Toyota Sienna Service Manual: Repair

1. INTRODUCTION

(a) This section introduces ways to determine whether the run-flat tire is repairable or not. Repair must be performed by following the appropriate procedures.

If a flat tire occurs, it is possible to drive a maximum of 160 km (100 miles) at a speed below 90 km/h (55 mph) due to the reinforced sidewalls. However, if the customer continues to drive with low tire pressure (less than about 100 kPa (1.0 kgf/cm2, 14.5 psi) and tire pressure warning light is on), the inside of the sidewall will gradually deteriorate and the run-flat performance may be reduced.

Therefore, the tires may require replacement.

However, there are some cases where it is possible to repair a run-flat tire using the same repair method as for normal tires. Use the following flowchart to determine if a run-flat tire is repairable.

NOTICE: When performing repairs, follow the Rubber Manufacturers Association (RMA) repair procedures.

2. REPAIR PROCEDURE (CUSTOMER INTERVIEW)

(a) The tire pressure warning system can help determine the history of the tire's use. The driving conditions the tire was subjected to while the tire pressure warning light was on should be obtained from the customer. Also, make sure to ask the following questions.

(1) Was the vehicle driven at a speed over 90 km/h (55 mph) with the tire pressure warning light on? (2) Was the vehicle driven over 160 km (100 miles) with the tire pressure warning light on? A "Yes" response to either of the above will greatly reduce the chance of tire repairability.

3. TECHNICIAN TIRE INSPECTION

(a) After the customer interview, it is necessary to conduct a thorough inspection of the tire after it has been removed from the wheel. As it is difficult to identify a tire with low pressure visually, check the pressure of each tire to determine the tire(s) causing the low-pressure warning. If the tire is found to be repairable, follow the RMA repair procedures.

NOTICE: The deflated tire may be extremely hot, which may cause injury, so allow the tire to cool prior to handling.

