Toyota Sienna Service Manual: Lubrication system

On-vehicle inspection

1. CHECK ENGINE OIL LEVEL

(a) Warm up the engine, stop it and wait 5 minutes. The oil level should be between the dipstick's low level mark and full level mark.

If the engine oil level is low, check for leakage and add oil up to the full level mark.

| NOTICE: Do not add engine oil above the full level mark. |

2. CHECK ENGINE OIL

(a) Check the engine oil for deterioration, water contamination, discoloring or thinning.

If the oil is bad, replace the engine oil and engine oil filter.

3. CHECK OIL PRESSURE

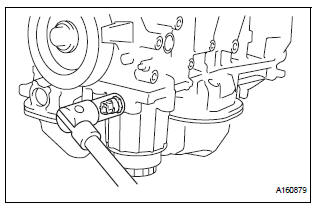

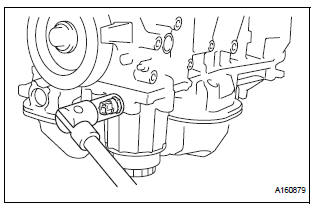

(a) Disconnect the oil pressure switch connector.

(b) Using a 24 mm deep socket wrench, remove the oil pressure switch.

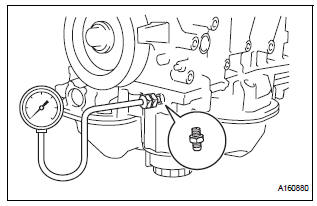

(c) Install the oil pressure gauge with adapter.

(d) Warm up the engine.

(e) Check the oil pressure.

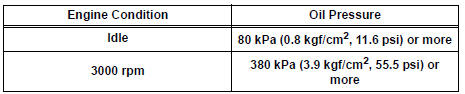

Standard oil pressure

If the oil pressure is not as specified, check the oil pump (See page LU-13).

(f) Remove the oil pressure gauge.

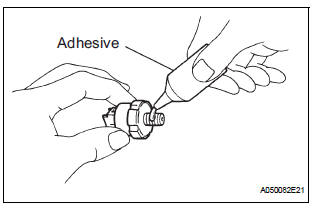

(g) Apply adhesive to 2 or 3 threads of the oil pressure switch.

Adhesive: Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

(h) Using a 24 mm deep socket wrench, install the oil pressure switch.

Torque: 15 N*m (153 kgf*cm, 11 ft.*lbf)

| NOTICE: Do not start the engine within 1 hour after installation. |

(i) Connect the oil pressure switch connector.

(j) Check for engine oil leaks.

Oil and oil filter

Oil and oil filter

COMPONENTS

REPLACEMENT

CAUTION:

Prolonged and repeated contact with engine oil will

result in the removal of natural oils from the skin,

leading to dryness, irritation and derma ...

Other materials:

Display check mode

HINT:

This mode checks the color display on the display.

Illustrations may differ from the actual vehicle depending

on the device settings and options. Therefore, some

detailed areas may not be shown exactly the same as on

the actual vehicle.

1. ENTER DIAGNOSTIC MODE

2. D ...

Data list / active test

1. DATA LIST

(a) While the intelligent tester is connected to the DLC3

with the ignition switch in the ON position, the ABS

data list can be displayed. Follow the prompts on

the tester screen to access the DATA LIST.

2. ACTIVE TEST

HINT:

Performing the ACTIVE TEST using the intelligent te ...

Terminals of ECU

1. CHECK DISTANCE CONTROL ECU

Reference: waveform 1

HINT:

Terminal: LRDD - SGND

Gauge set: 2 V/DIV., 10 ms./DIV.

Condition: ignition switch in the ON position

Reference: waveform 2

HINT:

Terminal: LRRD - SGND

Gauge set: 2 V/ ...