Toyota Sienna Service Manual: Disassembly

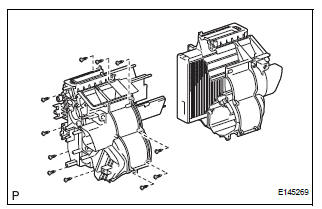

1. REMOVE BLOWER ASSEMBLY

(a) Remove the 2 screws and the blower assembly.

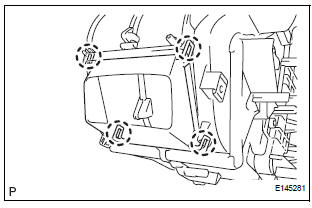

2. REMOVE MODE DAMPER SERVO SUB-ASSEMBLY

(a) Remove the 3 screws and the mode damper servo sub-assembly.

3. REMOVE AIRMIX DAMPER SERVO SUB-ASSEMBLY

(a) Remove the 3 screws and the airmix damper servo sub-assembly.

4. REMOVE NO. 2 AIRMIX DAMPER SERVO SUBASSEMBLY (for Automatic Air Conditioning System)

(a) Remove the 3 screws and the No. 2 airmix damper servo sub-assembly.

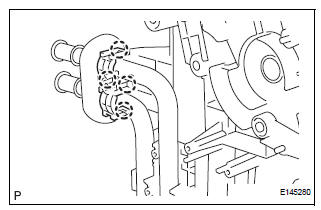

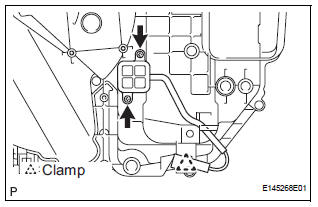

5. REMOVE NO. 1 HEATER CLAMP

(a) Release the 4 claw fittings and remove the No. 1 heater clamp.

6. REMOVE NO. 3 AIR CONDITIONING RADIATOR BRACKET

(a) Remove the screw and the No. 3 air conditioning radiator bracket.

7. REMOVE HEATER RADIATOR UNIT SUB-ASSEMBLY

(a) Remove the heater radiator unit sub-assembly from the air conditioning radiator assembly.

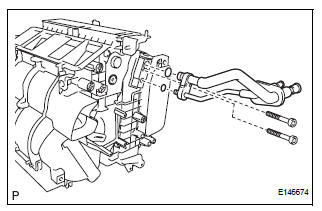

8. REMOVE AIR CONDITIONING TUBE ASSEMBLY

(a) Using a hexagon wrench 4.0 mm (0.15 in.), remove the 2 hexagon bolts and the air conditioning tube assembly.

(b) Remove the 2 O-rings from the air conditioning tube assembly.

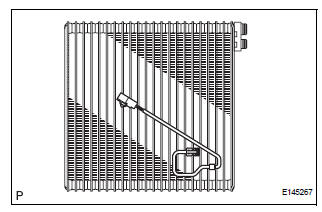

9. REMOVE COOLER EXPANSION VALVE

(a) Remove the cooler expansion valve from the No. 1 cooler evaporator sub-assembly.

(b) Remove the 2 O-rings from the No. 1 cooler evaporator sub-assembly.

10. REMOVE NO. 2 AIR CONDITIONING RADIATOR BRACKET

(a) Remove the 2 screws and the No. 2 air conditioning radiator bracket.

11. REMOVE NO. 1 AIR CONDITIONING RADIATOR BRACKET

(a) Remove the 3 screws and the No .1 air conditioning radiator bracket.

12. REMOVE NO. 4 AIR CONDITIONING RADIATOR BRACKET

(a) Remove the No. 4 air conditioning radiator bracket.

13. REMOVE NO. 1 AIR DUCT

(a) Release the 4 claw fittings and remove the No. 1 air duct.

14. REMOVE NO. 1 COOLER THERMISTOR

(a) Disengage the clamp.

(b) Remove the 2 screws.

(c) Remove the 11 screws.

(d) Remove the No. 1 cooler thermistor.

Removal

Removal

1. RECOVER REFRIGERANT FROM REFRIGERATION

SYSTEM (See page AC-172)

2. REMOVE FRONT WIPER ARM HEAD CAP (See page

WW-4)

3. REMOVE FRONT WIPER ARM RH (See page WW-4)

4. REMOVE FRONT WIPER ARM LH (Se ...

Reassembly

Reassembly

1. INSTALL NO. 1 COOLER THERMISTOR

(a) Install the No. 1 cooler thermistor as shown in the

illustration.

NOTICE:

Be sure to insert the thermistor only once

because reinserting it will no ...

Other materials:

Radiator

COMPONENTS

...

Installation

1. INSTALL TIRE PRESSURE WARNING RECEIVER ASSEMBLY

(a) Connect the connector.

(b) Install the tire pressure warning receiver assembly

with the bolt.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

2. INSTALL ROOF HEADLINING ASSEMBLY

HINT:

Refer to the instructions for INSTALLATION of the ROOF ...

Diagnosis system

1. CHECK DLC3

The vehicle uses ISO 15765-4 communication

protocol.

The terminal arrangement of the DLC3 complies

with SAE 1962 and matched the ISO 15765-4

format.

If the result is not as specified, the DLC3 may have

a malfunction. Repair or replace the harness and

connecto ...