Toyota Sienna Service Manual: Evaporative Emission Control System Incorrect Purge Flow

DTC P0441 Evaporative Emission Control System Incorrect Purge Flow

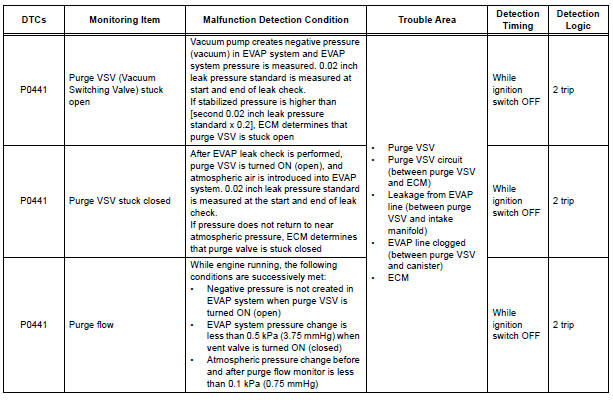

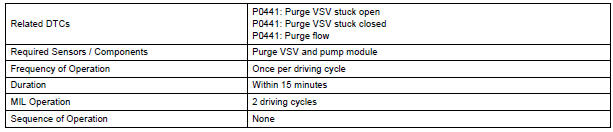

DTC SUMMARY

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission) System.

INSPECTION PROCEDURE

Refer to the EVAP System.

MONITOR DESCRIPTION

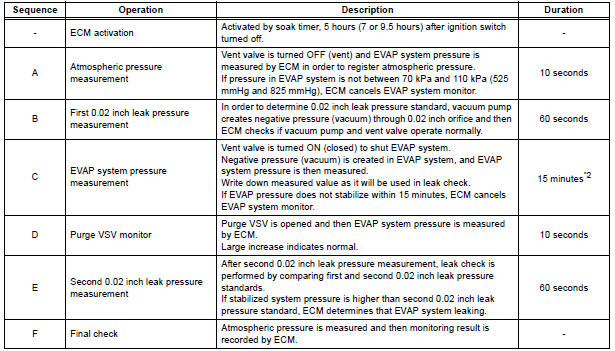

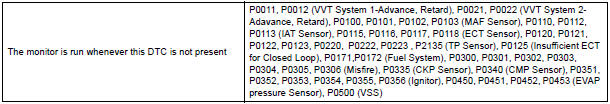

The two monitors, Key-Off and Purge Flow, are used to detect malfunctions relating to DTC P0441. The Key-off monitor is initiated by the ECM internal timer, known as the soak timer, 5 hours*1 after the ignition switch is turned off. The purge flow monitor runs while the engine is running.

1. KEY-OFF MONITOR

5 hours*1 after the ignition switch is turned off, the electric vacuum pump creates negative pressure (vacuum) in the EVAP (Evaporative Emission) system. The ECM monitors for leaks and actuator malfunctions based on the EVAP pressure.

HINT: *1: If the engine coolant temperature is not below 35C (95F) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35C (95F) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 hours later.

*2: If only a small amount of fuel is in the fuel tank, it takes longer for the EVAP pressure to stabilize.

