Toyota Sienna Service Manual: Removal

1. REMOVE EXHAUST PIPE ASSEMBLY

(a) Remove exhaust pipe assembly (See page EX-8).

2. REMOVE PROPELLER W/CENTER BEARING SHAFT ASSEMBLY

(a) Depress the brake pedal and hold it down.

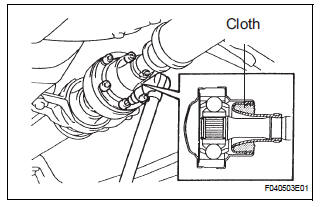

(b) Using a hexagon wrench (6 mm), loosen the cross groove joint set bolts a half turn.

HINT: Place a cloth in the inside of the universal joint cover so that the boot does not touch the inside of the universal joint cover.

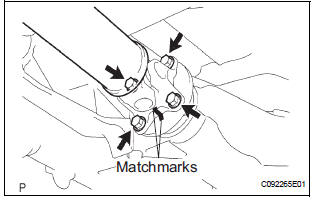

(c) Put matchmarks on both the flanges.

(d) Remove the 4 nuts, bolts and washers.

(e) Remove the 4 bolts, 2 adjusting shims and propeller shaft w/ center bearing shaft assembly.

NOTICE:

- When removing the propeller shaft, do not apply excessive force to the universal joint.

- During and after the removal of the propeller shaft, keep the universal joint angle straight (within 15 degrees).

- Be careful not to damage the oil seal.

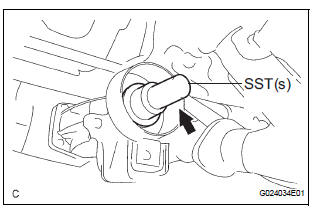

(f) Insert SST(s) in the transfer extension housing to prevent oil leakage.

SST 09325-20010

NOTICE: Be careful not to damage the oil seal.

Propeller shaft assembly (for 4wd)

Propeller shaft assembly (for 4wd)

COMPONENTS

...

Disassembly

Disassembly

1. REMOVE PROPELLER SHAFT ASSEMBLY

(a) Put matchmarks on both the flanges.

(b) Remove the 4 nuts, bolts and washers.

2. REMOVE INTERMEDIATE SHAFT

(a) Put matchmarks on the propeller shaf ...

Other materials:

Installation

1. INSTALL SLIDE DOOR ROLLER ASSEMBLY UPPER

Apply MP grease to the rotating areas of the roller.

Install the roller with the 2 bolts.

Torque: 13 N*m (130 kgf*cm, 10 ft.*lbf)

2. INSTALL SLIDE DOOR HINGE ASSEMBLY CENTER LH

Apply MP grease to the rotating areas of the hinge.

In ...

Towing related terms

GCWR (Gross Combination Weight Rating)

The maximum allowable gross

combination weight. The gross

combination weight is the sum

of the total vehicle weight

(including the occupants, cargo

and any optional equipment

installed on the vehicle) and the

weight of the trailer being towed

(incl ...

Precaution

1. HANDLING PRECAUTIONS ON STEERING SYSTEM

(a) Be careful to replace the parts properly because

they could affect the performance of the steering

system and result in a driving hazard.

2. HANDLING PRECAUTIONS ON SRS AIRBAG

SYSTEM

(a) The SIENNA is equipped with SRS (Supplemental

Restraint Sys ...