Toyota Sienna Service Manual: Installation

1. Install transmission valve body assembly

(a) Install the shift solenoid valve SL1 to the valve body assembly with the bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(b) Install the shift solenoid valve SL2 to the valve body assembly with the bolt.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

(c) Install the shift solenoid valve DSL to the valve body assembly with the bolt.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

(d) Install the shift solenoid valve SR to the valve body assembly.

(e) Install the shift solenoid valve S4 to the valve body assembly with the bolt.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

(f) Install the shift solenoid valve SL3 and SLT to the valve body assembly.

(g) Install the lock plate to the valve body assembly with the bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(h) Install the spring and check ball body.

(i) Align the groove of the manual valve with the pin of the lever.

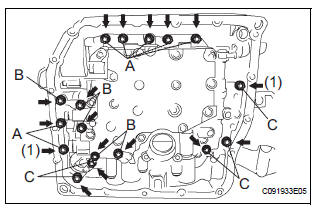

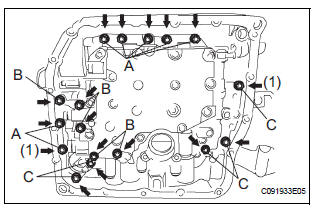

(j) Install the 17 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

(i) Align the groove of the manual valve with the pin of the lever.

(j) Install the 17 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

NOTICE:

|

Bolt length: Bolt A: 41 mm (1.614 in.) Bolt B: 57 mm (2.244 in.) Bolt C: 25 mm (0.984 in.)

2. INSTALL VALVE BODY OIL STRAINER ASSEMBLY

(a) Coat a new O-ring with ATF.

(b) Install the O-ring to the oil strainer.

(c) Install the oil strainer with the 3 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

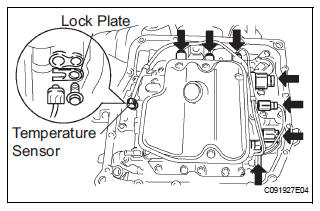

3. INSTALL TRANSMISSION WIRE

(a) Coat the O-ring with ATF.

(b) Install the ATF temperature sensor with the lock plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf) (c) Connect the 7 shift solenoid valve connectors.

4. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUBASSEMBLY

(a) Install the 2 magnets in the oil pan.

(b) Apply seal packing or equivalent to the 18 bolts.

Seal packing: THREE BOND 2430 or equivalent

(c) Install the oil pan and new gasket with the 18 bolts to the transaxle case.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

| NOTICE: Tighten the bolts within 10 minutes of sealant application. |

5. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL 6. ADD AUTOMATIC TRANSAXLE FLUID 7. CHECK FLUID LEVEL IN AUTOMATIC TRANSAXLE (See page AX-123) 8. INSTALL ENGINE UNDER COVER NO.1 9. RESET MEMORY

HINT: (See page AX-16)

Removal

Removal

1. Remove engine under cover no.1

2. Disconnect cable from negative battery

terminal

3. Drain automatic transaxle fluid (see page

ax-131)

4. Remove automatic transaxle oil pan subassembly

(a ...

Shift lock system

Shift lock system

On-vehicle inspection

1. CHECK SHIFT LOCK OPERATION

(a) Move the shift lever to the P position.

(b) Turn the ignition switch to the LOCK position.

(c) Check that the shift lever cannot be move ...

Other materials:

Terminals of ECU

1. CENTER AIRBAG SENSOR ASSEMBLY (w/ Side

Airbag)

2. CENTER AIRBAG SENSOR ASSEMBLY (w/o Side

Airbag)

...

Removal

1. REMOVE REAR SEAT 3 POINT TYPE BELT

ASSEMBLY (for 8-Passenger)

HINT:

Refer to the instructions for disassembly of the rear No. 1

seat assembly (for center seat).

Remove the bolt and rear seat 3 point type belt

assembly.

2. REMOVE REAR SEAT 3 POINT TYPE BELT

ASSEMBLY (for 7-Pass ...

Installation

1. INSTALL REAR AXLE HUB & BEARING ASSEMBLY LH

(a) Install the hub & Bearing assembly LH with the 4

bolts.

Torque: 56 N*m (571 kgf*cm, 41 ft.*lbf)

2. INSPECT BEARING BACKLASH (See page AH-16)

3. INSPECT AXLE HUB DEVIATION (See page AH-16)

4. CONNECT SKID CONTROL SENSOR WIRE

(a) Co ...