Toyota Sienna Service Manual: Disassembly

1. INSPECT PACK CLEARANCE OF FORWARD CLUTCH

HINT: (See page AX-242)

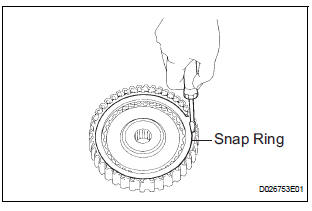

2. REMOVE FORWARD MULTIPLE DISC CLUTCH DISC

(a) Using a screwdriver, remove the snap ring.

(b) Remove the flange, 5 discs and 5 plates from the input shaft assembly.

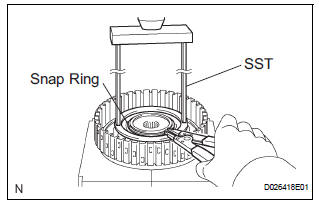

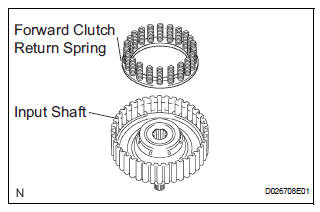

3. REMOVE FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY

(a) Place SST on the spring retainer and compress the return spring with a press.

(b) Using a snap ring expander, remove the snap ring.

NOTICE:

- Stop the press when the spring seat is lowered 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove, preventing the spring seat from being deformed.

- Do not expand the snap ring excessively.

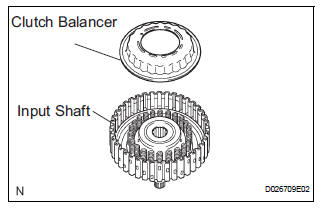

(c) Remove the clutch balancer from the input shaft.

(d) Remove the forward clutch return spring from the input shaft.

4. REMOVE FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY

(a) Place the forward clutch drum onto the oil pump.

(b) Holding the forward clutch piston by hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the oil pump to remove the forward clutch piston.

HINT:

When the piston cannot be removed as it is slanted, blow air again with the protruding side pushed, or remove the piston using the needle nose pliers with vinyl tape on the tip.

5. REMOVE INPUT SHAFT OIL SEAL RING

(a) Remove the input shaft oil seal ring from the input shaft.

Forward clutch

Forward clutch

Components

...

Inspection

Inspection

1. INSPECT PACK CLEARANCE OF FORWARD CLUTCH

(a) Install the forward clutch on the oil pump.

NOTICE:

Be careful not to damage the oil seal ring of oil

pump.

b) Using a dial indicator, measure ...

Other materials:

Problem symptoms table

If there are no DTCs output but the problem still occurs,

check the circuits for each problem symptom in the order

given in the table below and proceed to the relevant

troubleshooting page.

NOTICE:

When replacing the brake actuator assembly, sensor,

etc., turn the ignition switch off.

HINT:

...

No Answer-Back (Hazard Warning Light and Wireless Door Lock

Buzzer)

DESCRIPTION

If there is no answer-back of the hazard light signal and the wireless door lock

buzzer although the

wireless control function is operating normally, there might be a malfunction in

the hazard light signal and

the wireless door lock buzzer signal which are output from the multiple ...

Manual Up / Down Function does not Operate on Rear RH Only

DESCRIPTION

If the manual UP/DOWN function does not operate, the power window motor, the

regulator switch or the

wire harness may be malfunctioning.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK WIRE HARNESS (POWER SOURCE)

Disconnect the P39 regulator switch connector.

Turn ...