Toyota Sienna Service Manual: Occupant Classification Sensor Power Supply Circuit Malfunction

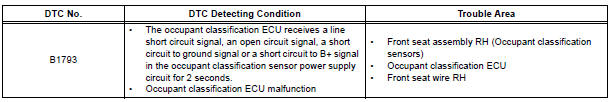

DTC B1793 Occupant Classification Sensor Power Supply Circuit Malfunction

DESCRIPTION

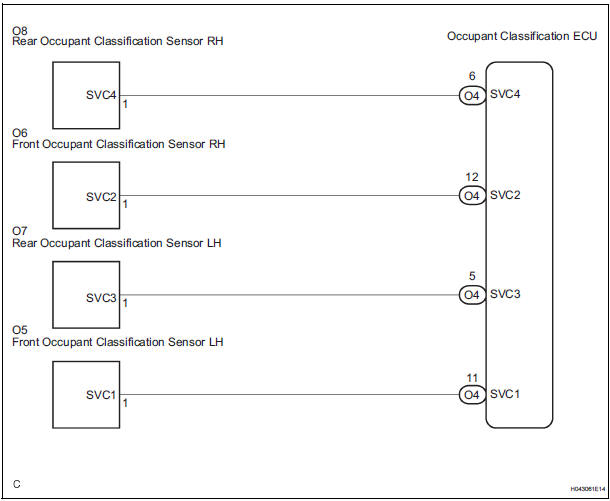

The occupant classification sensor power supply circuit consists of the occupant classification ECU and the occupant classification sensors.

DTC B1793 is recorded when a malfunction is detected in the occupant classification sensor power supply circuit

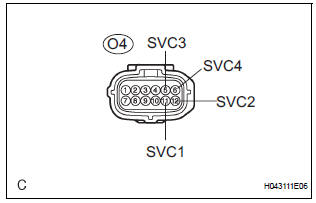

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

- If troubleshooting (wire harness inspection) is difficult to perform, remove the front passenger seat installation bolts to see the under surface of the seat cushion.

- In the above case, hold the seat so that it does not fall down. Holding the seat for a long period of time may cause a problem, such as seat rail deformation. Hold the seat only as necessary.

1 CHECK DTC

- Turn the ignition switch to the ON position.

- Clear the DTCs stored in the memory.

HINT: First clear DTCs stored in the occupant classification ECU and then in the center airbag sensor assembly.

- Turn the ignition switch to the LOCK position.

- Turn the ignition switch to the ON position.

- Check the DTCs.

OK: DTC B1793 is not output.

HINT: Codes other than DTC B1793 may be output at this time, but they are not related to this check.

2 CHECK CONNECTION OF CONNECTORS

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Check that the connectors are properly connected to the occupant classification ECU and the occupant classification sensors.

OK: The connectors are properly connected.

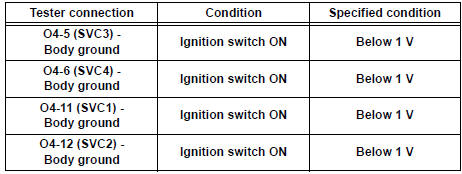

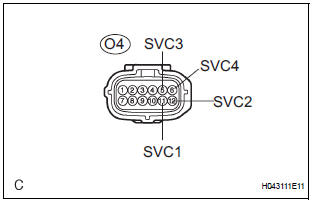

3 CHECK FRONT SEAT WIRE RH (SHORT TO B+)

- Disconnect the connectors from the occupant classification ECU and the 4 occupant classification sensors.

- Connect the negative (-) terminal cable to the battery.

- Turn the ignition switch to the ON position.

- Measure the voltage according to the value(s) in the table below.

Standard voltage

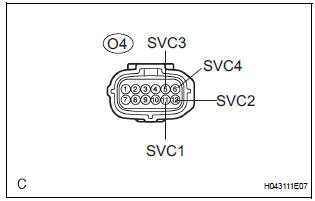

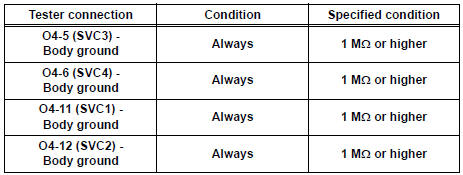

4 CHECK FRONT SEAT WIRE RH (SHORT TO GROUND)

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

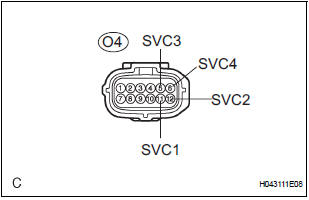

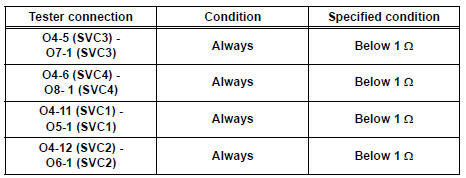

5 CHECK FRONT SEAT WIRE RH (OPEN)

- Measure the resistance according to the value(s) in the table below.

