Toyota Sienna Service Manual: Installation

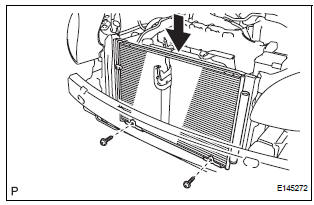

1. INSTALL COOLER CONDENSER CORE

(a) Install the cooler condenser core with the 2 screws.

Torque: 3.9 N*m (40 kgf*cm, 35 in.*lbf)

HINT: If the condenser is replaced with a new one, add compressor oil to the new condenser.

Capacity: 40 cc (1.4 fl.oz.) Compressor oil: ND-OIL 8 or equivalent

2. INSTALL NO. 1 RADIATOR SUPPORT (See page CO- 40)

3. INSTALL RADIATOR SUPPORT CUSHION (See page CO-41)

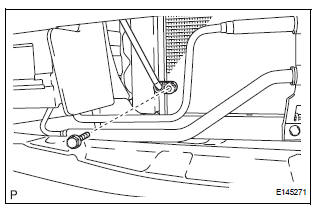

4. CONNECT NO. 2 OIL COOLER OUTLET TUBE SUBASSEMBLY

(a) Install the No. 2 oil cooler outlet tube sub-assembly with the 2 bolts.

Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

5. INSTALL UPPER RADIATOR SUPPORT SUBASSEMBLY (See page CO-42)

6. CONNECT COOLING FAN ECU (See page CO-42)

7. INSTALL HOOD LOCK SUPPORT SUB-ASSEMBLY (See page CO-43)

8. INSTALL HOOD LOCK ASSEMBLY (See page CO-43)

9. INSTALL HOOD LOCK RELEASE LEVER PROTECTOR (See page CO-44)

10. INSTALL NO. 1 AIR CLEANER INLET (See page EM- 59)

11. INSTALL COOLER REFRIGERANT LIQUID PIPE A

(a) Remove the attached vinyl tape from the pipe and the connecting part of the cooler condenser core.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the pipe joint.

Compressor oil: ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant liquid pipe A.

(d) Install the cooler refrigerant liquid pipe A on the cooler condenser core with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 47 in.*lbf)

12. INSTALL DISCHARGE HOSE SUB-ASSEMBLY

(a) Remove the attached vinyl tape from the tube and the connecting part of the cooler condenser core.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the hose joint.

Compressor oil: ND-OIL 8 or equivalent

(c) Install the O-ring on the discharge hose subassembly.

(d) Install the discharge hose sub-assembly on the cooler condenser core with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 47 in.*lbf)

13. INSTALL FRONT BUMPER ASSEMBLY (See page ET- 9)

14. INSTALL NO. 2 AIR CLEANER INLET (See page EM- 60)

15. CHARGE WITH REFRIGERANT (See page AC-173)

16. WARM UP ENGINE

17. INSPECT FOR REFRIGERANT LEAK (See page AC- 173)

18. VEHICLE PREPARATION FOR FOG LIGHT AIMING (w/ Fog Light) (See page LI-82)

19. PREPARATION FOR FOG LIGHT AIMING (w/ Fog Light) (See page LI-83)

20. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See page LI-84)

21. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light) (See page LI-85)

Reassembly

Reassembly

1. INSTALL COOLER DRYER

(a) Using needle nose pliers, install the cooler dryer.

(b) Install a new O-ring on the cap.

(c) Sufficiently apply compressor oil to the fitting

surfaces of the ...

Room temperature sensor

Room temperature sensor

On-vehicle inspection

1. INSPECT A/C ROOM TEMPERATURE SENSOR

(a) Remove the A/C room temperature sensor.

(b) Measure the resistance according to the value(s) in

the table below.

Standard re ...

Other materials:

Problem symptoms table

When a "Normal" code is output during a DTC check but

the problem still occurs, use the Problem Symptoms

Table. The suspected areas (circuits or parts) for each

problem symptoms are in the table. The suspected areas

are listed in order of probability. A description of each of

the char ...

Removal and installation of engine intake parts

REMOVAL AND INSTALLATION OF ENGINE INTAKE PARTS

(a) If any metal particles enter inlet system parts, this

may damage the engine.

(b) When removing and installing inlet system parts,

cover the openings of the removed parts and engine

openings. Use gummed tape or other suitable

materials ...

Installation

1. INSTALL TIRE PRESSURE WARNING VALVE AND TRANSMITTER

(a) Insert the tire pressure warning valve and

transmitter into the valve installation hole. Insert it

from the inside of the rim so that the printed surface

can be seen.

NOTICE:

Check that there is no visible deformation,

damage, ...