Toyota Sienna Service Manual: Installation

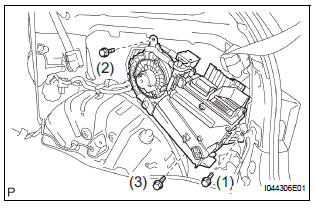

1. INSTALL AIR CONDITIONING BLOWER ASSEMBLY

(a) Install the air conditioning blower assembly with the 3 bolts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

NOTICE: Tighten the bolts in the order shown in the illustration to install the air conditioning blower assembly.

2. INSTALL AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY

(a) Sufficiently apply compressor oil to 2 new O-rings and the fitting surface of the air conditioning tube & accessory assembly.

Compressor oil: ND-OIL 8 or equivalent

(b) Install the 2 O-rings on the air conditioning tube & accessory assembly.

(c) Install the air conditioning tube & accessory assembly with the 2 bolts.

Torque: 3.5 N*m (36 kgf*cm, 31 in.*lbf)

3. ADD ENGINE COOLANT

HINT: See page CO-7.

4. CHARGE REFRIGERANT

SST 07110-58060 (07117-58060, 07117-58070, 07117-58080, 07117-58090, 07117-78050, 07117-88060, 07117-88070, 07117-88080)

HINT: See page AC-172.

5. WARM UP ENGINE

6. INSPECT FOR ENGINE COOLANT LEAK

HINT: See page CO-1.

7. INSPECT REFRIGERANT LEAK

HINT: See page AC-168.

Reassembly

Reassembly

1. INSTALL HEATER RADIATOR UNIT SUB-ASSEMBLY

(a) Install the heater radiator unit sub-assembly to the

air conditioning blower assembly.

(b) Install the 2 O-rings to the heater water valve

as ...

Blower motor

Blower motor

On-vehicle inspection

1. INSPECT BLOWER WITH FAN MOTOR SUBASSEMBLY

(a) Connect the positive (+) lead from the battery to

terminal 2 and negative (-) to terminal 1, then check

that the motor op ...

Other materials:

Stowing the third seats (manual seats)

Before stowing or returning third seat, remove any items from the floor

area to prevent interference with moving parts.

Before stowing the third seats

Lower the center head

restraint to the lowest position

, and stow the

seat belt buckles.

Stow the center seat belt.

Stowing ...

Reassembly

1. INSTALL LH REAR BUMPER SIDE RETAINER

Install the LH rear bumper side retainer with the 3

screws.

2. INSTALL RH REAR BUMPER SIDE RETAINER

Install the RH rear bumper side retainer with the 3

screws.

3. INSTALL REAR BUMPER REINFORCEMENT SUBASSEMBLY

Install the rear bumper reinf ...

Transmission Fluid Temperature Sensor "A"

DESCRIPTION

The ATF (Automatic Transmission Fluid) temperature sensor converts the fluid

temperature into a

resistance value which is input into the ECM.

The ECM applies a voltage to the temperature sensor through ECM terminal THO1.

The sensor resistance changes with the transmission f ...