Toyota Sienna Service Manual: Inspection

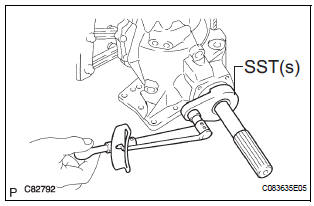

1. INSPECT PRELOAD

(a) Using SST(s) and a torque wrench, check the initial torque within the backlash range.

SST 09326-20011 Torque: 0.9 to 1.4 N*m (9 to 14 kgf*cm, 8.0 to 12.4 in.*lbf)

HINT: Use a torque wrench with a fulcrum length of 160 mm (6.30 in.).

(b) Using SST(s) and a torque wrench, check the initial torque while the driven pinion is in contact with the ring gear face.

SST 09326-20011 Torque: Preload +0.15 to 0.30 N*m (+1.6 to 3.1 kgf*cm, +1.3 to 2.7 in.*lbf)

HINT: Use a torque wrench with a fulcrum length of 160 mm (6.30 in.).

2. INSPECT DIFFERENTIAL RING GEAR BACKLASH

(a) Set the dial gauge perpendicular to the tooth face of the ring gear, fix the driven pinion and inspect the backlash while moving the gear.

Backlash: 0.10 to 0.15 mm (0.0039 to 0.0059 in.)

NOTICE: Inspect it at 3 points or more on the gear's periphery.

3. INSPECT TOOTH CONTACT BETWEEN RING GEAR AND DRIVE PINION

(a) Apply red lead primer thinly and uniformly to both faces of the ring gear and rotate several times.

NOTICE: Inspect the tooth contact on the ring gear at 4 places or more.

4. INSPECT RUNOUT OF TRANSFER RING GEAR MOUNTING CASE

(a) Using a dial gauge check the transfer ring gear mounting case runout.

Maximum runout: 0.03 mm (0.0012 in.)

Disassembly

Disassembly

1. REMOVE TRANSFER COVER GASKET

(a) Remove the transfer gasket from the transfer

assembly.

2. REMOVE TRANSFER CASE BREATHER PLUG

(a) Using a screwdriver and a hammer, remove the

transfer ...

Reassembly

Reassembly

1. INSTALL TRANSFER DRIVEN PINION REAR BEARING

(a) Using SST(s) and a press, install the transfer driven

pinion rear bearing outer race to the transfer case.

SST 09950-60010 (09951-00620), 09950-70 ...

Other materials:

Stop light switch

ON-VEHICLE INSPECTION

1. STOP LIGHT SWITCH ASSEMBLY

Check the resistance between the terminals at each

switch position as shown ion the chart.

Resistance

...

On-vehicle inspection

1. INSPECT REAR AXLE HUB BEARING BACKLASH

(a) Using a dial gauge, check for backlash near the

center of the axle hub.

Maximum:

0.05 mm (0.0020 in.)

If backlash exceeds the maximum, replace the axle

hub assembly.

NOTICE:

Ensure that the dial gauge is set at right angles

to the measuremen ...

How to proceed with

troubleshooting

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS

Interview the customer and confirm the trouble.

Confirm the problem by duplicating the conditions

described by the customer

3 BASIC INSPECTION

Basic inspection.

Measure the battery voltage.

Standard voltage:

11 ...