Toyota Sienna Service Manual: Disassembly

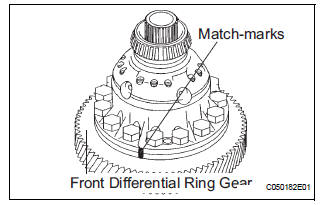

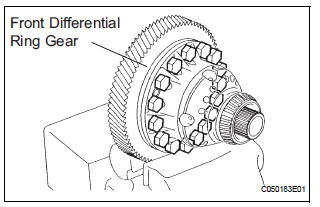

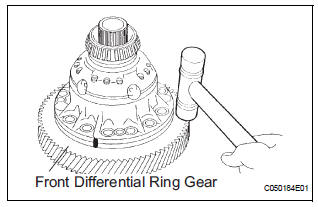

1. REMOVE FRONT DIFFERENTIAL RING GEAR

(a) Place the match-marks on the ring gear and differential case.

(b) Remove the 16 bolts.

(c) Using a plastic hammer, tap ring gear to remove it from the case.

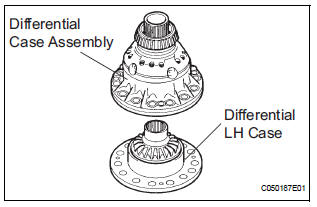

2. REMOVE FRONT DIFFERENTIAL SIDE GEAR

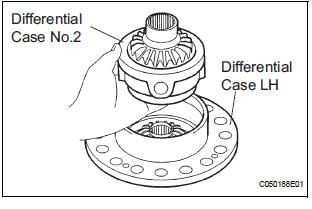

(a) Remove the differential LH case from the differential case assembly.

(b) Remove the differential case No.2 from the differential case LH.

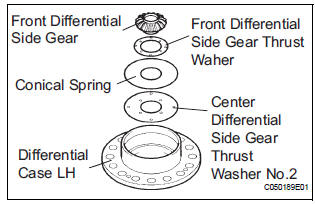

(c) Remove the front differential side gear, front differential side gear thrust washer, conical spring and center differential side gear thrust washer No.2 from the differential case LH.

(d) Using a snap ring expander, remove the pinion shaft spacer snap ring.

(e) Using a pin punch and hammer, remove 3 straight pins.

(f) Remove the center differential pinion shaft and 2 differential pinion shafts.

(g) Remove 4 front differential pinions, 4 front differential pinion thrust washers, front differential pinion shaft holder, front differential planetary ring and differential side gear thrust washer No.1.

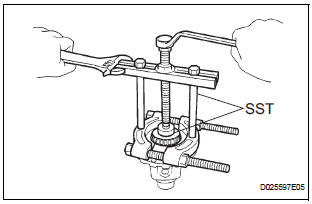

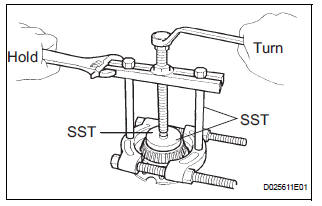

3. REMOVE FRONT DIFFERENTIAL CASE REAR TAPERED ROLLER BEARING

(a) Using SST, remove the front differential case rear tapered roller bearing from the differential case.

SST 09950-00020, 09950-00030, 09950-60010 (09951-00480)

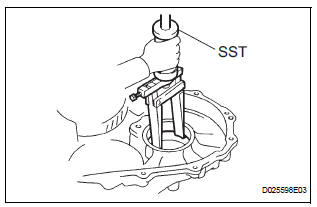

(b) Using SST, remove the front differential case rear tapered roller bearing outer race and differential case washer

SST 09308-00010

4. REMOVE CENTER DIFFERENTIAL PINION

(a) Using torx socket (T50), remove the 15 bolts.

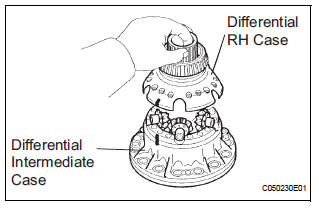

(b) Place the matchmarks on the differential intermediate case and differential case.

(c) Remove the differential intermediate case from the differential case RH.

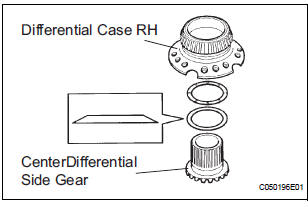

(d) Remove the center differential side gear, conical spring washer and center differential side gear thrust washer No.1 RH from the differential case RH.

(e) Remove the differential spider, 5 center differential pinions and 5 center differential pinion thrust washers from the differential intermediate case.

5. REMOVE FRONT DIFFERENTIAL CASE FRONT TAPERED ROLLER BEARING

(a) Using SST, remove the front differential case front tapered roller bearing from the differential case.

SST 09950-00020, 09950-00030 SST 09950-60010 (09951-00600)

(b) Using SST, remove the front differential case front tapered roller bearing outer race and differential case washer.

SST 09308-00010

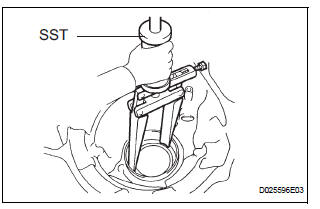

6. REMOVE TRANSAXLE HOUSING OIL SEAL

(a) Using SST, remove the oil seal.

SST 09950-70010 (09951-07100) SST 09649-17010

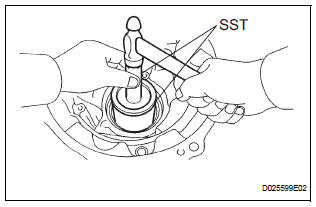

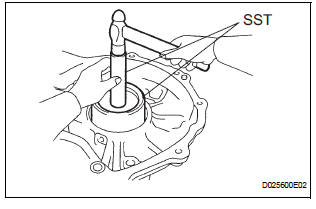

7. REMOVE DIFFERENTIAL SIDE BEARING RETAINER OIL SEAL

(a) Using SST, remove the oil seal.

SST 09950-70010 (09951-07100), 09608-10010

Differential case

Differential case

COMPONENTS

...

Inspection

Inspection

1. INSPECT FRONT DIFFERENTIAL

(a) Using a dial indicator, measure the backlash of one

pinion gear while holding the front differential side

gear toward the case.

Standard backlash:

0.05 - 0.2 ...

Other materials:

Disassembly

1. Remove repair service starter kit

(a) Remove the nut and disconnect the lead wire from

the repair service starter kit.

(b) Remove the 2 screws which are used to secure the

repair service starter kit to the repair service starter

kit.

(c) Remove the repair service starter kit.

( ...

Throttle Actuator Control Motor Current Range

/ Performance

DTC P2118 Throttle Actuator Control Motor Current Range

/ Performance

DESCRIPTION

The ETCS (Electronic Throttle Control System) has a dedicated power supply

circuit. The voltage (+BM)

is monitored and when it is low (less than 4 V), the ECM determines that there

is a malfunction in the

ETCS ...

Disassembly

1. REMOVE RADIATOR WATER INLET

(a) Remove the 2 bolts and radiator water inlet.

2. REMOVE DRAIN PLUG

(a) Remove the drain plug and air drain plug.

(b) Remove the 2 O-rings.

3. REMOVE LOWER RADIATOR TANK

(a) Install the claw to the overhaul handle, inserting it in

the hole in Part A ...