Toyota Sienna Service Manual: Reassembly

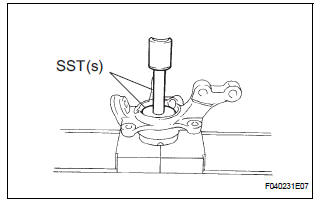

1. INSTALL FRONT AXLE HUB LH BEARING

(a) Using SST(s) and a press, install a new front axle hub LH bearing to the steering knuckle LH.

SST 09950-60020 (09951-00810), 09950-70010 (09951-07100)

2. INSTALL DISC BRAKE DUST COVER FRONT LH

(a) Place the disc brake dust cover front LH and using a torx wrench (T30), torque the 4 bolts.

Torque: 8.3 N*m (85 kgf*cm, 74 in.*lbf)

HINT: Torx is a registered trademark of Textron Inc.

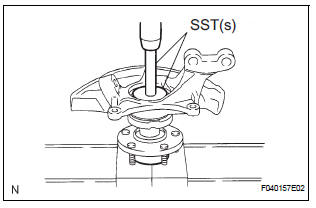

3. INSTALL FRONT AXLE HUB SUB-ASSEMBLY LH

(a) Using SST(s), and a press, install the front axle hub sub-assembly LH.

SST 09608-32010, 09950-60020 (09951-00810), 09950-70010 (09951-07100)

4. INSTALL FRONT AXLE HUB LH HOLE SNAP RING

(a) Using snap ring pliers, install a new front axle hub LH hole snap ring.

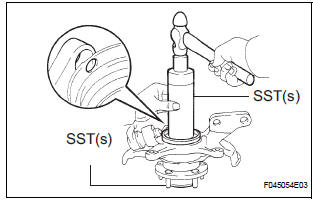

5. INSTALL FRONT WHEEL BEARING DUST DEFLECTOR NO.1 LH

(a) Using SST(s) and a hammer, install the bearing dust deflector No. 1 LH.

SST 09316-60011 (09316-00011, 09316-00031), 09608-32010

HINT: Align the hole for the speed sensor in the bearing dust deflector No. 1 LH with the steering knuckle.

6. INSTALL LOWER BALL JOINT ASSEMBLY FRONT LH

(a) Install the lower ball joint assembly front LH and tighten the nut.

Torque: 123 N*m (1,250 kgf*cm, 91 ft.*lbf) (b) Install a new cotter pin.

NOTICE: If the holes for the cotter pin are not aligned, tighten the nut up to 60° further.

Disassembly

Disassembly

1. REMOVE LOWER BALL JOINT ASSEMBLY FRONT LH

(a) Remove the cotter pin and nut.

(b) Using SST(s), remove the lower ball joint assembly

front LH.

SST 09628-62011

2. REMOVE FRONT WHEEL BEAR ...

Installation

Installation

1. INSTALL FRONT AXLE ASSEMBLY LH

(a) Install the 2 bolts, nuts and front axle assembly LH

with the 2 bolts and nuts to the shock absorber

assembly front LH.

Torque: 230 N*m (2,350 kgf*cm, 170 ...

Other materials:

Installation

1. INSTALL PARKING BRAKE CONTROL PEDAL ASSEMBLY

(a) Install the parking brake control pedal assembly with

a bolt and the 2 nuts.

Torque: 39 N*m (398 kgf*cm, 29 ft.*lbf)

(b) Connect the parking brake switch connector.

(c) Connect the instrument panel junction block

assembly w/ wiring ha ...

Parking brake

Operating instructions

To set the parking brake, fully

depress the parking brake pedal

with your left foot while depressing

the brake pedal with your right

foot.

(Depressing the pedal again

releases the parking brake.)

Usage in winter time

NOTICEBefore driving

Fully release ...

Occupant Classification ECU Malfunction

DTC B1795 Occupant Classification ECU Malfunction

DESCRIPTION

DTC B1795 is recorded when a malfunction is detected in the occupant

classification ECU.

Troubleshoot DTC B1771 first when the DTCs B1771 and B1795 are output

simultaneously.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK DTC ...