Toyota Sienna Service Manual: Reassembly

1. APPLY HIGH TEMPERATURE GREASE

(a) Apply the high temperature grease to the surface on which the shoe and backing plate attach.

2. INSTALL PARKING BRAKE SHOE LEVER LH

(a) Install the shoe lever and shim to the rear shoe with a new C-washer.

(b) Using a feeler gauge, measure the clearance.

Standard clearance: Less than 0.35 mm (0.0138 in.)

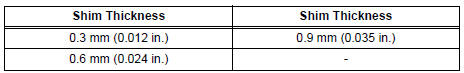

If the clearance is not within the specification,

replace the shim with one of the correct size.

(c) Install the correct side shim with a new C-washer.

(d) Remeasure the clearance.

3. INSTALL PARKING BRAKE SHOE ASSEMBLY LH NO.2

(a) Using needle-nose pliers, connect the parking brake cable No. 3 to the parking brake shoe lever.

(b) Install the parking brake shoe assembly LH No. 2 with the shoe hold-down compression spring pin No. 2, shoe hold-down compression spring and 2 cups.

4. INSTALL PARKING BRAKE SHOE ADJUSTING SCREW SET

(a) Apply the high temperature grease to the adjusting bolt.

(b) Install the parking brake shoe adjusting screw set LH.

5. INSTALL PARKING BRAKE SHOE STRUT LH

6. INSTALL PARKING BRAKE SHOE ASSEMBLY LH NO.1

(a) Install the parking brake shoe assembly LH No. 1 with the shoe hold-down compression spring pin No. 1, shoe hold-down compression spring and 2 cups.

(b) Install the tension spring and 2 shoe return tension springs.

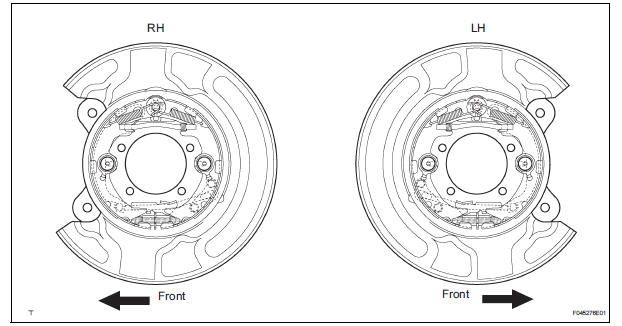

7. CHECK PARKING BRAKE INSTALLATION

(a) Check that each part is installed properly.

NOTICE: No oil or grease should be adhered to the friction surface of the shoe lining and disc.

8. INSTALL REAR DISC

9. ADJUST PARKING BRAKE SHOE CLEARANCE

(a) Temporarily install the hub nuts.

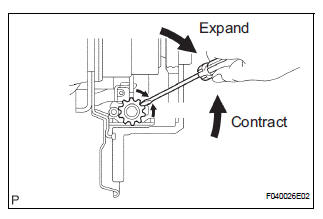

(b) Remove the hole plug, and turn the adjuster and expand the shoes until the disc locks.

(c) Contract the shoe adjuster until the disc can rotate smoothly.

Standard: Return 8 notches

(d) Check that the brake disc rotates smoothly.

(e) Install the hole plug.

10. CONNECT REAR DISC BRAKE CALIPER ASSEMBLY LH

11. INSTALL REAR WHEEL Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

12. INSPECT PARKING BRAKE PEDAL TRAVEL (See page PB-1)

13. ADJUST PARKING BRAKE PEDAL TRAVEL (See page PB-1)

Inspection

Inspection

1. INSPECT BRAKE DISC INSIDE DIAMETER

(a) Using a brake drum gauge or equivalent, measure

the inside diameter of the disc.

Standard inside diameter:

190 mm (7.480 in.)

Maximum inside diameter ...

Other materials:

Display Signal Circuit between Radio and Navigation Assembly and

Television Camera Assembly

DESCRIPTION

This is the display signal circuit of the television camera assembly.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK HARNESS AND CONNECTOR (RADIO AND NAVIGATION ASSEMBLY - TELEVISION

CAMERA ASSEMBLY)

Disconnect the R10 connector from the radio and

navigation assembly.

&nbs ...

USE SIMULATION METHOD TO CHECK

DTC B0113/42 Short to B+ in Side Squib RH Circuit

DESCRIPTION

The side squib RH circuit consists of the center airbag sensor assembly and

the front seat side airbag

assembly RH.

This circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0113/42 is recorded when a sh ...

Voice is not Recognized

INSPECTION PROCEDURE

1 CHECK NAVIGATION SETTINGS

Enter the "Menu" screen by pressing the "MENU" switch.

Select "Setup

Check that "Voice Recognition Guidance" is not OFF.

OK:

Voice Recognition Guidance is not OFF.

2 CHECK MAP DISC

...