Toyota Sienna Service Manual: Installation

1. INSTALL BRAKE ACTUATOR

(a) Install the brake actuator assembly with the 2 nuts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

2. INSTALL BRAKE ACTUATOR WITH BRACKET

(a) Install the actuator with bracket with the 3 bolts.

Torque: 20 N*m (199 kgf*cm, 14 ft.*lbf)

NOTICE: Be careful not to damage the brake tubes and wire harness.

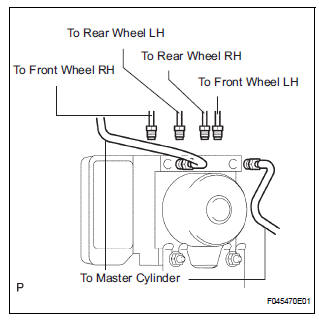

(b) Using SST, connect each brake tube to correct positions of the actuator with bracket, as shown in the illustration.

Torque: 15 N*m (155 kgf*cm, 11 ft.*lbf)

(c) Connect the brake actuator connector assembly.

3. INSTALL AIR CLEANER ASSEMBLY WITH HOSE

4. FILL RESERVOIR WITH BRAKE FLUID (See page BR- 3)

5. BLEED BRAKE MASTER CYLINDER SUBASSEMBLY (See page BR-3)

6. BLEED BRAKE LINE (See page BR-4)

7. CHECK BRAKE FLUID LEAKAGE

8. CHECK FLUID LEVEL IN RESERVOIR (See page BR- 7)

9. CONNECT BATTERY NEGATIVE TERMINAL

10. PERFORM INITIALIZATION

11. CHECK BRAKE ACTUATOR WITH INTELLIGENT TESTER

HINT: See page BC-183.

Removal

Removal

1. DRAIN BRAKE FLUID

NOTICE:

Wash brake fluid off immediately if it adheres to any

painted surface.

2. DISCONNECT BATTERY NEGATIVE TERMINAL

3. REMOVE AIR CLEANER ASSEMBLY WITH HOSE

4. REMOVE BRA ...

Other materials:

Removal

1. REMOVE REAR WHEEL

2. REMOVE SKID CONTROL SENSOR WIRE (for 2WD)

(a) Disconnect the skid control sensor connector.

(b) Remove the bolt and disconnect the bracket from

the rear axle beam assembly.

HINT:

Separate the RH side by the same procedures as

the LH side.

3. SEPARATE SPEED SENSO ...

Installation

1. Install air fuel ratio sensor (for bank 2

sensor 1)

(a) Using SST, install the sensor to the exhaust

manifold LH.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

Use a torque wrench with a fulcrum ...

Power Seat Motor Circuit

DESCRIPTION

When the power seat control switch is operated, a command signal is sent to

the position control ECU

and switch assembly (power seat control switch and ECU). The front power seat

switch then controls the

appropriate seat motor as needed. This memory system does not use a seat

po ...