Toyota Sienna Service Manual: Hood

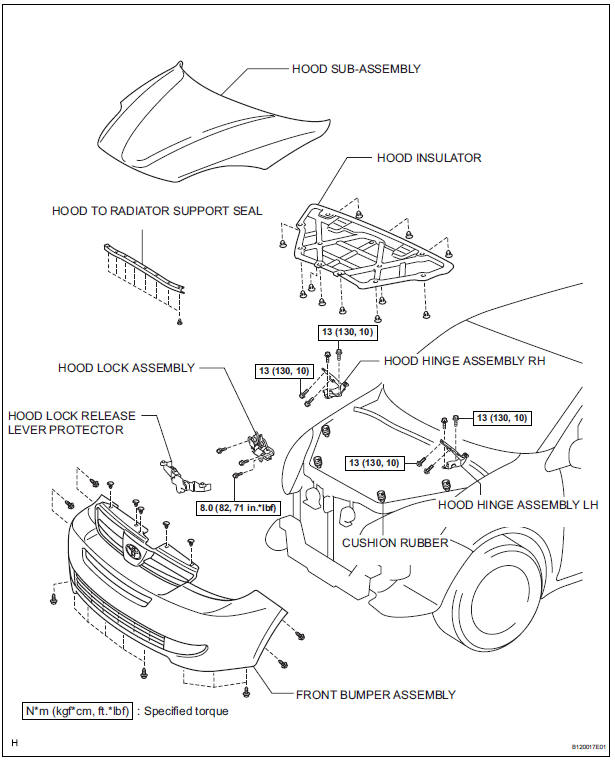

COMPONENTS

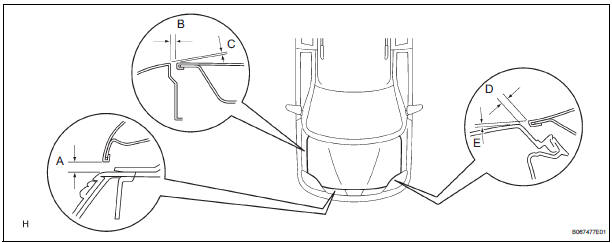

Adjustment

HINT: Since a centering bolt is used as a hood hinge mounting bolt and hood lock mounting bolt, the hood and hood lock can not be adjusted with them on. Substitute a bolt with a washer for the centering bolt.

1. INSPECT HOOD SUB-ASSEMBLY

- Check that the clearance is within the standard range.

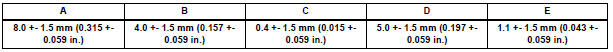

Standard

2. ADJUST HOOD SUB-ASSEMBLY

- Horizontally adjust the hood.

- Loosen the 4 hood hinge mounting bolts on the hood side.

- Adjust the clearance by moving the hood, so

that it will be in the standard range.

Standard (A): 4.0 +- 1.5 mm (0.157 +- 0.059 in.)

- Tighten the hood side hinge bolts after the

adjustment.

Torque: 13 N*m (130 kgf*cm, 10 ft.*lbf)

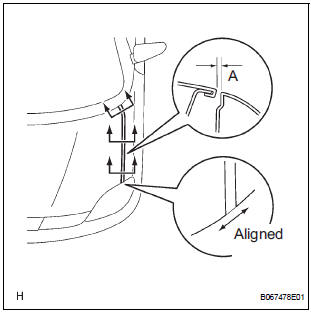

- Adjust the height of the hood front end using the cushion rubber.

- Adjust the cushion rubber so that the hood and the fender will be aligned.

HINT: The cushion rubber goes up and down when turned.

- Adjust the hood lock.

- Remove the front bumper cover (See page ET- 3).

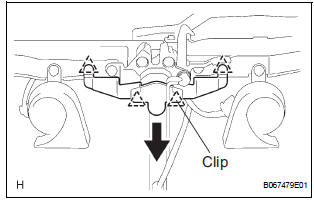

- Using a screwdriver, disengage the 4 claws and remove the hood lock release lever protector.

HINT: Tape the screwdriver tip before use.

NOTICE: Removing the protector damages the clips inside the protector. Therefore, the use of a new protector is necessary for installation.

- Loosen the 3 hood lock mounting bolts.

- Adjust the striker position by moving the hood lock, so that the striker can enter smoothly.

- Tighten the hood lock bolts after the

adjustment.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

Power Back Door Warning Buzzer does not Sound

Power Back Door Warning Buzzer does not Sound

DESCRIPTION

The power back door system uses a warning buzzer built into the

back door, which has 3 ways of

sounding that are used differently according to the situations:

When all the f ...

Front door

Front door

COMPONENTS

...

Other materials:

Shift Solenoid "E" Control Circuit

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or

short circuit occurs in

either of the shift solenoid valves, the ECM cont ...

Reassembly

1. INSTALL INPUT SHAFT OIL SEAL RING

(a) Compress a new input shaft oil seal ring from both

sides to reduce dimension A.

Dimension A:

5 mm (0.197 in.)

(b) Coat the oil seal ring with ATF and install it to the

input shaft.

NOTICE:

Do not expand the end gap of the oil seal ring

too much. ...

Read vin (vehicle identification number)

(a) The VIN reading process is shown in the flowchart

below. Reading the VIN stored in the ECM is

necessary when comparing it to the VIN provided

with the vehicle.

(b) Read the VIN using the intelligent tester.

(c) Check the vehicle's VIN.

(d) Connect the intelligent tester to the DLC3.

...