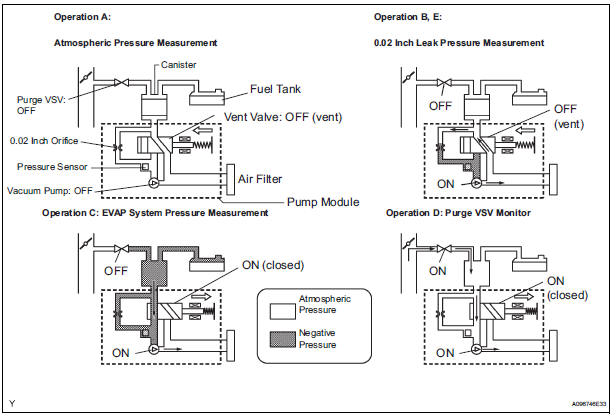

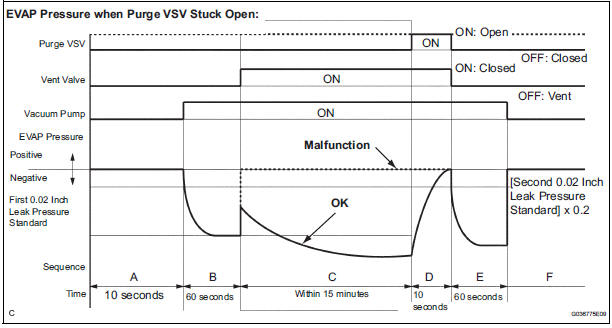

- Purge VSV stuck open

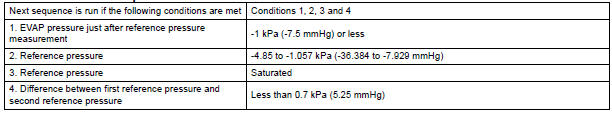

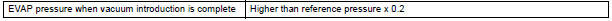

In operation C, the vacuum pump creates negative pressure (vacuum) in the EVAP (Evaporative Emission) system. The EVAP system pressure is then measured by the ECM using the pressure sensor. If the stabilized system pressure is higher than [second 0.02 inch leak pressure standard x 0.2], the ECM interprets this as the purge VSV (Vacuum Switching Valve) being stuck open.The ECM illuminates the MIL and sets the DTC (2 trip detection logic).

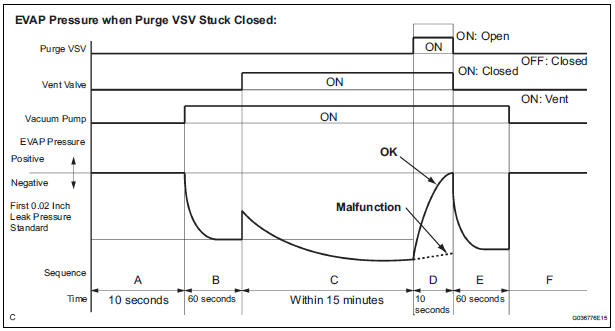

- Purge VSV stuck closed

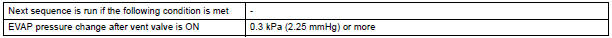

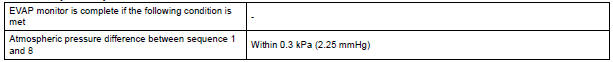

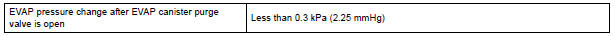

In operation D, the pressure sensor measures the EVAP (Evaporative Emission) system pressure. The pressure measurement for purge VSV monitor is begun when the purge VSV is turned on (open) after the EVAP leak check. When the measured pressure indicates an increase of 0.3 kPa (2.25 mmHg) or more, the purge VSV is functioning normally. If the pressure does not increase, the ECM interprets this as the purge VSV being stuck closed. The ECM illuminates the MIL and sets the DTC (2 trip detection logic).

2. PURGE FLOW MONITOR

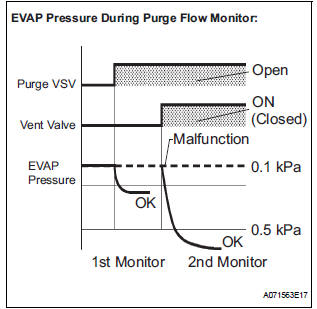

The purge flow monitor consists of the two step monitors.

The 1st monitor is conducted every time and the 2nd monitor is activated if necessary.

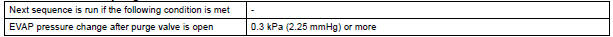

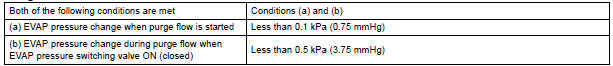

- The 1st monitor

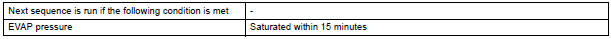

While the engine is running and the purge VSV (Vacuum Switching Valve) is on (open), the ECM monitors the purge flow by measuring the EVAP pressure change. If negative pressure is not created, the ECM begins the 2nd monitor. - The 2nd monitor

The vent valve is turned on (closed) and the EVAP pressure is then measured. If the variation in the pressure is less than 0.5 kPa (3.75 mmHg), the ECM interprets this as the purge VSV being stuck closed, and illuminates the MIL and sets DTC P0441 (2 trip detection logic).

