Toyota Sienna Service Manual: Disassembly

1. INSPECT PACK CLEARANCE OF REVERSE CLUTCH

HINT: (See page AX-249)

2. INSPECT PACK CLEARANCE OF DIRECT CLUTCH AND OVERDRIVE CLUTCH

HINT: (See page AX-249)

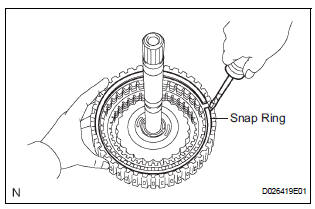

3. REMOVE DIRECT MULTIPLE DISC CLUTCH DISC

(a) Using a screwdriver, remove the snap ring from the intermediate shaft.

(b) Remove the flange, 3 discs, 3 plates and cushion plate from the intermediate shaft.

4. REMOVE OVERDRIVE DIRECT CLUTCH DISC

(a) Using a screwdriver, remove the snap ring from the intermediate shaft.

(b) Remove the flange, 4 discs and 4 plates from the intermediate shaft.

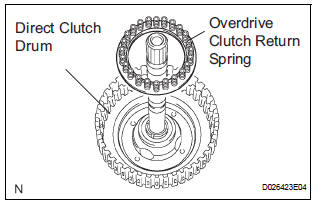

5. REMOVE OVERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY

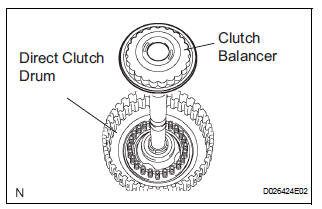

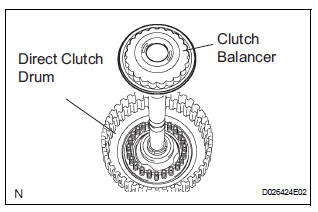

(a) Place SST on the clutch balancer and compress the spring with a press.

SST 09387-00020

(b) Using a snap ring expander, remove the snap ring from the direct clutch drum.

NOTICE:

- Stop the press when the spring seat is lowered to the place 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove.

- This prevents the spring seat from being deformed.

- Do not expand the snap ring excessively.

- This prevents the spring seat from being deformed.

- Do not expand the snap ring excessively.

(c) Remove the clutch balancer from the direct clutch drum.

(d) Remove the overdrive clutch return spring from the direct clutch drum.

6. REMOVE OVERDRIVE DIRECT CLUTCH PISTON

(a) Install the intermediate shaft on the transaxle rear cover.

(b) Holding the direct clutch piston with your hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the transaxle rear cover to remove the direct clutch piston.

7. REMOVE OVERDRIVE DIRECT CLUTCH DRUM SUBASSEMBLY

(a) Holding the direct clutch drum by hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the transaxle rear cover to remove the direct clutch drum.

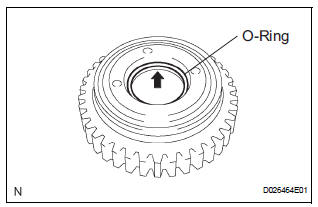

8. REMOVE OVERDRIVE DIRECT CLUTCH O-RING

(a) Using a screwdriver, remove the O-ring from the direct clutch drum.

Direct clutch

Direct clutch

Components

...

Inspection

Inspection

1. Inspect pack clearance of reverse clutch

(A) install the intermediate shaft and needle roller

bearing onto the transaxle rear cover.

(B) using a dial indicator, measure the reverse clutch

...

Other materials:

Installation

1. INSTALL REAR SEAT 3 POINT TYPE BELT

ASSEMBLY (for 8-Passenger)

HINT: Refer to the instructions for reassembly of the rear

No. 1 seat assembly (for center seat).

Install the rear seat 3 point type belt assembly with

the bolt.

Torque: 42 N*m (430 kgf*cm, 31 ft.*lbf)

2. INSTALL ...

Short in Side Squib LH Circuit

DTC B0115/47 Short in Side Squib LH Circuit

DESCRIPTION

The side squib LH circuit consists of the center airbag sensor assembly and

the front seat side airbag

assembly LH.

This circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0115/47 is recorded when a short ci ...

Reassembly

1. INSTALL UNDERDRIVE CLUTCH DRUM O-RING

(a) Coat a new O-ring with ATF, and install it to the

underdrive clutch drum.

NOTICE:

Make sure that the O-ring is not twisted or

pinched.

2. INSTALL UNDERDRIVE CLUTCH PISTON SET

(a) Coat the underdrive clutch piston with ATF, and

install it t ...