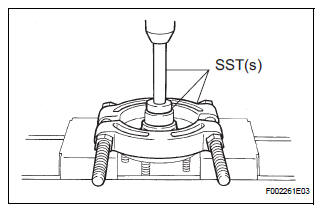

(b) Using SST(s), remove the lower ball joint assembly front LH.

SST 09628-62011

2. REMOVE FRONT WHEEL BEARING DUST DEFLECTOR NO.1 LH

(a) Using a screwdriver, remove the bearing dust deflector NO. 1 LH.

3. REMOVE FRONT AXLE HUB LH HOLE SNAP RING

(a) Using snap ring pliers, remove the front axle hub LH hole snap ring.

4. REMOVE FRONT AXLE ASSEMBLY LH

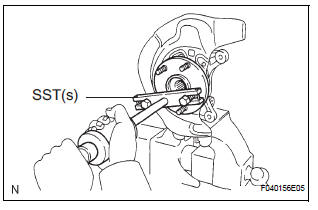

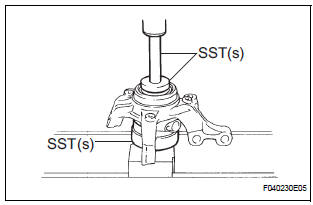

(a) Using SST(s), remove the front axle hub subassembly LH.

SST 09520-00031

(b) Using SST(s) and a press, remove the bearing inner race (outside) from the front axle hub sub-assembly LH.

SST 09950-00020, 09950-60010 (09951-00430), 09950-70010 (09951-07100)

5. REMOVE DISC BRAKE DUST COVER FRONT LH

(a) Using a torx wrench (T30), remove the 4 bolts and disc brake dust cover front LH.

HINT: Torx is a registered trademark of Textron Inc.

6. REMOVE FRONT AXLE HUB LH BEARING

(a) Place the bearing inner race (outside) on the front axle hub LH bearing.

(b) Using SST(s) and a press, press the front axle hub LH bearing until it contacts the SST(s).

SST 09527-17011, 09950-60010 (09951-00600), 09950-70010 (09951-07100)

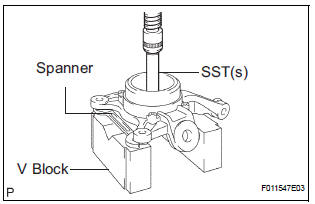

(c) Using a spanner to make the steering knuckle LH horizontal, fix it to the V block, as shown in the illustration.

NOTICE: Be sure the steering knuckle is horizontally positioned.

(d) Using SST(s) and a press, remove the front axle hub LH bearing.

SST 09950-60010 (09951-00600), 09950-70010 (09951-07100)

Removal

Removal

HINT:

Replace the RH side using the same procedures as for the

LH side.

1. REMOVE FRONT WHEEL

2. REMOVE FRONT AXLE HUB LH NUT (See page DS-

5)

3. SEPARATE SPEED SENSOR FRONT LH (See page

DS-5)

...

Reassembly

Reassembly

1. INSTALL FRONT AXLE HUB LH BEARING

(a) Using SST(s) and a press, install a new front axle

hub LH bearing to the steering knuckle LH.

SST 09950-60020 (09951-00810), 09950-70010

(09951-07100 ...

Other materials:

Removal

1. DRAIN BRAKE FLUID

NOTICE:

Wash brake fluid off immediately if it adheres to any

painted surface.

2. DISCONNECT BATTERY NEGATIVE TERMINAL

3. REMOVE AIR CLEANER ASSEMBLY WITH HOSE

4. REMOVE BRAKE ACTUATOR WITH BRACKET

(a) Release the latch of the brake actuator connector to

disconnect t ...

No. 1 Ultrasonic sensor

COMPONENTS

REMOVAL

1. REMOVE FRONT FENDER LINER LH

2. REMOVE FRONT FENDER LINER RH

3. REMOVE FRONT BUMPER COVER

4. REMOVE REAR BUMPER COVER (2)

5. REMOVE NO. 1 ULTRASONIC SENSOR RETAINER

Remove the No. 1 ultrasonic sensor retainer as

shown in the illustration

6. REMOVE ...

Window defogger switch

INSPECTION

1. INSPECT WINDOW DEFOGGER SWITCH

Check the defogger switch illuminates.

Standard

If the result is not as specified, replace the switch

assembly or bulb.

Check the defogger timer.

Connect the positive (+) lead from the battery

to terminal 2 and ...