Toyota Sienna Service Manual: ECM Communication Stop Mode

DESCRIPTION

|

Detection Item |

Symptom |

Trouble Area |

| ECM Communication Stop Mode |

|

|

WIRING DIAGRAM

INSPECTION PROCEDURE

NOTICE:

- Turn the ignition switch off before measuring the resistances of CAN bus main wires and CAN bus branch wires.

- After the ignition switch is turned off, check that the key reminder warning system and light reminder warning system are not in operation.

- Before measuring the resistance, leave the vehicle as is for at least 1 minute and do not operate the ignition switch, any other switches, or the doors. If any doors need to be opened in order to check connectors, open the doors and leave them open.

HINT: Operating the ignition switch, any switches, or any doors triggers related ECU and sensor communication with the CAN. This communication will cause the resistance value to change.

1 CHECK OPEN IN CAN BUS WIRE (ECU MAIN BUS WIRE)

- Disconnect ECM connector (E5).

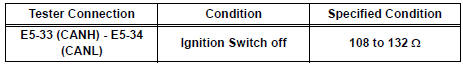

- Measure the resistance according to the value(s) in the table below.

Standard resistance

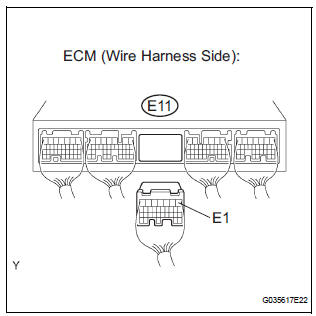

2 CHECK WIRE HARNESS (E1, BATT, +BM, IGSW)

- Disconnect the ECM connector (E11).

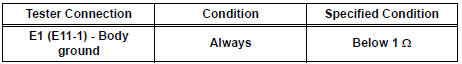

- Measure the resistance according to the value(s) in the table below.

Standard resistance

- Disconnect the ECM connector (E4).

- Measure the voltage according to the value(s) in the table below.

Standard voltage

REPLACE ECM

Yaw Rate Sensor Communication Stop Mode

Yaw Rate Sensor Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

Yaw Rate Sensor

Communication Stop

Mode

"Yaw rate/ Deceleration sensor" is not displayed ...

CAN Bus Line

CAN Bus Line

DESCRIPTION

When any DTC for the CAN communication system is output, first measure the

resistance between the

terminals of the DLC3 to specify the trouble area, and check that there is no

short ...

Other materials:

Rear Airbag Sensor RH Circuit Malfunction

DTC B1154/38 Rear Airbag Sensor RH Circuit Malfunction

DESCRIPTION

The rear airbag sensor RH circuit consists of the center airbag sensor

assembly and rear airbag sensor

RH.

If the center airbag sensor assembly receives signals from the rear airbag

sensor RH, it judges whether or

not the ...

Adjustment

HINT:

On the RH side, use the same procedures as on the LH

side.

Since a centering bolt is used as door hinge mounting

bolts on the body side and the door side, the door cannot

be adjusted with them on. Substitute a bolt with a washer

for the centering bolt.

1. INSPECT BACK DOOR PAN ...

Installation

1. INSTALL SLIDE DOOR ROLLER ASSEMBLY UPPER

Apply MP grease to the rotating areas of the roller.

Install the roller with the 2 bolts.

Torque: 13 N*m (130 kgf*cm, 10 ft.*lbf)

2. INSTALL SLIDE DOOR HINGE ASSEMBLY CENTER LH

Apply MP grease to the rotating areas of the hinge.

In ...