Toyota Sienna Service Manual: Disassembly

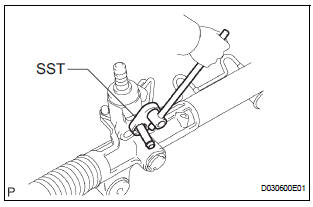

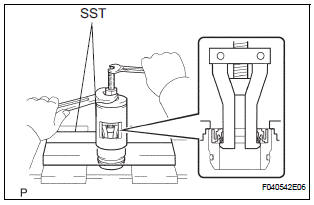

1. REMOVE RETURN TUBE NO.2

(a) Using SST, remove the return tube No. 2.

SST 09023-12701

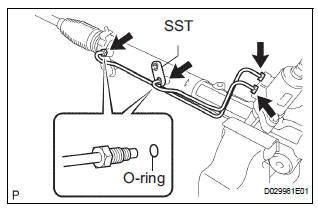

2. REMOVE STEERING LEFT TURN PRESSURE TUBE

(a) Using SST, remove the left turn pressure tube.

SST 09023-38201 (b) Remove the 2 O-rings from the left turn pressure tube.

3. REMOVE STEERING RIGHT TURN PRESSURE TUBE SST 09023-38201

HINT: Perform the same procedure on the other side.

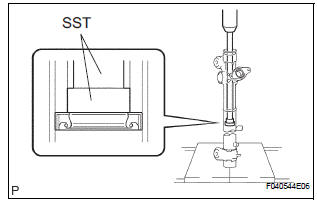

4. FIX RACK & PINION POWER STEERING GEAR ASSEMBLY

(a) Using SST, secure the power steering gear assembly.

SST 09612-00012

HINT: Tape the SST before use.

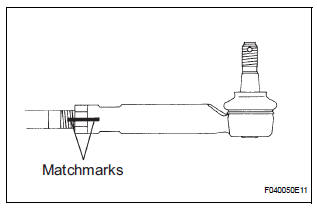

5. REMOVE TIE ROD ASSEMBLY LH

(a) Place matchmarks on the tie rod assembly and rack end sub-assembly.

(b) Loosen the lock nut, and remove the tie rod assembly and lock nut.

6. REMOVE TIE ROD ASSEMBLY RH

HINT: Perform the same procedure on the other side.

7. REMOVE STEERING RACK BOOT CLIP

(a) Remove the 2 rack boot clips.

8. REMOVE STEERING RACK BOOT NO.2 CLAMP

(a) Using pliers, remove the rack boot No. 2 clamp.

NOTICE: Be careful not to damage the steering rack boot No. 2.

9. REMOVE STEERING RACK BOOT NO.1 CLAMP

HINT: Perform the same procedure on the other side.

10. REMOVE STEERING RACK BOOT NO.2

11. REMOVE STEERING RACK BOOT NO.1

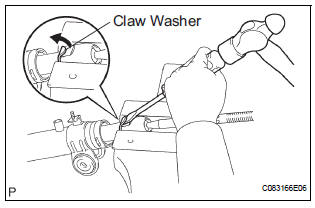

12. REMOVE STEERING RACK END SUB-ASSEMBLY

(a) Using a screwdriver and a hammer, unstake the claw washer.

NOTICE: Avoid any impact to the power steering rack.

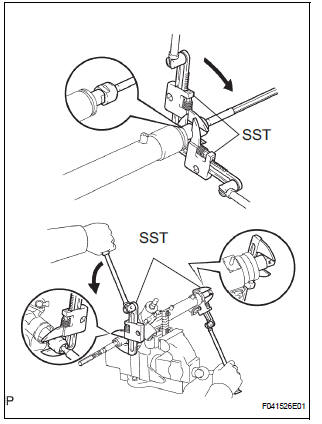

(b) Using 2 SST, remove the 2 steering rack end subassembly and 2 claw washers.

SST 09922-10010

NOTICE:

- Use SST 09922-10010 in the direction shown in the illustration.

- Securely hold the power steering rack end with a SST.

13. REMOVE RACK GUIDE

(a) Using SST, remove the rack guide spring cap nut.

SST 09922-10010

NOTICE: Use SST 09922-10010in the direction shown in the illustration.

(b) Using SST, remove the rack guide spring cap.

SST 09631-10021 (c) Remove the compression spring and the rack guide.

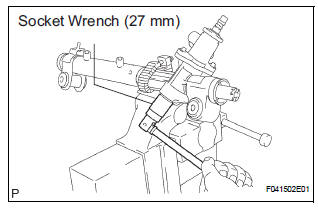

14. REMOVE POWER STEERING CONTROL VALVE

(a) Using a socket wrench (27 mm), remove the rack housing cap.

