Toyota Sienna Service Manual: Diagnosis Circuit

DESCRIPTION

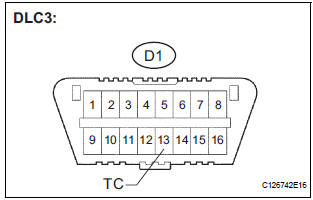

DTC output mode is set by connecting terminals TC and CG of the DLC3.

DTCs are displayed by blinking the SRS warning light.

HINT:

- When each warning light stays blinking, a ground short in the wiring of terminal TC of the DLC3 or an internal ground short in each ECU is suspected.

- A DTC output mode signal is transmitted through BEAN and CAN to each ECU including the center airbag sensor assembly. Thus when all systems do not enter DTC output mode, there may be an ECM malfunction

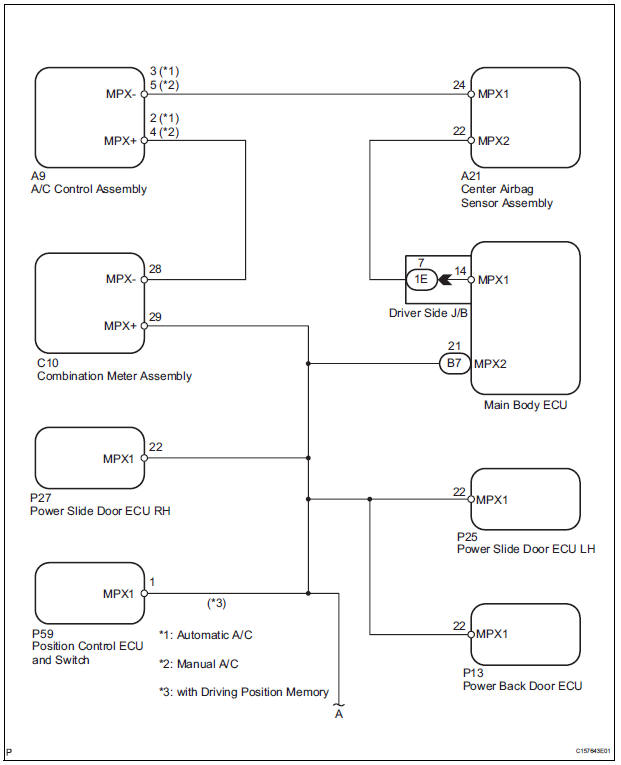

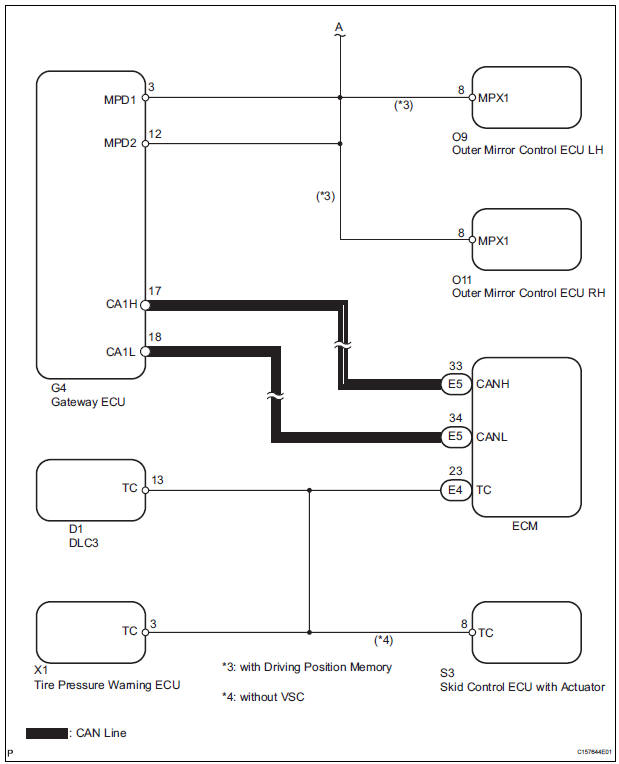

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK MULTIPLEX COMMUNICATION SYSTEM

- Check if the multiplex communication system DTC is output.

HINT: The center airbag sensor assembly of this system is connected to the multiplex communication system.

