Toyota Sienna Service Manual: Disassembly

1. Remove rear wheel

2. Drain brake fluid

Notice: wash the brake fluid off immediately if it attaches to any painted surface.

3. REMOVE REAR BRAKE DRUM SUB-ASSEMBLY

(a) Release the parking brake lever, and remove the rear brake drum.

HINT: If the rear brake drum cannot be removed easily, perform the following procedure.

(b) Remove the hole plug and insert a screwdriver through the hole in the backing plate, and hold the automatic adjusting lever away from the adjuster.

(c) Using another screwdriver, reduce the brake shoe adjuster by turning the adjusting wheel.

4. REMOVE FRONT BRAKE SHOE

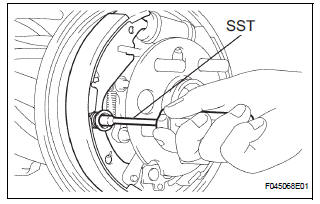

(a) Using SST, remove the shoe return spring from the front brake shoe.

SST 09921-00010

(b) Using a needle-nose pliers, remove the return spring.

(c) Using SST, remove the shoe hold down spring cup, shoe hold down spring and pin.

SST 09718-00010 (d) Remove the parking brake shoe strut LWR.

(e) Remove the tension spring and front brake shoe.

(f) Remove the automatic adjust lever spring and rear brake automatic adjust lever LH from the front brake shoe.

5. REMOVE REAR BRAKE SHOE

(a) Using SST, remove the shoe hold down spring cup, shoe hold down spring and pin.

SST 09718-00010

(b) Using a needle-nose pliers, disconnect the parking brake cable No. 3 and remove the rear brake shoe.

(c) Using a screwdriver, remove the 2 C-washers, parking brake shoe lever, parking brake reaction lever LH and rear brake strut set.

6. REMOVE LH, FRONT OR UPPER REAR WHEEL BRAKE CYLINDER ASSEMBLY

(a) Using SST, disconnect the brake tube, use a container to catch the brake fluid.

SST 09023-00101

(b) Remove the 2 bolts and rear wheel brake cylinder assembly.

7. REMOVE REAR WHEEL CYLINDER CUP KIT

(a) Remove the 2 cylinder dust boots from the rear wheel brake cylinder assembly.

(b) Remove the 2 pistons and compression spring.

(c) Remove the 2 wheel cylinder cups from each piston.

(d) Remove the bleeder plug cap and bleeder plug from the rear wheel brake cylinder assembly.

Rear drum brake

Rear drum brake

Components

...

Inspection

Inspection

1. INSPECT BRAKE DRUM INSIDE DIAMETER

(a) Using a brake drum gauge or equivalent, measure

the inside diameter of the drum.

Standard inside diameter:

254.0 mm (10.00 in.)

Maximum inside diamet ...

Other materials:

Fail-safe chart

1. FAIL-SAFE

This function minimizes the loss of the ECT functions

when any malfunction occurs in a sensor or solenoid.

(a) ATF (Automatic Transmission Fluid) temperature

sensor:

When the ATF temperature sensor has a

malfunction, 5th upshift is prohibited.

(b) Counter gear speed sensor NC ...

Short to GND in Side Squib RH Circuit

DTC B0112/41 Short to GND in Side Squib RH Circuit

DESCRIPTION

The side squib RH circuit consists of the center airbag sensor assembly and

the front seat side airbag

assembly RH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0112/41 is recorded when a sh ...

Memory Switch Circuit

DESCRIPTION

When the seat memory switch M1 or M2 is pressed, the position control ECU &

switch (Seat ECU)

transmits a signal of the memorized mirror position to the outer mirror control

ECU. Then, the outer mirror

control ECU drives the mirror motor.

HINT:

The power mirror control syste ...