Toyota Sienna Service Manual: Rear Air Outlet Damper Control Servo Motor Circuit

DESCRIPTION

This circuit turns the servo motor and changes each damper position by receiving the signals from the A/ C amplifier.

The rear air outlet damper servo motor switches the air outlet mode by rotating

(normal, reverse) with

electrical power from the A/C amplifier.

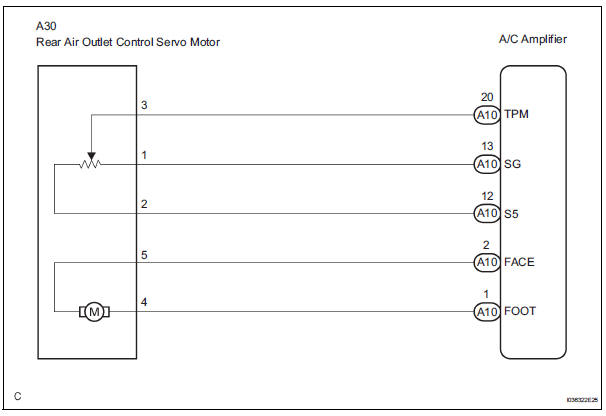

WIRING DIAGRAM

INSPECTION PROCEDURE

1 READ VALUE OF INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the items below in the DATA LIST, and read the display on the intelligent tester.

DATA LIST / AIR CONDITIONER

OK: When the target position is "FACE1" (0%), the actual opening angle is 19.0% or less.

When the target position is "FOOT" (100%), the actual opening angle is 81.0% or more.

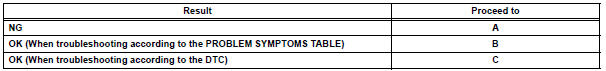

Result

2 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the item below in the ACTIVE TEST and then check the air flow position by hand.

ACTIVE TEST / AIR CONDITIONER

OK: Air comes out from the selected air outlet.

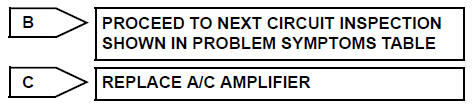

Result

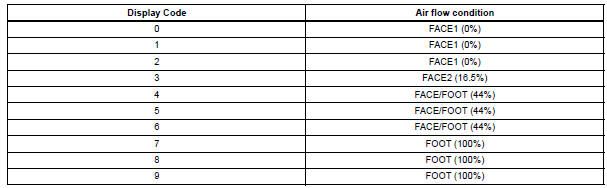

3 PERFORM ACTUATOR CHECK

(a) Warm up the engine.

(b) Enter the actuator check mode (See page AC-15).

(c) Press the DEF switch and change to step operation.

(d) Press the DEF switch and check the air flow by hand.

OK: Air outlet mode changes in accordance with each display code.

Result

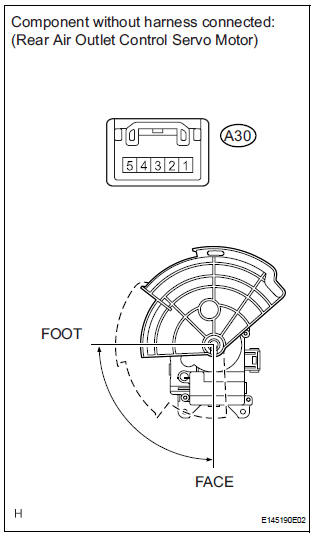

4 INSPECT REAR AIR OUTLET CONTROL SERVO MOTOR

(a) Remove the rear air outlet control servo motor.

(b) Disconnect the connector from the rear air outlet control servo motor.

(c) Connect the positive (+) lead from the battery to terminal 4 and the negative (-) lead to terminal 5, then check that the lever turns to the "FOOT" position smoothly.

OK: Lever turns to "FOOT" position smoothly.

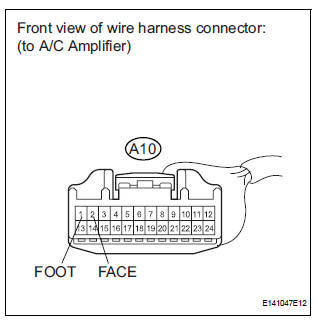

5 CHECK HARNESS AND CONNECTOR (REAR AIR OUTLET CONTROL SERVO MOTOR - A/C AMPLIFIER)

(a) Disconnect the connector from the A/C amplifier.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE A/C AMPLIFIER

Rear Air Mix Damper Control Servo Motor Circuit

Rear Air Mix Damper Control Servo Motor Circuit

DESCRIPTION

The rear air mix control servo motor (water valve servo motor) is controlled

by the A/C amplifier.

The rear air mix control servo motor moves the air mix damper by rotating

(normal ...

Compressor Solenoid Circuit

Compressor Solenoid Circuit

DESCRIPTION

In this circuit, the compressor receives a refrigerant compression demand

signal from the A/C amplifier.

Based on this signal, the compressor changes the amount of compressor output. ...

Other materials:

Canceling the rear moon roof operation (vehicles with the rear

moon roof)

Press the switch to disable the

rear moon roof operation from the

rear seat.

Pressing the switch again will

enable the operation again.

The moon roof can be operated when

The engine switch is in the “ON” position (vehicles without a smart key

system)

or IGNITION ON mode (vehicles ...

Short in Rear Curtain Shield Squib RH Circuit

DTC B1630/83 Short in Rear Curtain Shield Squib RH Circuit

DESCRIPTION

The rear curtain shield squib RH circuit consists of the center airbag sensor

assembly and the curtain

shield airbag assembly RH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B1630/83 ...

Pressure Control Solenoid "D" Electrical (Shift

Solenoid Valve SLT)

DESCRIPTION

The linear solenoid valve (SLT) controls the transmission line pressure for

smooth transmission operation

based on signals from the throttle position sensor and the vehicle speed sensor.

The ECM adjusts the

duty cycle of the SLT solenoid valve to control hydraulic line pressure co ...