Toyota Sienna Service Manual: Disassembly

1. SEPARATE REAR DRIVE SHAFT INBOARD JOINT BOOT CLAMP

(a) Using a screwdriver, remove the 2 rear drive shaft inboard joint boot clamps as shown in the illustration.

2. SEPARATE REAR DRIVE SHAFT INBOARD JOINT BOOT

(a) Separate the rear drive shaft inboard joint boot from the inboard joint assembly.

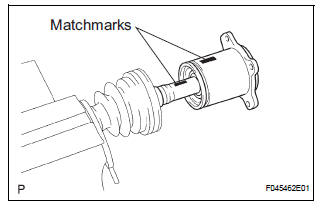

3. REMOVE REAR DRIVE SHAFT INBOARD JOINT ASSEMBLY

(a) Put matchmarks on the inboard joint assembly and outboard joint shaft.

NOTICE: Do not use a punch for the marks.

(b) Pull out the inboard joint assembly.

NOTICE: Be careful not to drop the balls.

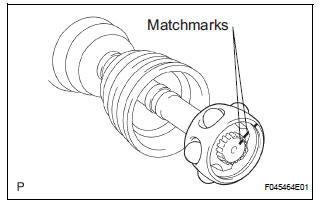

(c) Place matchmarks on the outboard joint shaft, inner race and cage.

NOTICE: Do not punch the marks.

(d) Remove the 6 bolts.

(e) Slide the cage toward outboard joint.

(f) Using a snap ring expander, remove the snap ring.

(g) Using a brass bar and hammer, remove the inner race.

(h) Remove the cage.

(i) Remove the inboard joint boot, inboard joint boot clamp and inboard joint boot No. 2 clamp.

4. REMOVE REAR DRIVE SHAFT OUTBOARD JOINT BOOT CLAMP

(a) Using pliers, remove the 2 rear drive shaft outboard joint boot clamps as shown in the illustration.

5. REMOVE REAR DRIVE SHAFT OUTBOARD JOINT BOOT

(a) Remove the outboard joint boot from the outboard joint shaft.

(b) Remove the old grease from the outboard joint.

NOTICE: Do not disassemble the outboard joint.

Removal

Removal

1. REMOVE REAR WHEEL

2. REMOVE TAIL EXHAUST PIPE ASSEMBLY (See page

EX-8)

3. SEPARATE REAR SPEED SENSOR

(a) Remove the bolt and the speed sensor from the

axle carrier.

NOTICE:

Be careful not ...

Inspection

Inspection

1. INSPECT REAR DRIVE SHAFT ASSEMBLY LH

(a) Check that there is no remarkable play in the radial

direction of the outboard joint.

(b) Check that the inboard joint slides smoothly in the

thru ...

Other materials:

Compressor and magnetic clutch

COMPONENTS

...

On-vehicle inspection

1. INSPECT THROTTLE BODY

(a) Listen to the throttle control motor operating sounds.

(1) Turn the ignition switch to the ON position.

(2) When pressing the accelerator pedal position

sensor lever, listen to the running motor. Make

sure that no friction noise comes from the

motor.

If fricti ...

Console box

Press the tab.

Type A

Type B

Sliding the console box (type B)

From front

Press the tab and slide the console box.

From rear

Pull up the lever and slide the console

box.

Console box light

The console box light turns on when the headlight switch is on.

...