Toyota Sienna Service Manual: Brake Warning Light Remains ON

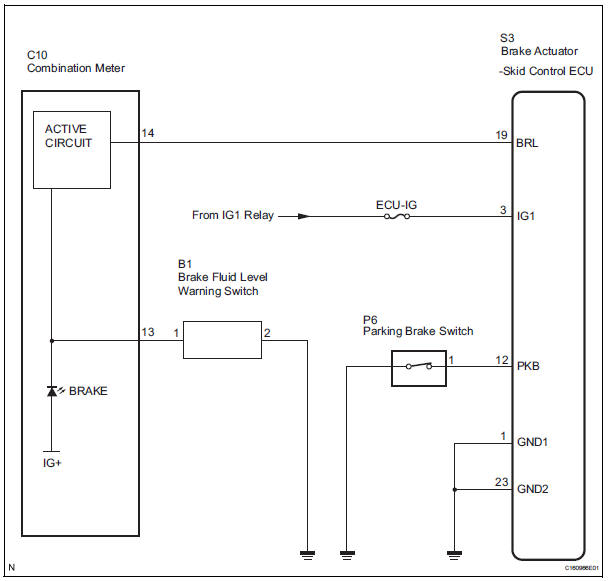

DESCRIPTION

If the ECU detects a trouble, it turns on the brake warning light at the same time of prohibiting ABS control.

At this time, the ECU records a DTC in memory.

Connect terminals TC and CG of the DLC3 to make the brake warning light blink and output the DTC.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK DTC

(a) Check if the ABS DTC is output (See page BC-10).

Result

2 INSPECT SKID CONTROL ECU CONNECTOR SECURELY CONNECTED

(a) Check the skid control ECU connector's connecting condition.

OK: The connector should be securely connected.

3 INSPECT BATTERY

(a) Check the battery voltage.

Standard voltage: 10 to 14 V

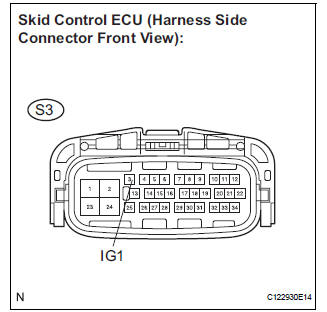

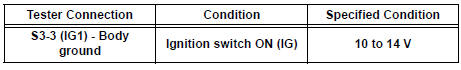

4 INSPECT SKID CONTROL ECU (IG1 TERMINAL VOLTAGE)

(a) Disconnect the skid control ECU connector.

(b) Turn the ignition switch to the on position.

(c) Measure the voltage according to the value(s) in the table below.

Standard voltage

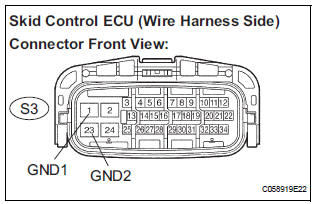

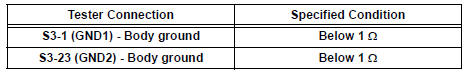

5 INSPECT SKID CONTROL ECU (GND TERMINAL CONTINUITY)

(a) Disconnect the skid control ECU connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

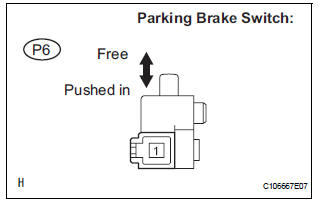

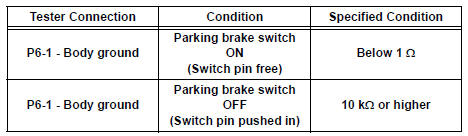

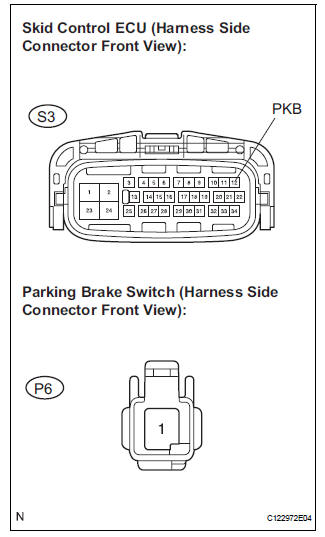

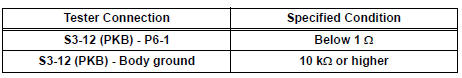

6 INSPECT PARKING BRAKE SWITCH

(a) Disconnect the parking brake switch connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

7 CHECK HARNESS AND CONNECTOR

(a) Disconnect the skid control ECU connector and parking brake switch.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

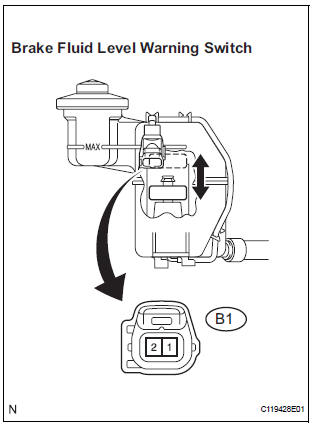

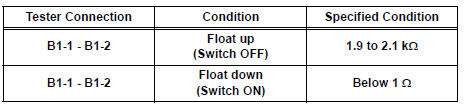

8 INSPECT BRAKE FLUID LEVEL WARNING SWITCH

(a) Remove the reservoir tank cap and strainer.

