Toyota Sienna Service Manual: CAN Bus Line

DESCRIPTION

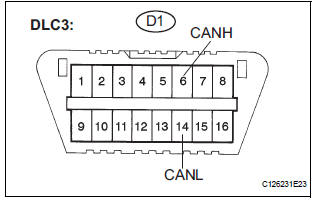

When any DTC for the CAN communication system is output, first measure the resistance between the terminals of the DLC3 to specify the trouble area, and check that there is no short in the CAN main wire, between the main wire, and +B or GND.

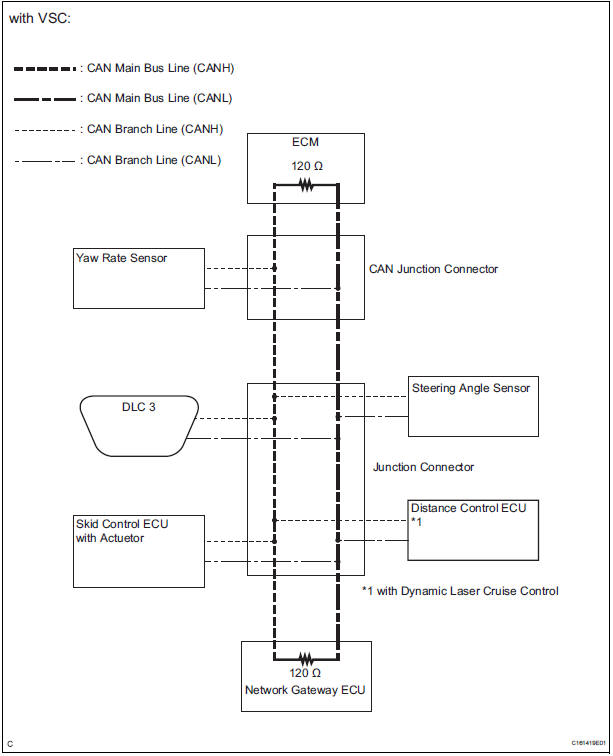

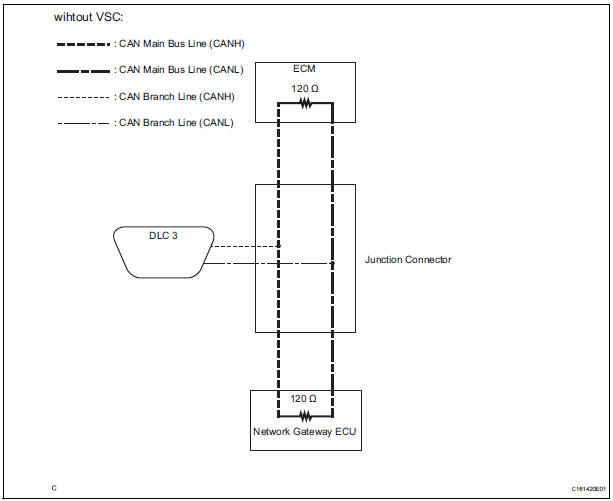

WIRING DIAGRAM

INSPECTION PROCEDURE

NOTICE:

- Turn the ignition switch off before measuring the resistances of CAN bus main wires and CAN bus branch wires.

- After the ignition switch is turned off, check that the key reminder warning system and light reminder warning system are not in operation.

- Before measuring the resistance, leave the vehicle as is for at least 1 minute and do not operate the ignition switch, any other switches, or the doors. If any doors need to be opened in order to check connectors, open the doors and leave them open.

HINT: Operating the ignition switch, any switches, or any doors triggers related ECU and sensor communication with the CAN. This communication will cause the resistance value to change.

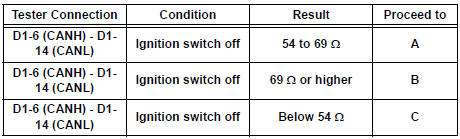

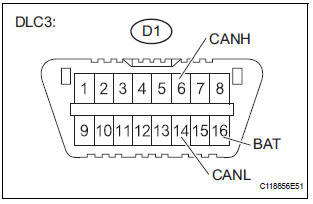

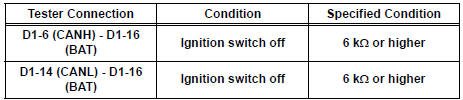

1 CHECK CAN BUS WIRE (MAIN WIRE FOR DISCONNECTION, CAN BUS LINES FOR SHORT CIRCUIT)

- Turn the ignition switch off.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

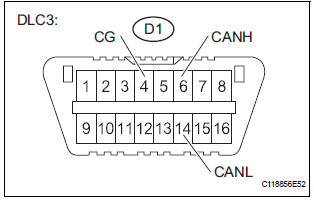

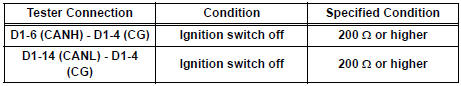

2 CHECK FOR SHORT TO B+ IN CAN BUS WIRE

- Measure the resistance according to the value(s) in the table below.

Standard resistance

3 CHECK FOR SHORT TO GND IN CAN BUS WIRE

- Measure the resistance according to the value(s) in the table below.

Standard resistance

GO TO HOW TO PROCEED WITH TROUBLESHOOTING

ECM Communication Stop Mode

ECM Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

ECM Communication Stop

Mode

"Engine" is not displayed on the "Communication

Bus Che ...

Open in CAN Main Bus Line

Open in CAN Main Bus Line

DESCRIPTION

There may be an open circuit in the CAN main bus wire and/or the DLC3 branch

wire when the resistance

between terminals 6 (CANH) and 14 (CANL) of the DLC3 is 69 Ω or higher.

...

Other materials:

Voice Guidance does not Function

INSPECTION PROCEDURE

1 CHECK NAVIGATION SYSTEM SETTING

Enter the "Menu" screen by pressing the "MENU" switch.

Select "Volume".

Check that "OFF" is not selected.

OK:

"OFF" is not selected

2 CHECK NAVIGATION SETTING

...

Removal

1. PRECAUTION

CAUTION: Be sure to read "PRECAUTION" thoroughly before

servicing.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait for 90 seconds after disconnecting the cable to

prevent the airbag working.

3. REMOVE FRONT SEAT ASSEMBLY (for Manual Seat)

4. REMOVE ...

Rear combination light assembly

COMPONENTS

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE REAR COMBINATION LIGHT ASSEMBLY

Remove the 2 bolts.

Disengage the 2 pins and separate the rear

combination light assembly as shown in the

illustration.

Disconnect the connector a ...