Toyota Sienna Service Manual: Active Control Engine Mount System

DESCRIPTION

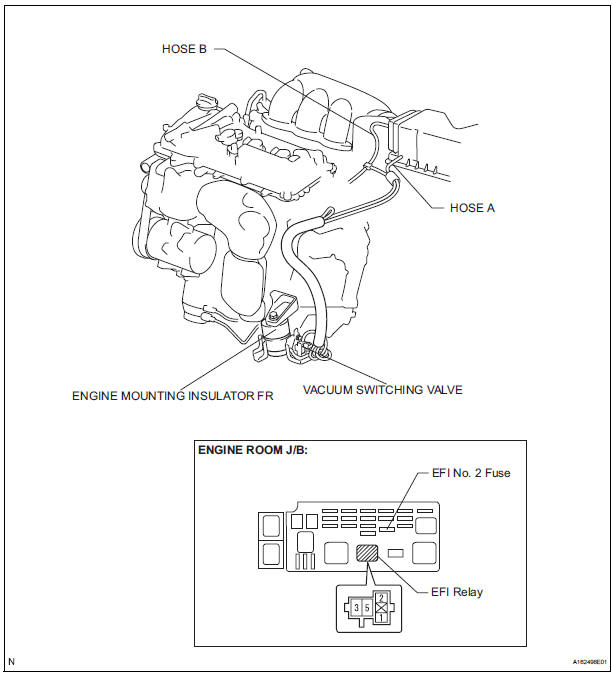

LOCATION

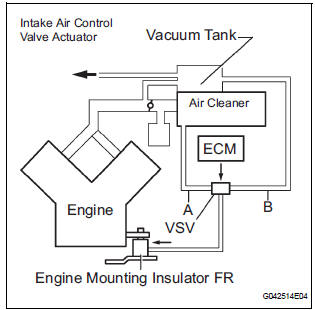

The Active Control Engine Mount (ACM) system decreases engine vibration at engine idling using the ACM VSV. The VSV is controlled by a pulse signal transmitted to the VSV from the ECM. The frequency of this pulse signal is matched to the engine speed to decrease engine vibration.

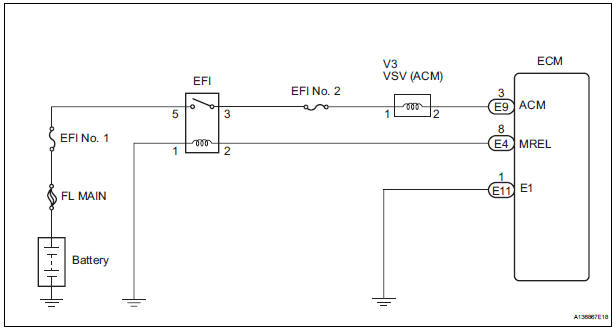

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK VACUUM HOSES

- If the hose is damaged, replace the vacuum hose assembly.

- Check the air and vacuum hoses for looseness, disconnection and blockage.

2 CHECK VACUUM

- Start the engine.

- Disconnect the vacuum hose from the air cleaner cap.

- Check that the disconnected port located on the vacuum

tank applies suction to your finger.

OK: Vacuum pressure exists.

- Reconnect the vacuum hose.

3 INSPECT ECM

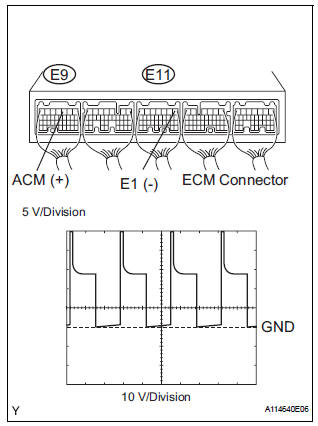

- Connect the oscilloscope between terminals ACM and E1 of the E9 and E11 ECM connectors.

- Warm up the engine to normal operating temperature.

- Turn the A/C switch on.

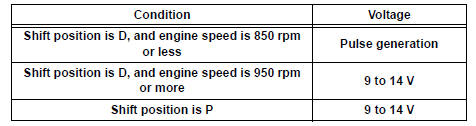

- Measure the voltage according to the value(s) in the table below.

Standard voltage

4 INSPECT DUTY VACUUM SWITCHING VALVE (RESISTANCE)

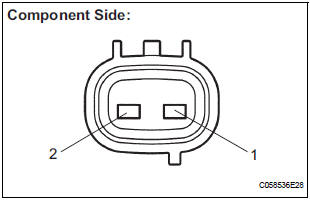

- Disconnect the V3 VSV for ACM connector.

- Measure the resistance according to the value(s) in the

table below.

Standard resistance: 19 to 21 Ω at 20C (68F)

- Reconnect the VSV for ACM connector.

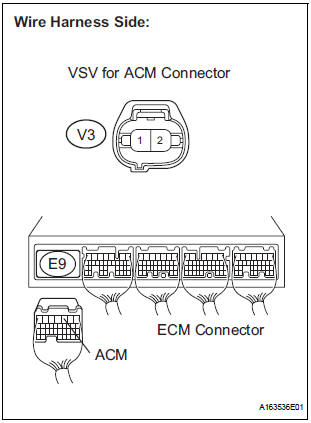

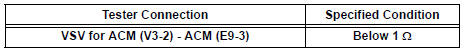

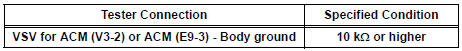

5 CHECK HARNESS AND CONNECTOR (VSV FOR ACM - ECM)

- Check the wire harness between the VSV for ACM connector and the ECM connector.