(b) Disconnect the brake fluid level warning switch connector.

(c) Measure the resistance according to the value(s) in the table below.

HINT: A float is placed inside the reservoir. Its position can be changed by increasing/decreasing the level of brake fluid.

Standard resistance

HINT: If there is no problem after finishing the above check, adjust the brake fluid level to the MAX level.

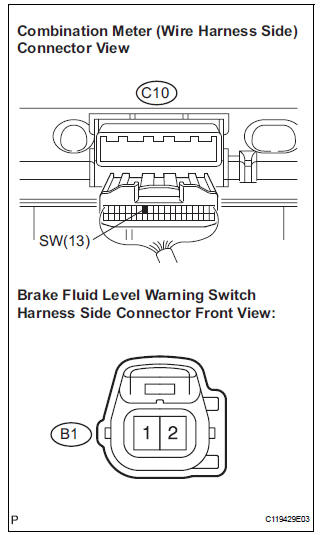

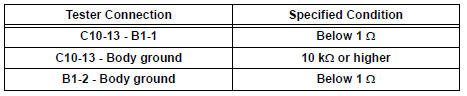

9 INSPECT HARNESS AND CONNECTOR (BETWEEN BRAKE FLUID LEVEL WARNING SW AND COMBINATION METER)

(a) Disconnect the combination meter connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

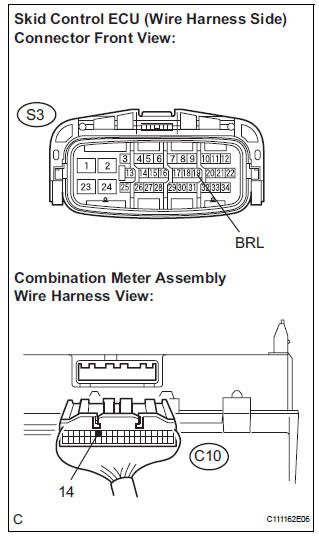

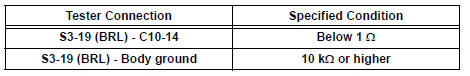

10 CHECK HARNESS AND CONNECTOR (BETWEEN SKID CONTROL ECU AND COMBINATION METER ASSEMBLY)

(a) Turn the ignition switch off.

(b) Disconnect the combination meter connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

11 INSPECT COMBINATION METER ASSEMBLY

(a) Check the combination meter assembly (See page ME- 4).

HINT: If troubleshooting has been carried out according to the PROBLEM SYMPTOMS TABLE, refer back to the table and proceed to the next step before replacing the part (See page BC-7).

REPLACE BRAKE ACTUATOR ASSEMBLY

ABS Warning Light does not Come ON

ABS Warning Light does not Come ON

WIRING DIAGRAM

See page BC-47.

INSPECTION PROCEDURE

1 INSPECT ABS WARNING LIGHT

(a) Disconnect the skid control ECU connector.

(b) Turn the ignition switch to the ON position.

(c) Check that ...

Brake Warning Light does not Come ON

Brake Warning Light does not Come ON

WIRING DIAGRAM

See page BC-52.

INSPECTION PROCEDURE

1 INSPECT BRAKE WARNING LIGHT

(a) Disconnect the skid control ECU connector.

(b) Turn the ignition switch to the on position.

(c) Check th ...

Other materials:

Seat Position Airbag Sensor Circuit Malfunction

DTC B1153/25 Seat Position Airbag Sensor Circuit Malfunction

DESCRIPTION

The seat position airbag sensor circuit consists of the center airbag sensor

assembly and the seat

position airbag sensor.

DTC B1153/25 is recorded when a malfunction is detected in the seat position

airbag sensor cir ...

Removal

1. REMOVE INSTRUMENT CLUSTER CENTER NO. 1 FINISH PANEL

2. REMOVE INSTRUMENT CLUSTER CENTER NO. 2

FINISH PANEL

3. REMOVE SHIFT LEVER KNOB SUB-ASSEMBLY

4. REMOVE POSITION INDICATOR HOUSING ASSEMBLY

5. REMOVE INSTRUMENT CLUSTER CENTER LOWER FINISH PANEL SUB-ASSEMBLY

6. REMOVE POWER POINT SOCKET A ...

Inspection

1. INSPECT TIRE PRESSURE WARNING RESET SWITCH

(a) Remove the tire pressure warning reset switch.

(b) Measure the resistance between terminals 1 and 2

of the tire pressure warning reset switch when the

tire pressure warning switch is ON and OFF.

Standard resistance

If the result is not as ...