Toyota Sienna Service Manual: Inspection

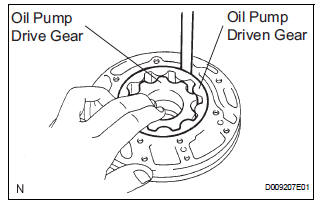

1. INSPECT OIL PUMP ASSEMBLY

(a) Turn the drive gear with the 2 screwdrivers and make sure that it rotates smoothly.

| NOTICE: Be careful not to damage the oil seal lip. |

2. INSPECT CLEARANCE OF OIL PUMP ASSEMBLY

(a) Push the driven gear to one side of the body.

(b) Using a feeler gauge, measure the clearance.

Standard body clearance: 0.10 to 0.17 mm (0.0039 to 0.0067 in.) Side clearance: 0.02 to 0.05 mm (0.001 to 0.002 in.) Maximum body clearance: 0.17 mm (0.0067 in.)

If the body clearance is greater than the maximum, replace the oil pump body sub-assembly.

(c) Using a feeler gauge, measure the tip clearance between the driven gear teeth and drive gear teeth.

Standard tip clearance: 0.07 to 0.15 mm (0.0028 to 0.0059 in.) Maximum tip clearance: 0.15 mm (0.0059 in.)

If the tip clearance is greater than the maximum, replace the oil pump body sub-assembly.

(d) Using a straightedge and feeler gauge, measure the side clearance of both gears.

Standard side clearance: 0.02 to 0.05 mm (0.0008 to 0.0020 in.) Maximum side clearance: 0.05 mm (0.0020 in.)

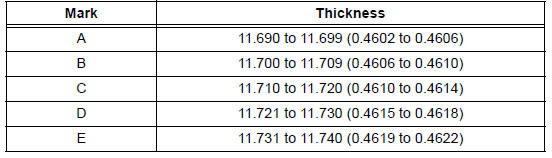

Drive gear thickness: mm (in.)

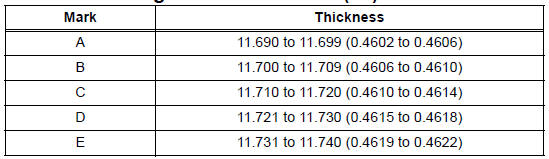

Driven gear thickness: mm (in.)

3. INSPECT FRONT OIL PUMP AND GEAR BODY SUBASSEMBLY

(a) Using a dial indicator, measure the inside diameter of the oil pump body bushing.

Standard inside diameter: 38.113 to 38.138 mm (1.50051 to 1.50149 in.) Maximum inside diameter: 38.188 mm (1.50346 in.)

If the inside diameter is greater than the maximum, replace the oil pump body sub-assembly.

4. INSPECT STATOR SHAFT ASSEMBLY

(a) Using a dial indicator, measure the inside diameter of the stator shaft.

Standard inside diameter: 21.500 to 21.526 mm (0.84646 to 0.84748 in.) Maximum inside diameter: 21.57 mm (0.8492 in.)

If the inside diameter is greater than the maximum, replace the stator shaft.

Disassembly

Disassembly

1. INSPECT OIL PUMP ASSEMBLY

HINT:

(See page AX-234)

2. REMOVE CLUTCH DRUM OIL SEAL RING

(a) Remove the 2 clutch drum oil seal rings.

3. REMOVE STATOR SHAFT ASSEMBLY

(a) Using a "torx&q ...

Reassembly

Reassembly

1. INSTALL FRONT OIL PUMP OIL SEAL

(a) Using SST and a hammer, install a new oil seal to

the oil pump body.

SST 09350-32014 (09351-32140)

HINT:

The seal end should be flat with the outer edge ...

Other materials:

Repair

1. INTRODUCTION

(a) This section introduces ways to determine whether

the run-flat tire is repairable or not. Repair must be

performed by following the appropriate procedures.

If a flat tire occurs, it is possible to drive a maximum

of 160 km (100 miles) at a speed below 90 km/h (55

mph) due ...

Door LOCK Position Circuit

DESCRIPTION

This circuit detects the state of the door lock detection sensor and send it

to the Multiplex network body

ECU.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 READ VALUE OF INTELLIGENT TESTER

Connect the intelligent tester to DLC3.

Turn the ignition switch ON and push the i ...

If the shift lever cannot

be shifted from P

If the shift lever cannot be shifted with your foot on the brake

pedal, there may be a problem with the shift lock system (a system

to prevent accidental operation of the shift lever). Have the

vehicle inspected by your Toyota dealer immediately.

The following steps may be used as an emergency ...