- Disconnect the V3 VSV for ACM connector.

- Disconnect the E9 ECM connector.

- Measure the resistance according to the value(s) in the table below.

Standard resistance: Check for open

Check for open

- Reconnect the ECM connector.

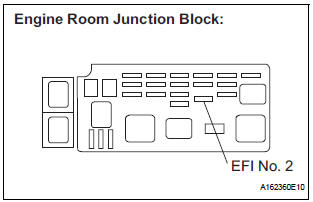

6 INSPECT FUSE (EFI NO. 2 FUSE)

- Remove the EFI No. 2 fuse from the engine room junction block.

- Measure the resistance according to the value(s) in the

table below.

Standard resistance: Below 1 Ω

- Reinstall the EFI No. 2 fuse.

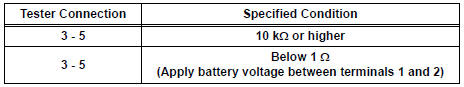

7 INSPECT RELAY (EFI RELAY)

- Remove the EFI relay from the engine room junction block.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

- Reinstall the EFI relay.

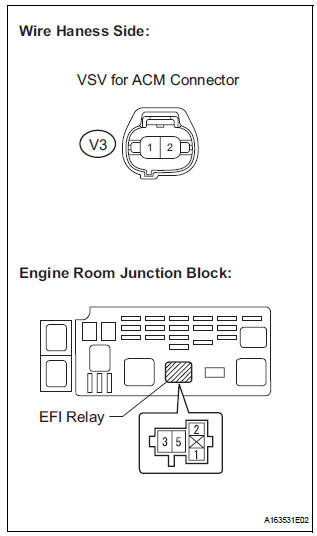

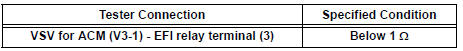

8 CHECK HARNESS AND CONNECTOR (VSV FOR ACM - EFI RELAY)

- Check the wire harness between the VSV for ACM and the EFI relay.

- Remove the EFI relay from the engine room junction block.

- Measure the resistance according to the value(s) in the table below.

Standard resistance: Check for open

- Reconnect the VSV for ACM connector.

- Reinstall the EFI relay.

CHECK ECM POWER SOURCE CIRCUIT

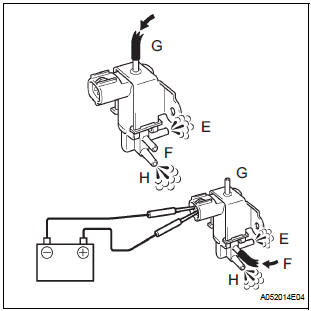

9 INSPECT DUTY VACUUM SWITCHING VALVE (OPERATION)

- Remove the VSV for ACM.

- Check operation of the VSV for ACM when positive

battery voltage is applied to the terminals of the VSV for

ACM connector.

Positive battery voltage is not applied: The air from pipe G is flowing out through pipes E and H.

Positive battery voltage is applied: The air from pipe F is flowing out through pipes E and H.

- Reinstall the VSV for ACM.

10 INSPECT ENGINE MOUNTING INSULATOR ASSEMBLY FRONT

- Disconnect the vacuum hose from the front engine mount insulator.

- Using a vacuum pump, apply vacuum of 80 kPa (600 mmHg, 25 in.Hg) and wait for 1 minute.

- Check that there is no change in the needle movement of the vacuum pump gauge.

- Check that there is no fluid leakage caused by a break in

the diaphragm.

OK: Vacuum pressure exists.

- Reconnect the vacuum hose.

SYSTEM OK

A/F Sensor Circuit Slow Response

A/F Sensor Circuit Slow Response

DTC P2A00 A/F Sensor Circuit Slow Response (Bank 1

Sensor 1)

DTC P2A03 A/F Sensor Circuit Slow Response (Bank 2

Sensor 1)

HINT:

DTC P2A00 indicates malfunctions related to the bank 1 A/F ...

EVAP System

EVAP System

RELATED DTCS

If any EVAP system DTCs are set, the malfunctioning area can be determined

using the table below.

NOTICE:

If the 0.02 inch reference pressure difference between the first and ...

Other materials:

Disassembly

1. FIX FRONT SHOCK ABSORBER WITH COIL SPRING

(a) Install 2 nuts and a bolt to the bracket at the lower

side of the front shock absorber with coil spring and

secure it in a vise.

2. REMOVE FRONT SUSPENSION SUPPORT SUBASSEMBLY LH

(a) Using SST, compress the front coil spring LH

SST 09727-300 ...

Oil and oil filter

COMPONENTS

REPLACEMENT

CAUTION:

Prolonged and repeated contact with engine oil will

result in the removal of natural oils from the skin,

leading to dryness, irritation and dermatitis. In

addition, used engine oil contains potentially harmful

contaminants which may caus ...

Vehicle load limits

Vehicle load limits include total load capacity, seating capacity,

TWR (Trailer Weight Rating) and cargo capacity

Total load capacity (vehicle capacity weight):

Total load capacity means the combined weight of occupants, cargo

and luggage.

Seating capacity

Without second center seat: 7 occupan ...