(b) Using SST, hold the control valve and remove the nut.

SST 09616-00011

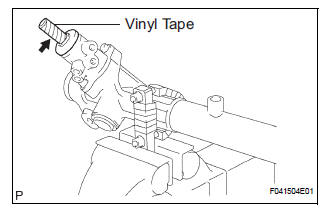

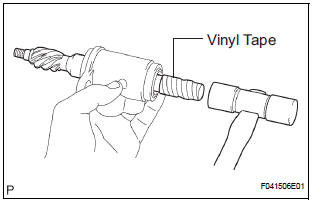

(c) Wind vinyl tape around the serrated part of the control valve.

(d) Remove the dust cover from the control valve housing.

(e) Remove the 2 bolts and the control valve w/ control valve housing.

(f) Remove the gasket.

(g) To prevent oil seal lip damage, wind vinyl tape around the serrated part of the control valve.

(h) Using a plastic hammer, remove the control valve w/ oil seal from the control valve housing.

(i) Remove the oil seal from the control valve.

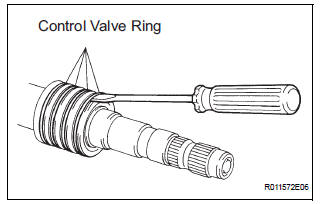

(j) Using a screwdriver, remove the 4 control valve rings.

NOTICE: Be careful not to damage the grooves for the control valve rings.

15. REMOVE POWER STEERING CONTROL VALVE UPPER OIL SEAL

(a) Using SST and a press, remove the control valve upper bearing and control valve upper oil seal from the control valve housing.

SST 09950-70010 (09951-07150), 09950-60010 (09951-00250)

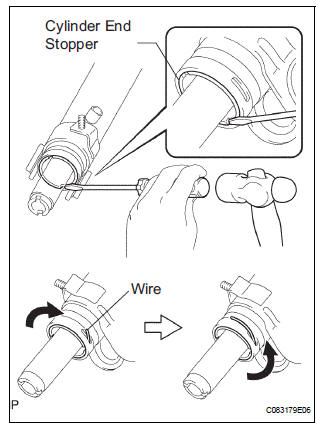

16. REMOVE CYLINDER END STOPPER

(a) Using a screwdriver and a hammer, turn the cylinder end stopper clockwise until the wire end is visible through the service hole.

(b) Using a screwdriver and a hammer, turn the cylinder end stopper counterclockwise, and remove the wire and cylinder end stopper

17. REMOVE POWER STEERING RACK

18. REMOVE POWER STEERING RACK BUSH

(a) Remove the rack bush from the power steering rack.

(b) Using SST, remove the rack bush oil seal.

SST 09527-21011, 09612-24014 (09613-22011) (c) Using a screwdriver, remove the O-ring from the rack bush.

19. REMOVE POWER STEERING CYLINDER TUBE OIL SEAL

(a) Using SST and a press, remove the cylinder tube oil seal.

SST 09950-70010 (09951-07360), 09950-60010 (09951-00290)

20. REMOVE RACK STEERING PISTON RING

(a) Using a screwdriver, remove the rack steering piston ring and O-ring.

NOTICE: Be careful not to damage the grooves for rack steering piston ring.

Removal

Removal

NOTICE:

When installing, coat the parts indicated by the arrows

with power steering fluid or molybdenum disulfide

lithium base grease (See page PS-21).

1. INSPECT CENTER FRONT WHEEL

2. REMOVE FRO ...

Inspection

Inspection

1. INSPECT POWER STEERING RACK

(a) Using a dial indicator, check the power steering rack

for runout and for teeth wear and damage.

Maximum runout:

0.3 mm (0.012 in.)

If necessary, replace t ...

Other materials:

Road test

1. PROBLEM SYMPTOM CONFIRMATION

Inspect the SET function.

Turn the cruise control main switch on.

Drive at the required speed between 40 km/h

(25 mph) and 200 km/h (125 mph).

Push the cruise control main switch to -

(COAST)/SET.

After releasing t ...

Installing the second seats

Installing the second outside seats

Align the marking on the seat side cover to the marking on the

rail cover and align the marking on the seat front/back cover to

the rail.

Tip-up seat

Ottoman seat

Lower the seat and engage the latches.

If you locked the seat lat ...

Initialization

1. RESET

When the battery is reconnected:

The back door is locked and therefore cannot be

opened. Therefore, it is necessary to unlock the

back door using the door control switch or

transmitter switch.

Reset the power back door system:

The power back door ECU records the ...