Toyota Sienna Service Manual: Initialization

1. ZERO POINT CALIBRATION

NOTICE: Make sure that the front passenger seat is not occupied before performing the operation.

HINT: Perform the zero point calibration and sensitivity check if any of the following conditions occur.

- The occupant classification ECU is replaced.

- Accessories (seatback tray and seat cover, etc.) are installed.

- The front passenger seat is removed from the vehicle.

- The passenger airbag ON/OFF indicator ("OFF") comes on when the front passenger seat is not occupied.

- The vehicle is brought to the workshop for repair due to an accident or a collision.

- Zero point calibration and sensitivity check procedures

HINT: Make sure that zero point calibration has finished normally, and then perform the sensitivity check.

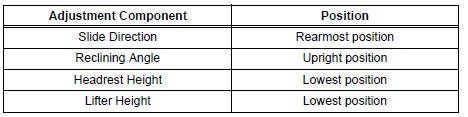

- Adjust the seat position according to the table below.

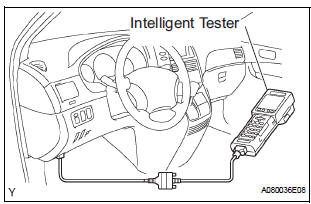

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

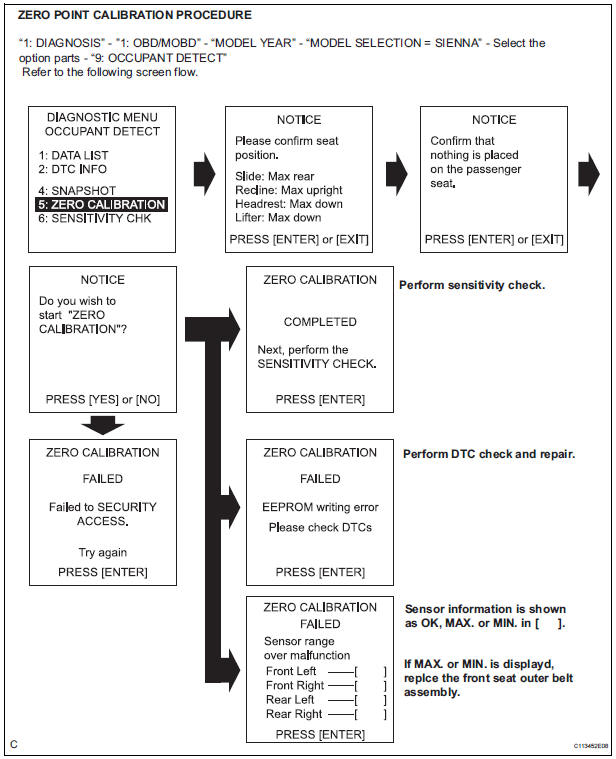

- Perform the zero point calibration by following the prompts on the tester screen.

HINT: Refer to the intelligent tester operator's manual for further details.

OK: "COMPLETE" is displayed.

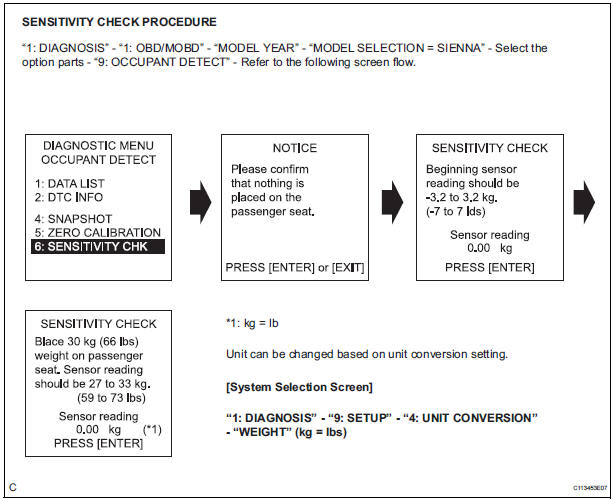

- Perform the sensitivity check by following the prompts on the tester screen.

- Confirm that the beginning sensor reading is

within the standard range.

Standard value: -3.2 to 3.2 kg (-7 to 7 lb)

- Place a 30 kg (66.14 lb) weight (eg. a 30 kg (66.14 lb) of lead mass) onto the front passenger seat.

- Confirm that the sensitivity is within the standard range.

Standard value: 27 to 33 kg (59.52 to 72.75 lb)

HINT:

- When performing the sensitivity check, use a solid metal weight (the check result may not appear properly if a liquid weight is used).

- If the sensitivity deviates from the standard range, retighten the bolts of the front passenger seat taking care not to deform the seat rail. After performing this procedure, if the sensitivity is not within the standard range, replace the front seat assembly RH.

- If zero point calibration has not finished normally, replace the front seat assembly RH.

How to proceed with

troubleshooting

How to proceed with

troubleshooting

The intelligent tester can be used in steps 4, 6, 8 and 9.

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS

3 PASSENGER AIRBAG ON/OFF INDICATOR CHECK

4 DTCs CHECK (Present and Past DTCs)

...

Problem symptoms table

Problem symptoms table

HINT:

Proceed to the troubleshooting for each circuit in the table

below.

Occupant Classification System

Symptom

Suspected area

The front passenger seat condition differ ...

Other materials:

Short to GND in Front Passenger Side Squib

Circuit

DTC B0107/51 Short to GND in Front Passenger Side Squib

Circuit

DESCRIPTION

The front passenger side squib circuit consists of the center airbag sensor

assembly and the front

passenger airbag assembly.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0107/ ...

Installation

1. INSTALL BRAKE ACTUATOR

(a) Install the brake actuator assembly with the 2 nuts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

2. INSTALL BRAKE ACTUATOR WITH BRACKET

(a) Install the actuator with bracket with the 3 bolts.

Torque: 20 N*m (199 kgf*cm, 14 ft.*lbf)

NOTICE:

Be careful not to dam ...

Open in Side Squib RH Circuit

DTC B0111/44 Open in Side Squib RH Circuit

DESCRIPTION

The side squib RH circuit consists of the center airbag sensor assembly and

the front seat side airbag

assembly RH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0111/44 is recorded when an open circ ...