Toyota Sienna Service Manual: How to use this manual

GENERAL INFORMATION

1. GENERAL DESCRIPTION

(a) This manual is written in accordance with SAE J2008.

(b) Repair operations can be separated mainly in the following 3 processes:

(1) Diagnosis

(2) Removing / Installing, Replacing, Disassembling / Reassembling, Checking and Adjusting

(3) Final Inspection

(c) The following procedures are omitted from this manual. However, these procedures must be performed.

(1) Use a jack or lift to perform operations

(2) Clean all removed parts

(3) Perform a visual check

2. INDEX

(a) An alphabetical INDEX section is provided at the end of the manual as a reference to help you find the item to be repaired.

3. PREPARATION

(a) Use of Special Service Tools (SST) and Special Service Materials (SSM) may be required, depending on the repair procedure. Be sure to use SST and SSM when they are required and follow the working procedure properly. A list of SST and SSM is in the "Preparation" section of this manual.

4. REPAIR PROCEDURES

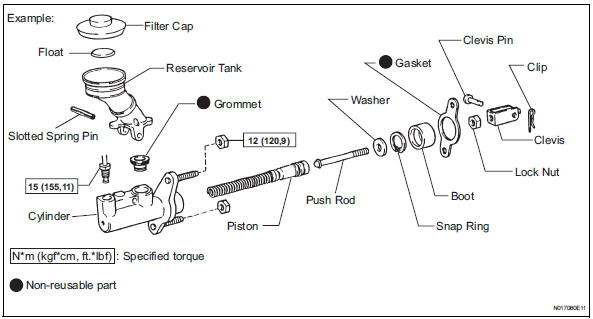

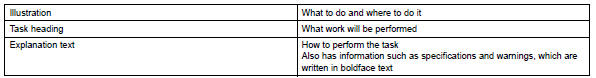

(a) A component illustration is placed under the title where necessary. (b) Non-reusable parts, grease application areas, precoated parts and torque specifications are noted in the component illustrations. The following illustration is an example.

(c) Torque specifications, grease application areas and non-reusable parts are emphasized in th procedures.

HINT There are cases where such information can onl be explained by using an illustration. In these cases torque, oil and other information are described in th illustration

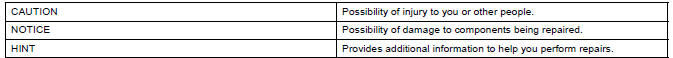

(d) Only items with key points are described in the text What to do and other details are explained usin illustrations next to the text. Both the text an illustrations are accompanied by standard value and notices.

(e) Illustrations of similar vehicle models are sometimes used. In these cases, minor details may be different from the actual vehicle.

(f) Procedures are presented in a step-by-step format.

5. SERVICE SPECIFICATIONS

(a) SPECIFICATIONS are presented in boldface text throughout the manual. The specifications are also found in the "Service Specifications" section for reference.

6. TERM DEFINITIONS

7. INTERNATIONAL SYSTEM OF UNITS

(a) The units used in this manual comply with the International System of Units (SI UNIT) standard.

Units from the metric system and the English systems are also provided.

Example:

Torque: 30 N*m (310 kgf*cm, 22 ft.*lbf)

Introduction

Introduction

...

Identification information

Identification information

VEHICLE IDENTIFICATION AND SERIAL NUMBERS

1. VEHICLE IDENTIFICATION NUMBER

(a) The vehicle identification number is stamped on the

vehicle identification number plate and the

certification label, ...

Other materials:

Master Reset/ Voice Processing Device ON Error

DTC 01-DD Master Reset

DTC 01-E1 Voice Processing Device ON

DESCRIPTION

DTC No.

DTC Detection Condition

Trouble Area

01-DD

*1

The device that should be the master has been

disconnected after the engine starts.

Radio and navigation assembly po ...

Inspection

1. INSPECT CHARCOAL CANISTER ASSEMBLY

(a) Visually check the charcoal canister for cracks or

damage.

If cracks or damage are found, replace the charcoal

canister assembly.

(b) Check charcoal canister operation.

(1) With the purge port closed, blow 1.67 kPa (17.0

gf/cm2, 0.24 psi) ...

CD Abnormal/ Excess Current/ Tray Insertion / Ejection Error

DTC 63-44 CD Abnormal

DTC 63-48 Excess Current

DTC 63-50 Tray Insertion / Ejection Error

DESCRIPTION

DTC No.

DTC Detection Condition

Trouble Area

63-44

Operation error in the CD mechanism

Radio and navigation assembly

63-48

Excess current is pr ...