Toyota Sienna Service Manual: Inspection

1. INSPECT TIRES

(a) Check the tires for wear and proper inflation pressure.

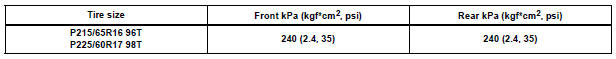

Cold tire inflation pressure

(b) Using a dial indicator, check the runout of the tires.

Tire runout: 1.4 mm (0.055 in.) or less

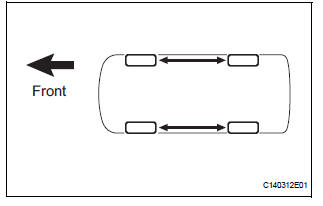

2. ROTATE TIRES

HINT: Rotate the tires as shown in the illustration.

3. INSPECT WHEEL BALANCE (for Steel Wheel)

(a) Check and adjust the off-the-car balance.

Imbalance after adjustment: 8.0 g (0.018 lb.) or less.

HINT: If necessary, check and adjust the on-the-car balance.

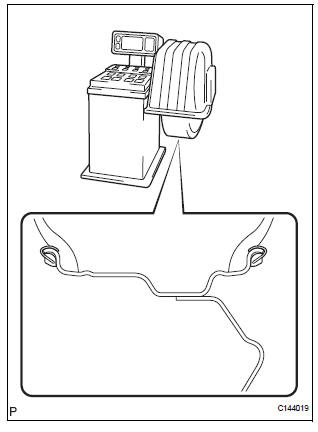

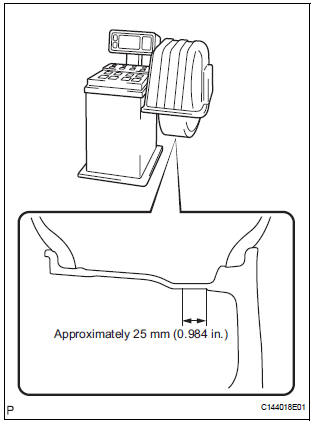

4. INSPECT WHEEL BALANCE (for Non-steel Wheel)

(a) Check and adjust the off-the-car balance.

Imbalance after adjustment: 8.0 g (0.018 lb.) or less.

NOTICE:

- Use a cleaning detergent to remove dirt, oil and water from the surface where the balance weight is to be adhered.

- Do not touch the sticking surface of the tape.

- Adhere the sticking type balance weight to the flat position shown in the illustration.

- Push the balance weight securely with a finger to adhere it to the position.

- Do not reuse the balance weight.

HINT:

- The inner side balance weight should be installed by clipping it to the rim.

- If necessary, check and adjust the on-the-car balance.

5. INSPECT FRONT AXLE HUB BEARING LOOSENESS

HINT: See page AH-5.

6. INSPECT REAR AXLE HUB BEARING LOOSENESS (for 2WD)

HINT: See page AH-16.

7. INSPECT REAR AXLE HUB BEARING LOOSENESS (for 4WD)

HINT: See page AH-19.

8. INSPECT FRONT AXLE HUB RUNOUT

HINT: See page AH-5.

9. INSPECT REAR AXLE HUB RUNOUT (for 2WD)

HINT: See page AH-16.

10. INSPECT REAR AXLE HUB RUNOUT (for 4WD)

HINT: See page AH-19.

Problem symptoms table

Problem symptoms table

HINT:

Use the table below to help determine the cause of the

problem. The likely causes of the problem are indicated in

descending order. Check each suspected area in order. If

necessary, repair o ...

Repair

Repair

1. INTRODUCTION

(a) This section introduces ways to determine whether

the run-flat tire is repairable or not. Repair must be

performed by following the appropriate procedures.

If a flat tire occ ...

Other materials:

Stereo component amplifier

COMPONENTS

Removal

1. REMOVE GLOVE COMPARTMENT DOOR ASSEMBLY

2. REMOVE STEREO COMPONENT AMPLIFIER ASSEMBLY

Disconnect the connectors.

Remove the 2 nuts and the stereo component

amplifier assembly.

Installation

1. INSTALL STEREO COMPONENT AMPLIFIER ASSEMBLY

...

Magnetic clutch relay

ON-VEHICLE INSPECTION

1. INSPECT MAGNETIC CLUTCH RELAY

(a) Remove the magnetic clutch relay.

(b) Measure the resistance according to the value(s) in

the table below.

Standard resistance

If the resistance is not as specified, replace the

magnetic clutch relay. ...

Open in Driver Side Squib Circuit

DTC B0101/14 Open in Driver Side Squib Circuit

DESCRIPTION

The driver side squib circuit consists of the center airbag sensor assembly,

the spiral cable and the

steering pad.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0101/14 is recorded when an open ...