Standard resistance

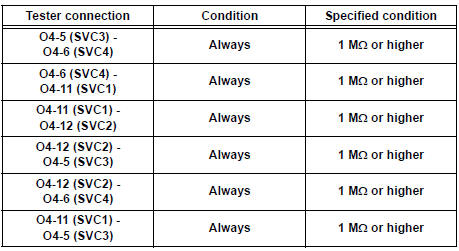

6 CHECK FRONT SEAT WIRE RH (SHORT)

- Measure the resistance according to the value(s) in the table below.

Standard resistance

7 CHECK DTC

- Connect the connectors to the occupant classification ECU and the 4 occupant classification sensors.

- Connect the negative (-) terminal cable to the battery.

- Turn the ignition switch to the ON position.

- Clear the DTCs stored in the memory

HINT: First clear DTCs stored in the occupant classification ECU and then in the center airbag sensor assembly. - Turn the ignition switch to the LOCK position.

- Turn the ignition switch to the ON position.

- Check the DTCs.

OK: DTC B1793 is not output.

HINT: Codes other than DTC B1793 may be output at this time, but they are not related to this check.

8 REPLACE OCCUPANT CLASSIFICATION ECU

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Replace the occupant classification ECU.

HINT: Perform the inspection using parts from a normal vehicle if possible.

9 PERFORM ZERO POINT CALIBRATION

- Connect the negative (-) terminal cable to the battery.

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Using the intelligent tester, perform "Zero point calibration".

OK: "COMPLETED" is displayed.

10 PERFORM SENSITIVITY CHECK

- Using the intelligent tester, perform "Sensitivity check".

Standard value: 27 to 33 kg (59.52 to 72.75 lb)

11 CHECK DTC

- Turn the ignition switch to the ON position.

- Clear the DTCs stored in the memory.

HINT: First clear DTCs stored in the occupant classification ECU and then in the center airbag sensor assembly.

- Turn the ignition switch to the LOCK position.

- Turn the ignition switch to the ON position.

- Check the DTCs.

OK: DTC B1793 is not output.

HINT: Codes other than DTC B1793 may be output at this time, but they are related to this check.

12 REPLACE FRONT SEAT ASSEMBLY RH

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Replace the front seat assembly RH ( for flat type, SE-48 for manual seat, SE-58 for power seat).

13 PERFORM ZERO POINT CALIBRATION

- Connect the negative (-) terminal cable to the battery.

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Using the intelligent tester, perform "Zero point calibration".

OK: "COMPLETED" is displayed.

14 PERFORM SENSITIVITY CHECK

- Using the intelligent tester, perform "Sensitivity check".

Standard value: 27 to 33 kg (59.52 to 72.75 lb)

END

Center Airbag Sensor Assembly Communication

Circuit Malfunction

Center Airbag Sensor Assembly Communication

Circuit Malfunction

DTC B1790 Center Airbag Sensor Assembly Communication

Circuit Malfunction

DESCRIPTION

The center airbag sensor assembly communication circuit consists of the

occupant classification ECU and

the ...

Open in Occupant Classification ECU Battery

Positive Line

Open in Occupant Classification ECU Battery

Positive Line

DTC B1794 Open in Occupant Classification ECU Battery

Positive Line

DESCRIPTION

This circuit consists of the occupant classification ECU and the power source

circuit (battery, fuse, wire

harness ...

Other materials:

Installation

1. INSTALL OUTSIDE MOULDING

Using a heat light, heat the mounting surface of the

vehicle body between 40 to 60 C (104 to 140 F).

NOTICE:

Do not heat the body excessively.

Remove the tape from the vehicle body.

Wipe off the stains with cleaner.

Clean the outside moulding (if reusing t ...

Cruise Main Indicator Light Circuit

DESCRIPTION

The ECM detects a cruise control switch signal and sends it to the

combination meter through CAN

and BEAN. Then the CRUISE main indicator light comes on.

The CRUISE main indicator light circuit uses CAN and BEAN for

communication. If there is a

malfunction in ...

Power slide door control motor and clutch

INSPECTION

1. INSPECT SLIDE DOOR CONTROL MOTOR AND CLUTCH ASSEMBLY LH

Remove the motor and clutch.

Connect the battery positive (+) lead to terminal 3

and the battery negative (-) lead to terminal 2.

Apply battery voltage to the terminals and check the

motor operation.

OK

If ...