Toyota Sienna Service Manual: Disassembly

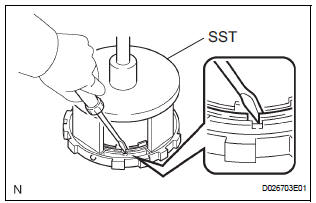

1. REMOVE 2ND BRAKE PISTON RETURN SPRING SUB-ASSEMBLY

(a) Place SST on the return spring and compress the return spring with a press.

SST 09387-00060

(b) Using a screwdriver, remove the snap ring.

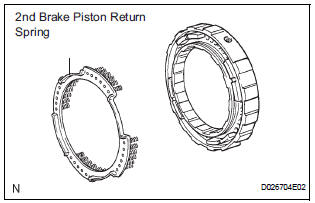

(c) Remove the 2nd brake piston return spring.

2. REMOVE 2ND BRAKE PISTON

(a) Hold the 2nd brake piston and apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the 2nd brake cylinder to remove the 2nd brake piston.

NOTICE: Hold the piston with a shop rag or a piece of cloth when removing the piston. Failure to do so may result in the piston jumping out from the cylinder.

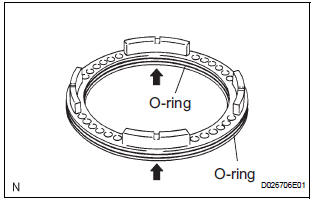

3. REMOVE 2ND BRAKE PISTON O-RING

(a) Remove the 2 O-rings from the 2nd brake piston.

Second brake piston

Second brake piston

COMPONENTS

...

Inspection

Inspection

1. INSPECT 2ND BRAKE PISTON RETURN SPRING

SUB-ASSEMBLY

(a) Using vernier calipers, measure the free length of

the spring together with the spring seat.

Standard free length:

16.61 mm (0.6539 ...

Other materials:

Inspection

1. INSPECT SHOCK ABSORBER ASSEMBLY FRONT LH

(a) Compress and extend the shock absorber rod and

check that there is no unusual resistance or unusual

sound during operation.

If there is any abnormality, replace the shock

absorber assembly front LH with a new one.

NOTICE:

When disposing of ...

Removal

1. REMOVE ROOF DRIP SIDE FINISH MOULDING

Put protective tape around the roof drip side finish

moulding.

Using a remover for the roof moulding, disengage of

the clips both in the front and rear ends of the roof

drip side finish moulding and then remove the roof

drip side finish moul ...

Air Inlet Damper Position Sensor Circuit

DESCRIPTION

This sensor detects the position of the air inlet control servo motor and

sends the appropriate signals to

the A/C amplifier. The position sensor is built in the air inlet control servo

motor.

The position sensor's resistance changes as the air inlet control servo motor

ar ...