Therefore, before starting troubleshooting, make sure to check that there is no trouble in the multiplex communication system.

OK: The Multiplex communication system DTC is not output.

REPAIR CIRCUITS INDICATED BY

OUTPUT

DTCS

REPAIR CIRCUITS INDICATED BY

OUTPUT

DTCS

2 CHECK CAN COMMUNICATION SYSTEM

- Use the intelligent tester to check if the CAN communication system is functioning normally.

HINT: The ECM is connected to the CAN communication system. Therefore, before starting troubleshooting, make sure to check that there is no trouble in the CAN communication system.

OK: The CAN communication system is functioning normally.

REPAIR CAN COMMUNICATION

CIRCUIT

REPAIR CAN COMMUNICATION

CIRCUIT

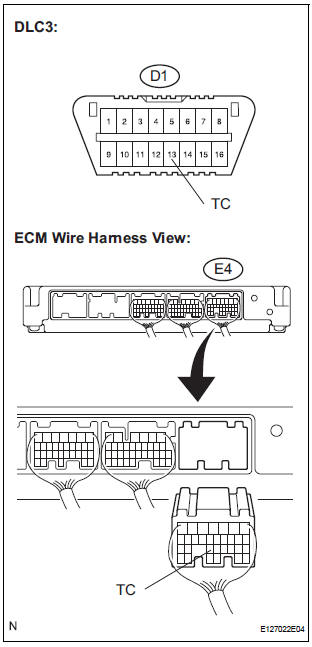

3 CHECK WIRE HARNESS (TC OF DLC3 - TC OF ECM)

- Turn the ignition switch to the LOCK position.

- Disconnect the connector from the ECM.

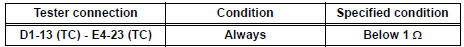

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPAIR OR REPLACE WIRE

HARNESS (TC

OF DLC3 - TC OF ECM)

REPAIR OR REPLACE WIRE

HARNESS (TC

OF DLC3 - TC OF ECM)

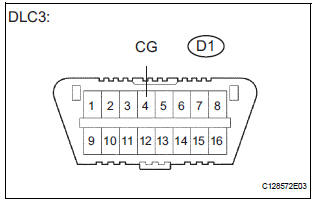

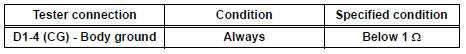

4 CHECK WIRE HARNESS (CG OF DLC3 - BODY GROUND)

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPAIR OR REPLACE WIRE

HARNESS (CG

OF DLC3 - BODY GROUND)

REPAIR OR REPLACE WIRE

HARNESS (CG

OF DLC3 - BODY GROUND)

5 CHECK WIRE HARNESS (TC OF DLC3 - BODY GROUND)

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPAIR OR REPLACE WIRE

HARNESS OR

EACH ECU

REPAIR OR REPLACE WIRE

HARNESS OR

EACH ECU

REPLACE CENTER AIRBAG SENSOR ASSEMBLY

SRS Warning Light does not Come ON

SRS Warning Light does not Come ON

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK BATTERY

Measure the voltage of the battery.

Standard voltage:

11 to 14 V

CHECK AND REPLACE BATTERY OR

CHARGING SYSTEM

2 CHECK CO ...

Other materials:

Terminals of ECU

1. POSITION CONTROL ECU AND SWITCH ASSEMBLY

(POWER SEAT CONTROL SWITCH AND ECU)

Disconnect the P58 and P59 connectors.

Check the voltage of each terminal of the wire

harness side connectors.

If the result is not as specified, there may be a

malfunction in the wire harn ...

Washer fluid

If any washer does not work or the

warning message appears on the

multi-information display, the

washer tank may be empty. Add

washer fluid.

WARNINGWhen refilling washer fluid

Do not refill washer fluid when the engine is hot or running, as

washer fluid

contains alcohol and ...

Speed sensor check (when using intelligent tester)

(a) Check the backward signal.

(1) Drive the vehicle in reverse for more than 1

second at 3 km/h (2 mph) or higher.

HINT:

Drive the vehicle in reverse and check the speed

sensor signal. Note that the signal check cannot

be completed if the vehicle speed is 45 km/h (28

mph) or more.

(b) Che ...