Toyota Sienna Service Manual: Shift lock system

On-vehicle inspection

1. CHECK SHIFT LOCK OPERATION

(a) Move the shift lever to the P position.

(b) Turn the ignition switch to the LOCK position.

(c) Check that the shift lever cannot be moved to any position other than P.

(d) Turn the ignition switch to the on position, depress the brake pedal and check that the shift lever can be moved to another position. If operation can not be done as specified, inspect the shift lock control unit.

2. CHECK SHIFT LOCK RELEASE BUTTON OPERATION

(a) Using a small screwdriver, remove the shift lock release cover.

(b) When operating the shift lever with the shift lock release button pressed, check that the lever can be moved to any position other than P.

If operation can not be done as specified, check the shift lever assembly installation condition.

3. CHECK KEY INTERLOCK OPERATION

(a) Turn the ignition switch to the ON position.

(b) Depress the brake pedal and move the shift lever to any position other than P.

(c) Check that the ignition key cannot be turned to the LOCK position.

(d) Move the shift lever to the P position, turn the ignition key to the LOCK position and check that the ignition key can be removed.

If operation cannot be done as specified, inspect the shift lock control unit.

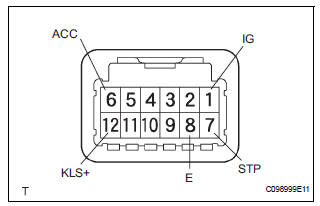

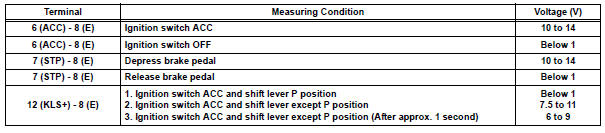

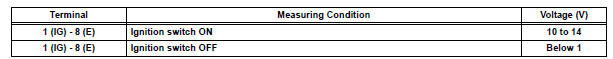

4. INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY

(a) Measure the voltage according to the value(s) in the table below.

HINT: Do not disconnect the shift lock control unit assembly connector.

Voltage

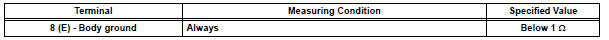

(b) Measure the resistance according to the value(s) in the table below.

HINT: Do not disconnect the shift lock control unit assembly connector.

If operation cannot be done as specified, replace the shift lever assembly.

Resistance

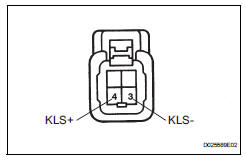

5. INSPECT KEY INTER LOCK SOLENOID

(a) Disconnect the solenoid connector.

(b) Connect KLS+ (4) terminal to the batteries' positive (+) terminal and KLS (3) terminal to the battery negative (-) terminal, and apply about 12 V between KLS+ - KLS- terminals.

(c) Check that operation noise can be heard from the solenoid.

If the solenoid does not operate, replace the solenoid.

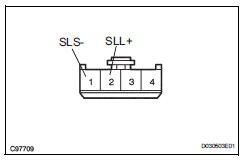

6. INSPECT SHIFT LOCK SOLENOID

(a) Disconnect the solenoid connector.

(b) Connect SSL+ (2) terminal to the batteries' positive (+) terminal, and SLS- (1) terminal to the battery negative (-) terminal, and apply about 12 V between SLL+-SLS- terminals.

(c) Check that operation noise can be heard from the solenoid.

If the solenoid does not operate, replace the solenoid.

Installation

Installation

1. Install transmission valve body assembly

(a) Install the shift solenoid valve SL1 to the valve body

assembly with the bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(b) Install the shi ...

Shift lever

Shift lever

Components

...

Other materials:

Short to B+ in Curtain Shield Squib RH Circuit

DTC B1163/82 Short to B+ in Curtain Shield Squib RH Circuit

DESCRIPTION

The curtain shield squib RH circuit consists of the center airbag sensor

assembly and the curtain shield

airbag assembly RH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B1163/82 is ...

Open in One Side of CAN Branch Line

DESCRIPTION

If 2 or more ECUs and/or sensors do not appear on the intelligent tester

"Communication Bus Check"

screen, one side of the CAN branch wire may be open. (One side of the CAN-H

[branch wire] / CAN-L

[branch wire] of the ECU and/or sensor is open.)

Symptom

...

Installation

1. INSTALL RADIO NO. 2 BRACKET

Install radio No. 2 bracket with the 4 screws.

2. INSTALL RADIO NO. 1 BRACKET

Install radio No. 1 bracket with the 4 screws.

3. INSTALL RADIO RECEIVER

Connect the connector.

Install the radio receiver with the 4 scr ...