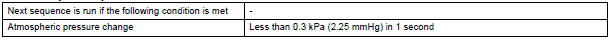

Atmospheric pressure check: In order to ensure reliable malfunction detection, the variation between the atmospheric pressures, before and after conduction of the purge flow monitor, is measured by the ECM.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

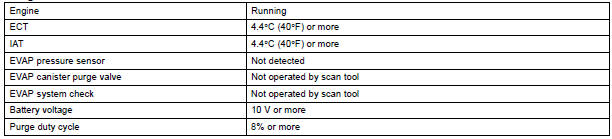

All:

Purge flow:

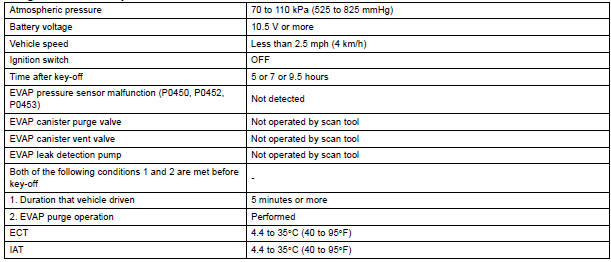

Purge VSV stuck open and closed:

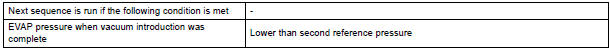

Key-off monitor sequence 1 to 8

1. Atmospheric pressure measurement

2. First reference pressure measurement

3. EVAP canister vent valve close stuck check

4. Vacuum introduction

5. EVAP canister purge valve close stuck check

6. Second reference pressure measurement

7. Leak check

8. Atmospheric pressure measurement

TYPICAL MALFUNCTION THRESHOLDS

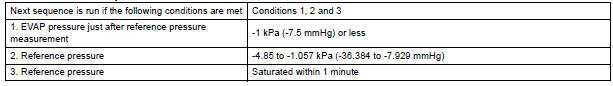

Purge flow:

EVAP VSV stuck open:

EVAP VSV stuck closed:

MONITOR RESULT

Refer to CHECKING MONITOR STATUS

Evaporative Emission System

Evaporative Emission System

DTC P043E Evaporative Emission System Reference Orifice

Clog Up

DTC P043F Evaporative Emission System Reference Orifice

High Flow

DTC P2401 Evaporative Emission System Leak Detection

Pump Control ...

Evaporative Emission Control System Pressure

Evaporative Emission Control System Pressure

DTC P0450 Evaporative Emission Control System Pressure

Sensor / Switch

DTC P0451 Evaporative Emission Control System Pressure

Sensor Range / Performance

DTC P0452 Evaporative Emission Control Syst ...

Other materials:

On-vehicle inspection

1. CHECK POWER MIRROR SWITCH OPERATION

Remote control

The mirror adjust switch can control the adjustment

axis of the mirror surface.

Reverse-linked

This function tilts the mirror surface downward to

improve the visibility when driving in reverse,

provided that all the co ...

Power Source Circuit

DESCRIPTION

This is the power source circuit for the outer mirror control ECU.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 INSPECT OUTER MIRROR CONTROL ECU (POWER SOURCE)

Disconnect the O9 or O11 ECU connector.

Measure the voltage and resistance according to the

value(s) in the t ...

Reassembly

1. INSTALL CENTER CLUSTER MODULE KNOB NO.6

(for Automatic Air Conditioning System)

2. INSTALL CENTER CLUSTER MODULE KNOB NO.5

(for Automatic Air Conditioning System)

3. INSTALL CLOCK ORNAMENT

4. INSTALL PRINTED WIRE INTEGRATION BOARD

SUB-ASSEMBLY (for Automatic Air Conditioning

System)

5. IN ...