Toyota Sienna Service Manual: Electronic control

(a) REMOVAL AND INSTALLATION OF BATTERY TERMINAL

REMOVAL AND INSTALLATION OF BATTERY TERMINAL

REMOVAL AND INSTALLATION OF BATTERY TERMINAL

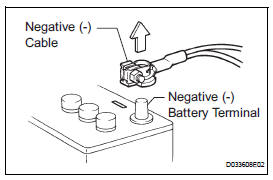

(1) Before performing electronic work, disconnect the cable from the negative (-) battery terminal to prevent component and wire damage caused by accidental short circuits.

(2) When disconnecting the cable, turn the ignition switch and headlight dimmer switch off and loosen the cable nut completely. Perform these operations without twisting or prying the cable.

Then disconnect the cable.

(3) Clock settings, radio settings, audio system memory, DTCs and other data are erased when the cable is disconnected from the negative (-) battery terminal. Write down any necessary data before disconnecting the cable.

(b) HANDLING OF ELECTRONIC PARTS

HANDLING OF ELECTRONIC PARTS

HANDLING OF ELECTRONIC PARTS

(1) Do not open the cover or case of the ECU unless absolutely necessary. If the IC terminals are touched, the IC may be rendered inoperative by static electricity.

(2) Do not pull the wires when disconnecting electronic connectors. Pull the connector itself.

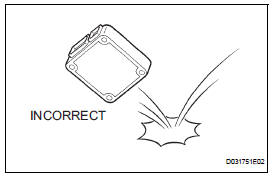

(3) Do not drop electronic components, such as sensors or relays. If they are dropped on a hard surface, they should be replaced.

(4) When cleaning the engine with steam, protect the electronic components, air filter and emission-related components from water.

(5) Never use an impact wrench to remove or install temperature switches or temperature sensors.

(6) When measuring the resistance between terminals of a wire connector, insert the tester probe carefully to prevent terminals from bending.

For vehicles equipped with srs airbag and seat belt pretensioner

For vehicles equipped with srs airbag and seat belt pretensioner

The SIENNA is equipped with a Supplemental Restraint System (SRS).

CAUTION: Failure to carry out the service operations in the correct sequence could cause the SRS to unexpectedly deploy during se ...

Removal and installation of fuel control parts

Removal and installation of fuel control parts

(a) PLACE FOR REMOVING AND INSTALLING FUEL

SYSTEM PARTS

(1) Work in a location with good air ventilation that

does not have welders, grinders, drills, electric

motors, stoves, or any other ignitio ...

Other materials:

Pressure Control Solenoid "C" Performance (Shift

Solenoid Valve SL3)

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear

position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory

to detect mechanical

troubles of the shift solenoid valves and valve bo ...

Short in Driver Side Squib 2nd Step Circuit

DTC B1180/17 Short in Driver Side Squib 2nd Step Circuit

DESCRIPTION

The driver side squib 2nd step circuit consists of the center airbag sensor

assembly, the spiral cable and

the steering pad.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B1180/17 is rec ...

How to proceed with

troubleshooting

The intelligent tester can be used in steps 4, 6, 8 and 9.

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS

3 PASSENGER AIRBAG ON/OFF INDICATOR CHECK

4 DTCs CHECK (Present and Past DTCs)

Check for DTCs.

Result

GO TO PROBLEM SYMPTOMS TABLE

5 DTCs CHART

6 CIRCUIT ...