Toyota Sienna Service Manual: Disassembly

1. INSPECT OIL PUMP ASSEMBLY

HINT: (See page AX-234)

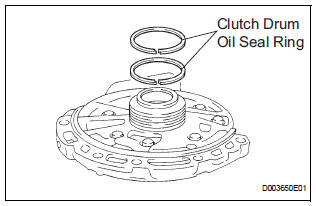

2. REMOVE CLUTCH DRUM OIL SEAL RING

(a) Remove the 2 clutch drum oil seal rings.

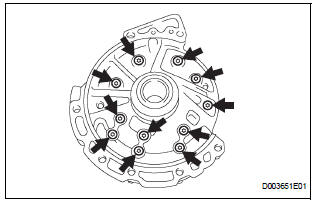

3. REMOVE STATOR SHAFT ASSEMBLY

(a) Using a "torx" socket (T30), remove the 11 bolts and stator shaft.

4. INSPECT CLEARANCE OF OIL PUMP ASSEMBLY

HINT: (See page AX-234)

5. REMOVE FRONT OIL PUMP DRIVE GEAR

(a) Remove the front oil pump drive gear.

6. REMOVE FRONT OIL PUMP DRIVEN GEAR

(a) Remove the front oil pump driven gear.

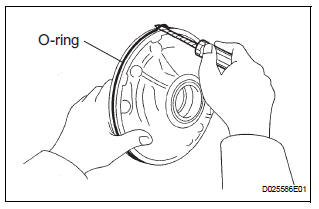

7. REMOVE FRONT OIL PUMP BODY O-RING

(a) Using a screwdriver, remove the O-ring.

HINT: Tape the screwdriver before use.

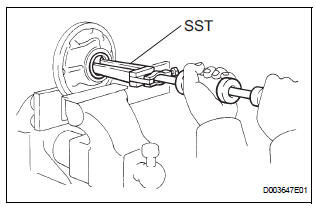

8. REMOVE FRONT OIL PUMP OIL SEAL

(a) Mount the oil pump in a soft jaw vise.

(b) Using SST, remove the oil seal from the oil pump body.

SST 09308-00010

Oil pump

Oil pump

COMPONENTS

...

Inspection

Inspection

1. INSPECT OIL PUMP ASSEMBLY

(a) Turn the drive gear with the 2 screwdrivers and

make sure that it rotates smoothly.

NOTICE:

Be careful not to damage the oil seal lip.

2. INSPEC ...

Other materials:

Installation

1. INSTALL ECM

Install the ECM with the 2 nuts.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

Connect the 5 ECM connectors.

2. INSTALL ECM (with 10 speakers system)

Install the ECM and stereo components amplifier

with the 4 nuts.

Torque: 5.5 N*m (56 kgf*cm, 49 ...

Transmission Fluid Temperature Sensor "A"

Performance

DESCRIPTION

The ATF (Automatic Transmission Fluid) temperature sensor converts the fluid

temperature into a

resistance value which is input into the ECM.

MONITOR DESCRIPTION

The ATF temperature sensor converts the ATF temperature to an electrical

resistance value. Based on

the resis ...

Confirmation of transmitter id registration

(a) Make sure that the ignition switch is off.

(b) Connect the intelligent tester to DLC3.

(c) Turn the ignition switch to the ON position.

(d) Select "TIREPRESS" by following the prompts

displayed on the intelligent tester.

(e) Confirm that the data of tire pressure of all ti ...