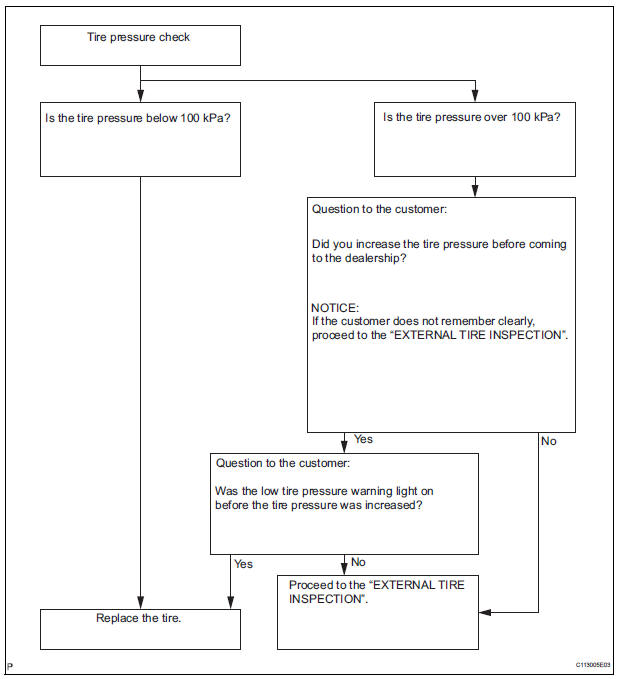

4. TIRE PRESSURE INSPECTION

(a) Inspection procedure

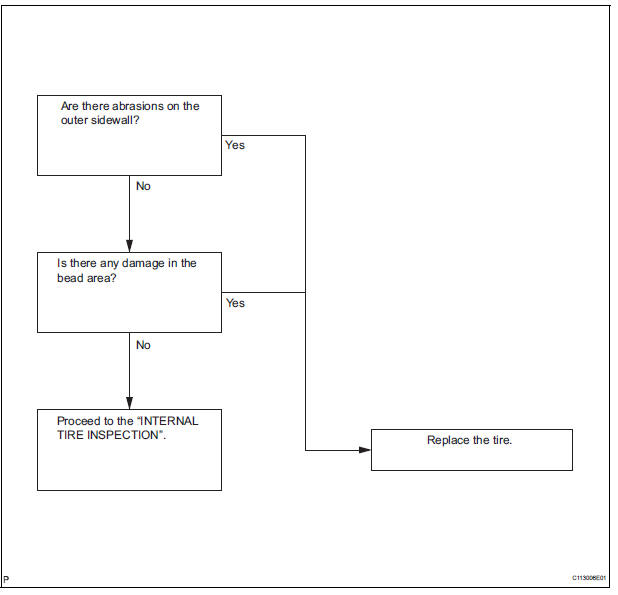

5. EXTERNAL TIRE INSPECTION

(a) Inspection procedure

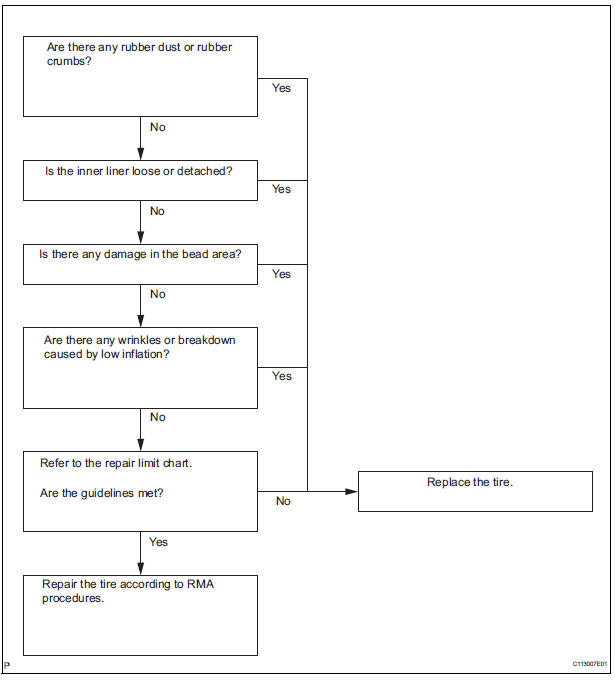

6. INTERNAL TIRE INSPECTION

(a) Inspection procedure

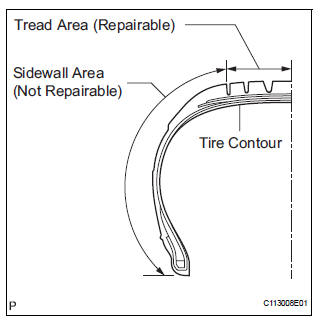

7. RUN-FLAT TIRE REPAIR LIMIT CHART

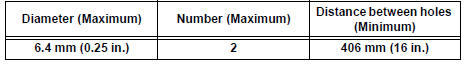

(a) Tires that have a penetration in the tread area but meet the above inspection criteria may be repaired if the guidelines listed below are also met.

Puncture condition (Tread area only)

Inspection

Inspection

1. INSPECT TIRES

(a) Check the tires for wear and proper inflation

pressure.

Cold tire inflation pressure

(b) Using a dial indicator, check the runout of the tires.

Tire runout:

1.4 mm (0.0 ...

Other materials:

Ambient temperature sensor

ON-VEHICLE INSPECTION

1. INSPECT A/C AMBIENT TEMPERATURE SENSOR

(a) Remove the A/C ambient temperature sensor.

(b) Disconnect the connector from A/C ambient

temperature sensor.

(c) Measure the resistance according to the value(s) in

the table below.

Standard resistance

NOTICE:

E ...

Disposal

1. DISPOSE OF FRONT SEAT OUTER BELT ASSEMBLY (WHEN INSTALLED IN VEHICLE)

NOTICE:

Never dispose of a front seat outer belt assembly

with an deactivated pretensioner.

The seat belt pretensioner produces an exploding

sound when it activates, so perform the operation

outdoors wh ...

Short to B+ in Rear Curtain Shield Squib RH

Circuit

DTC B1633/82 Short to B+ in Rear Curtain Shield Squib RH

Circuit

DESCRIPTION

The rear curtain shield squib RH circuit consists of the center airbag sensor

assembly and the curtain

shield airbag assembly RH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B ...