Toyota Sienna Service Manual: Disassembly

1. REMOVE PROPELLER SHAFT ASSEMBLY

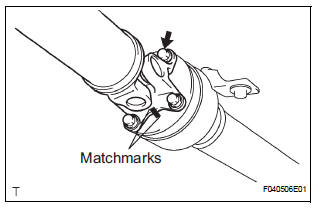

(a) Put matchmarks on both the flanges.

(b) Remove the 4 nuts, bolts and washers.

2. REMOVE INTERMEDIATE SHAFT

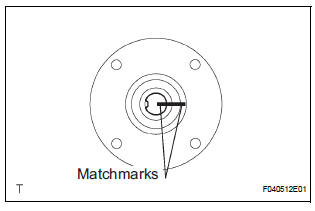

(a) Put matchmarks on the propeller shaft subassembly and universal joint flange.

NOTICE: Do not use a punch for the marks.

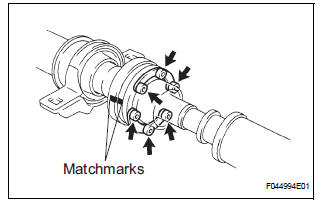

(b) Using a hexagon wrench (6 mm), remove the 6 bolts and 2 washers and separate the intermediate shaft from the propeller shaft assembly rear.

3. REMOVE CENTER SUPPORT BEARING ASSEMBLY NO.1

(a) Using a chisel and a hammer, loosen the staked part of the nut.

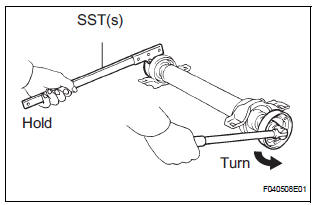

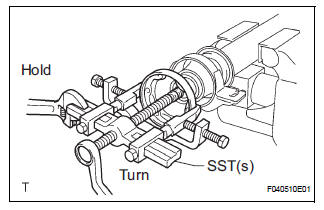

(b) Using SST(s) to hold the front flange, remove the nut and plate washer.

SST 09330-00021

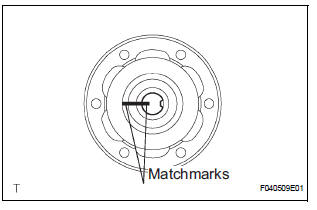

(c) Put matchmarks on the rear flange and shaft.

(d) Hold the intermediate shaft in a vise between aluminium plates.

NOTICE: Do not overtighten the vise

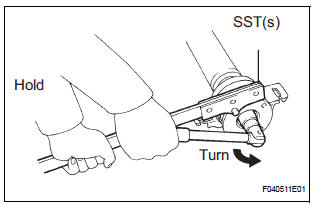

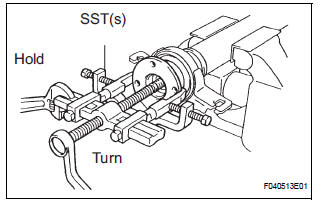

(e) Using SST(s), remove the rear flange.

SST 09950-40011 (09951-04020, 09952-04010, 09953-04030, 09954-04010, 09955-04061, 09957-04010, 09958-04011)

NOTICE: Be careful not to damage the universal joint flange.

(f) Remove the center support bearing assembly No. 1 (rear) and washer.

4. REMOVE CENTER SUPPORT BEARING ASSEMBLY NO.1

(a) Using a chisel and a hammer, loosen the staked part of the nut.

(b) Using SST(s) to hold the front flange, remove the nut and plate washer.

SST 09330-00021

(c) Put matchmarks on the front flange and shaft.

(d) Hold the intermediate shaft in a vise between aluminium plates.

NOTICE: Do not overtighten the vise.

(e) Using SST(s), remove the front flange.

SST 09950-40011 (09951-04020, 09952-04010, 09953-04030, 09954-04010, 09955-04061, 09957-04010, 09958-04011)

NOTICE: Be careful not to damage the universal joint flange.

(f) Remove the center support bearing assembly No. 1 (front) and washer.

Removal

Removal

1. REMOVE EXHAUST PIPE ASSEMBLY

(a) Remove exhaust pipe assembly (See page EX-8).

2. REMOVE PROPELLER W/CENTER BEARING SHAFT ASSEMBLY

(a) Depress the brake pedal and hold it down.

(b) Using ...

Inspection

Inspection

1. INSPECT SPIDER BEARING

(a) Check that the spider bearing moves smoothly by

turning the flange.

(b) Check for the looseness around the joint by strongly

moving the flange in the axial and ...

Other materials:

Operation check

1. ILLUMINATED ENTRY SYSTEM OPERATION CHECK

The illuminated entry system is explained below:

Turn the ignition switch OFF, close all the doors,

and set them in the lock condition.

Unlock any door and open any other doors and

check that the room light comes on. Close ...

Air outlet control servo motor

ON-VEHICLE INSPECTION

1. INSPECT AIR OUTLET CONTROL SERVO MOTOR

(a) Remove the air outlet control servo motor.

(b) Connect the positive (+) lead from the battery to

terminal 4 and negative (-) lead to terminal 5, then

check that the lever turns to "DEF" position.

(c) Connect ...

Transponder Chip Malfunction

DTC B2793 Transponder Chip Malfunction

DESCRIPTION

This DTC is output when a malfunction is found in the key during the key code

registration or the key code

is not registered normally. Replace the key when the key code registration is

not performed normally and

this DTC is detected.

IN ...