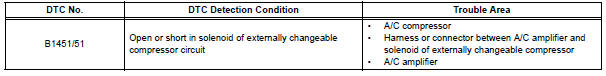

Toyota Sienna Service Manual: Compressor Solenoid Circuit

DESCRIPTION

In this circuit, the compressor receives a refrigerant compression demand signal from the A/C amplifier.

Based on this signal, the compressor changes the amount of compressor output.

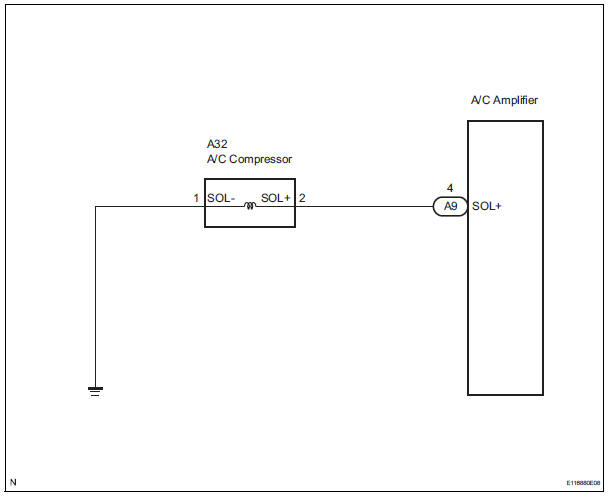

WIRING DIAGRAM

INSPECTION PROCEDURE

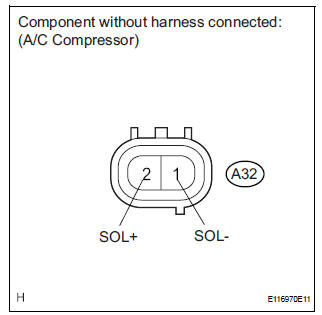

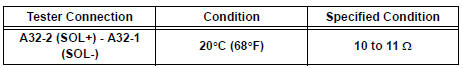

1 INSPECT A/C COMPRESSOR

(a) Disconnect the A/C compressor connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

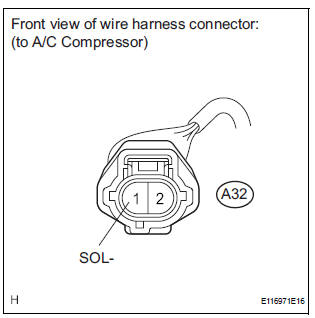

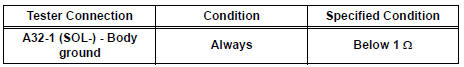

2 CHECK HARNESS AND CONNECTOR (A/C COMPRESSOR - BODY GROUND)

(a) Disconnect the A/C compressor connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

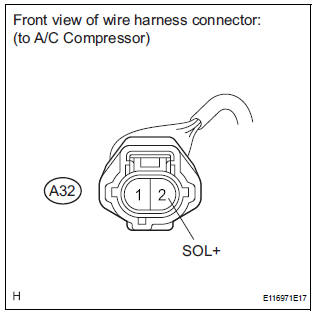

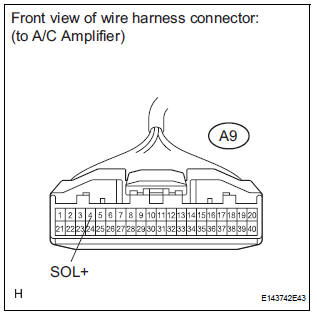

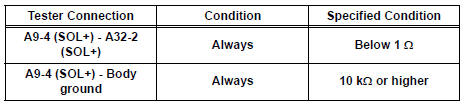

3 CHECK HARNESS AND CONNECTOR (A/C COMPRESSOR - A/C AMPLIFIER)

(a) Disconnect the A/C compressor connector.

(b) Disconnect the A/C amplifier connector.

(c) Measure the resistance according to the value(s) in the table below

Standard resistance

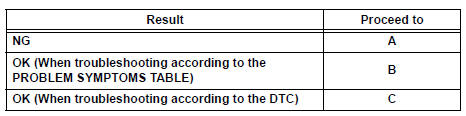

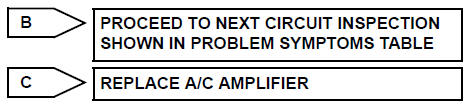

Result

REPAIR OR REPLACE HARNESS OR CONNECTOR

Rear Air Outlet Damper Control Servo Motor Circuit

Rear Air Outlet Damper Control Servo Motor Circuit

DESCRIPTION

This circuit turns the servo motor and changes each damper position by

receiving the signals from the A/

C amplifier.

The rear air outlet damper servo motor switches the air outlet ...

Multiplex Communication Circuit

Multiplex Communication Circuit

DESCRIPTION

INSPECTION PROCEDURE

1 GO TO CAN COMMUNICATION SYSTEM

(a) Refer to the CAN communication system (See page CA-

7).

(b) If the CAN communication system is operating normally,

procee ...

Other materials:

Installation

1. INSTALL SEAT MEMORY SWITCH

2. INSTALL FRONT DOOR TRIM BOARD SUBASSEMBLY

LH

3. INSTALL POWER WINDOW REGULATOR MASTER

SWITCH ASSEMBLY

4. INSTALL FRONT DOOR INSIDE HANDLE BEZEL

PLUG LH

5. INSTALL FRONT DOOR LOWER FRAME BRACKET GARNISH LH

Engage the 4 claws to install the seat me ...

Identification of noise source

1. Radio Description

Radio frequency band

Radio broadcasts use the radio frequency bands

shown in the table below.

Service area

The service areas of AM and FM broadcasts are

vastly different. Sometimes an AM broadcast

can be received very clearly ...

Removal

HINT:

On the RH side, use the same procedures as on the LH side.

1. REMOVE BACK DOOR STAY SUB-ASSEMBLY LH

Remove the 2 bolts and disconnect the stay from

the body panel.

Using the screwdriver, disengage the clips and

remove the stay from the door panel.

Remove the bolt from door pa ...